Load Chain Reports

Records should be maintained documenting the condition of load chain removed from service as part of a

Frequent Inspection

The Manual Chain Hoist should be inspected at the beginning of each shift. Visual inspections should also be conducted during regular service for any damage or evidence of malfunction which appears between regular inspections.

1.OPERATION. Check for visual signs or abnormal noises which could indicate a potential problem. Do not operate a hoist unless the chain feeds through the hoist and hook block smoothly. Listen for “clicking”, binding or malfunctioning. The clicking sound of the pawl on the ratchet gear is normal when a load is being raised. If chain binds, jumps, or is excessively noisy, clean and lubricate the chain. If problem persists, replace the chain. Do not operate the hoist until all problems have been corrected. Check that hand chain moves freely and without binding or excessive drag. Hook should stop moving when hand chain stops moving.

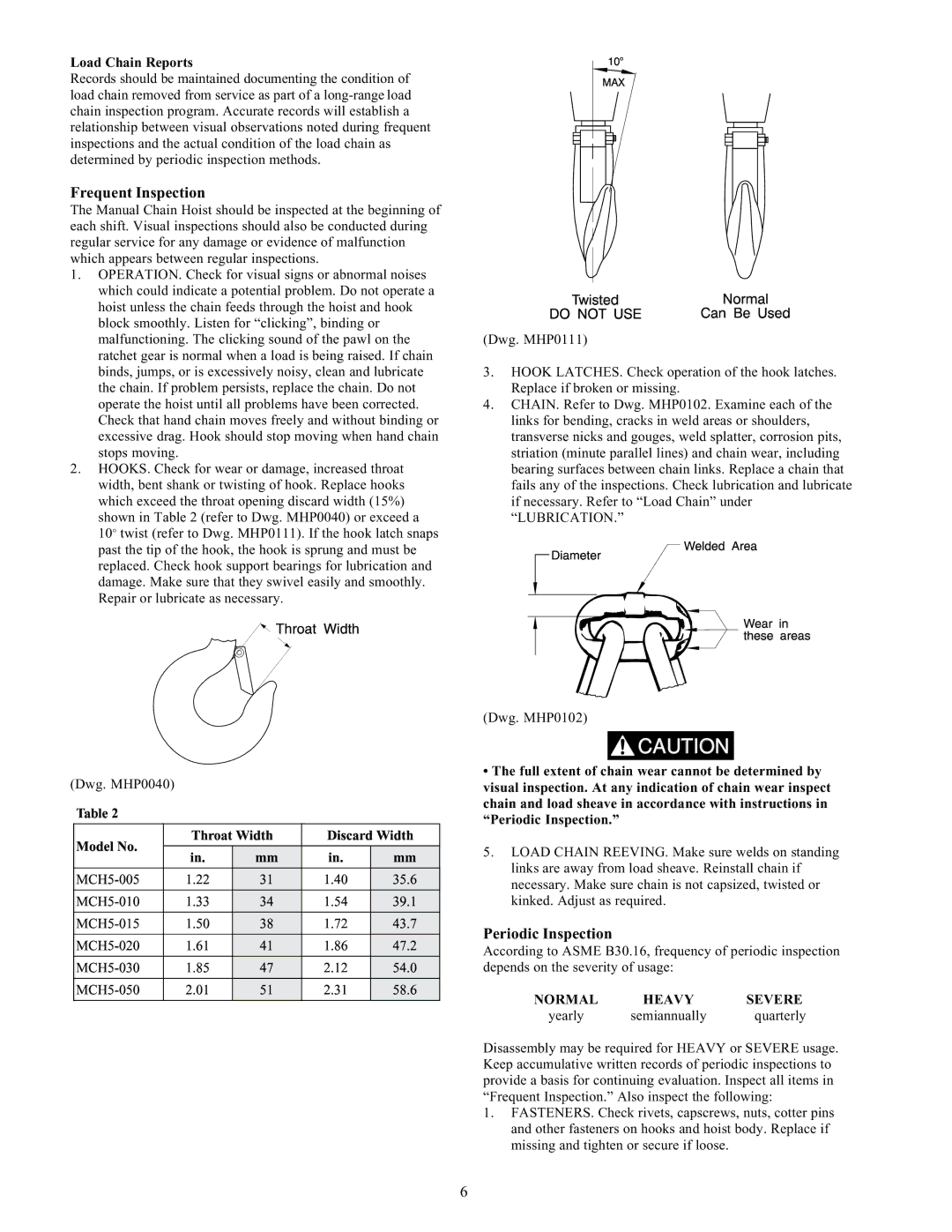

2.HOOKS. Check for wear or damage, increased throat width, bent shank or twisting of hook. Replace hooks which exceed the throat opening discard width (15%) shown in Table 2 (refer to Dwg. MHP0040) or exceed a

10° twist (refer to Dwg. MHP0111). If the hook latch snaps past the tip of the hook, the hook is sprung and must be replaced. Check hook support bearings for lubrication and damage. Make sure that they swivel easily and smoothly. Repair or lubricate as necessary.

(Dwg. MHP0040)

(Dwg. MHP0111)

3.HOOK LATCHES. Check operation of the hook latches. Replace if broken or missing.

4.CHAIN. Refer to Dwg. MHP0102. Examine each of the links for bending, cracks in weld areas or shoulders, transverse nicks and gouges, weld splatter, corrosion pits, striation (minute parallel lines) and chain wear, including bearing surfaces between chain links. Replace a chain that fails any of the inspections. Check lubrication and lubricate if necessary. Refer to “Load Chain” under “LUBRICATION.”

(Dwg. MHP0102)

![]()

![]() CAUTION

CAUTION

•The full extent of chain wear cannot be determined by visual inspection. At any indication of chain wear inspect chain and load sheave in accordance with instructions in “Periodic Inspection.”

5.LOAD CHAIN REEVING. Make sure welds on standing links are away from load sheave. Reinstall chain if necessary. Make sure chain is not capsized, twisted or kinked. Adjust as required.

Periodic Inspection

According to ASME B30.16, frequency of periodic inspection depends on the severity of usage:

NORMAL | HEAVY | SEVERE |

yearly | semiannually | quarterly |

Disassembly may be required for HEAVY or SEVERE usage. Keep accumulative written records of periodic inspections to provide a basis for continuing evaluation. Inspect all items in “Frequent Inspection.” Also inspect the following:

1.FASTENERS. Check rivets, capscrews, nuts, cotter pins and other fasteners on hooks and hoist body. Replace if missing and tighten or secure if loose.

6