MAINTENANCE SECTION

4.Clean the threads on the Arbor; apply a film of thread locking compound to the threads. Screw the Bevel Gear Nut (48) onto the Arbor and tighten to 8.5 to 11.5

5.Grasp the Angle Arbor Housing (43) in or

(46)and Upper Arbor Bearing (47).

6.If replacement of the Mounting Plate Pin (45) is necessary, press a new pin into the Angle Arbor Housing.

7.Install the assembled Depressed Center Wheel Arbor

(55)into the Angle Arbor Housing.

8.Place the Sander Arbor Retaining Plate (52) in position on the Angle Arbor Housing.

9.Install the Screw Lock Washers (53) and Retaining Plate Screws. Tighten to 7.5 to 8

10.Install the Pad Mounting Kit Spacers (57) and Sanding Pad Assembly (56).

For GRP15A Models, install the Wool Bonnet (58).

11.Using the No.

12.Insert a 5” (127 mm) long 3/16” hex wrench into the elongated slot in the end of the Dead Handle (70) and into the hex recess in the screw head.

13.Position the Handle against the Angle Arbor Housing (43) and thread the screw into the Housing. The Handle can be attached at either of two positions 180 degrees apart. Select the desired position and tighten the screw to 18

14.Apply approximately 5 cc of IRAX No.

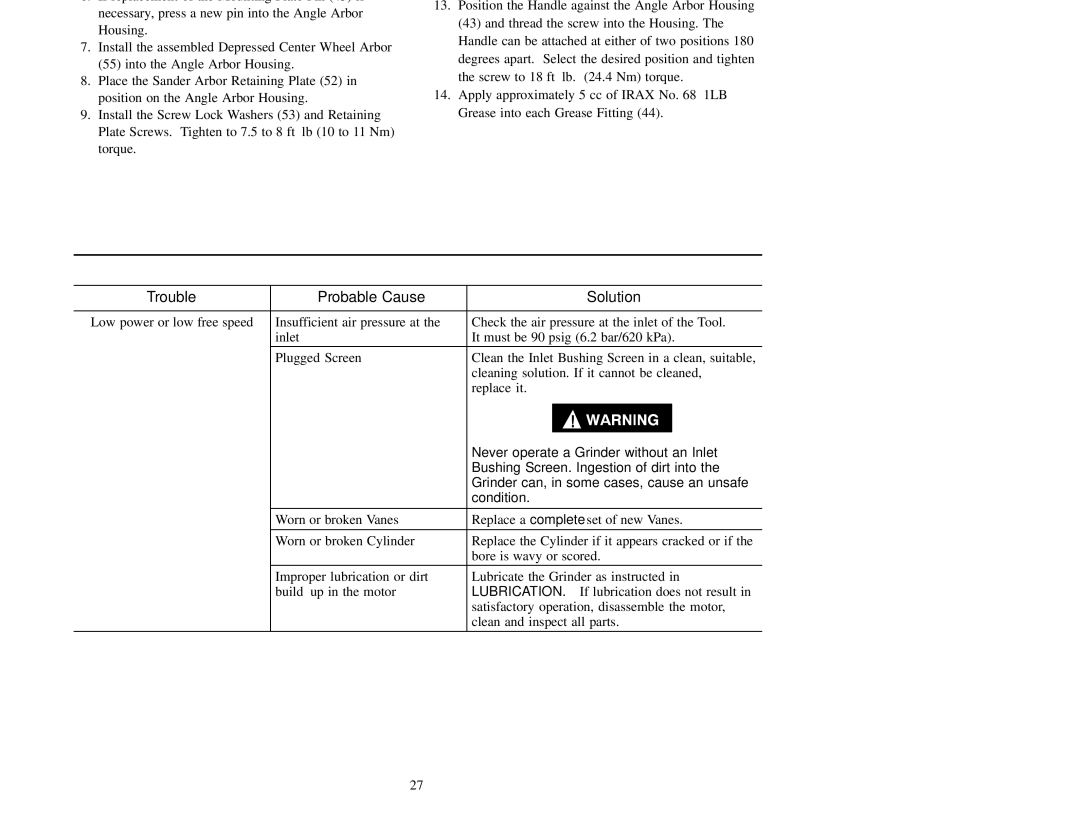

TROUBLESHOOTING GUIDE

Trouble | Probable Cause |

| Solution | |

|

|

|

|

|

Low power or low free speed | Insufficient air pressure at the | Check the air pressure at the inlet of the Tool. | ||

| inlet | It must be 90 psig (6.2 bar/620 kPa). | ||

|

|

|

|

|

| Plugged Screen | Clean the Inlet Bushing Screen in a clean, suitable, | ||

|

| cleaning solution. If it cannot be cleaned, | ||

|

| replace it. | ||

|

|

|

|

|

|

|

|

|

|

| Never operate a Grinder without an Inlet |

| Bushing Screen. Ingestion of dirt into the |

| Grinder can, in some cases, cause an unsafe |

| condition. |

|

|

Worn or broken Vanes | Replace a complete set of new Vanes. |

|

|

Worn or broken Cylinder | Replace the Cylinder if it appears cracked or if the |

| bore is wavy or scored. |

|

|

Improper lubrication or dirt | Lubricate the Grinder as instructed in |

LUBRICATION. If lubrication does not result in | |

| satisfactory operation, disassemble the motor, |

| clean and inspect all parts. |

27