SANDER/POLISHER SPECIFIC WARNINGS

M10

180

• These Sanders and Polishers will operate at the free | accessory having a maximum operating speed less |

speed specified on the nameplate if the air supply | than the free speed of the Sander or Polisher in |

line furnishes 90 psig (6.2 bar/620 kPa) air pressure | which it is being used. |

at the tool. Operation at higher air pressure will | • When using a pad on a threaded arbor, make |

result in excessive speed. | certain the flange nut is tightened securely. Check |

• Use only a sanding pad, buffing wheel or polishing | the tightness of the flange nut before operating a |

bonnet with these tools. Do not use any grinding | Sander to make certain it will not loosen during |

wheel, bur or metal removing accessory other than | operation. |

a sanding pad with these tools. Never use an |

|

WARNING: Incorrect combinations of grinding wheel, wheel guard and tool speed could result in injury. Correct combinations are specified below:

Guard Part Number | Wheel Type | Wheel Diameter | Maximum Wheel | Maximum Speed |

|

| in. (mm) | Thickness | rpm |

|

|

| in. (mm) |

|

|

|

|

|

|

27, 28 | 7 (178) | 1/4 (6.4) | 7,500 | |

|

|

|

|

|

27, 28 | 7 (178) | 1/4 (6.4) | 6,000 |

PLACING TOOL IN SERVICE

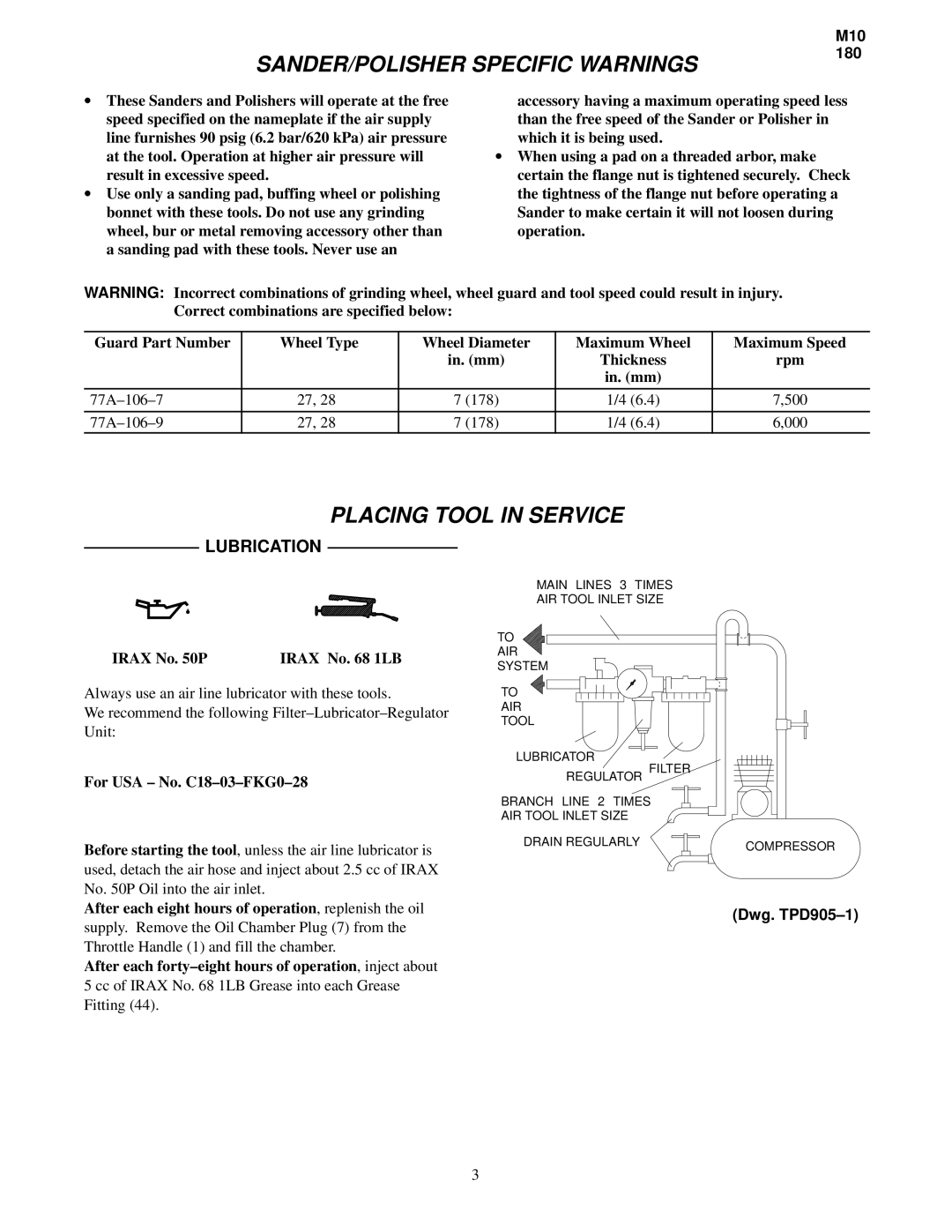

LUBRICATION

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

IRAX No. 50P | IRAX No. 68 1LB |

Always use an air line lubricator with these tools.

We recommend the following

For USA – No. C18–03–FKG0–28

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

FILTER

Before starting the tool, unless the air line lubricator is used, detach the air hose and inject about 2.5 cc of IRAX No. 50P Oil into the air inlet.

After each eight hours of operation, replenish the oil supply. Remove the Oil Chamber Plug (7) from the Throttle Handle (1) and fill the chamber.

After each

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY | COMPRESSOR |

|

(Dwg.

3