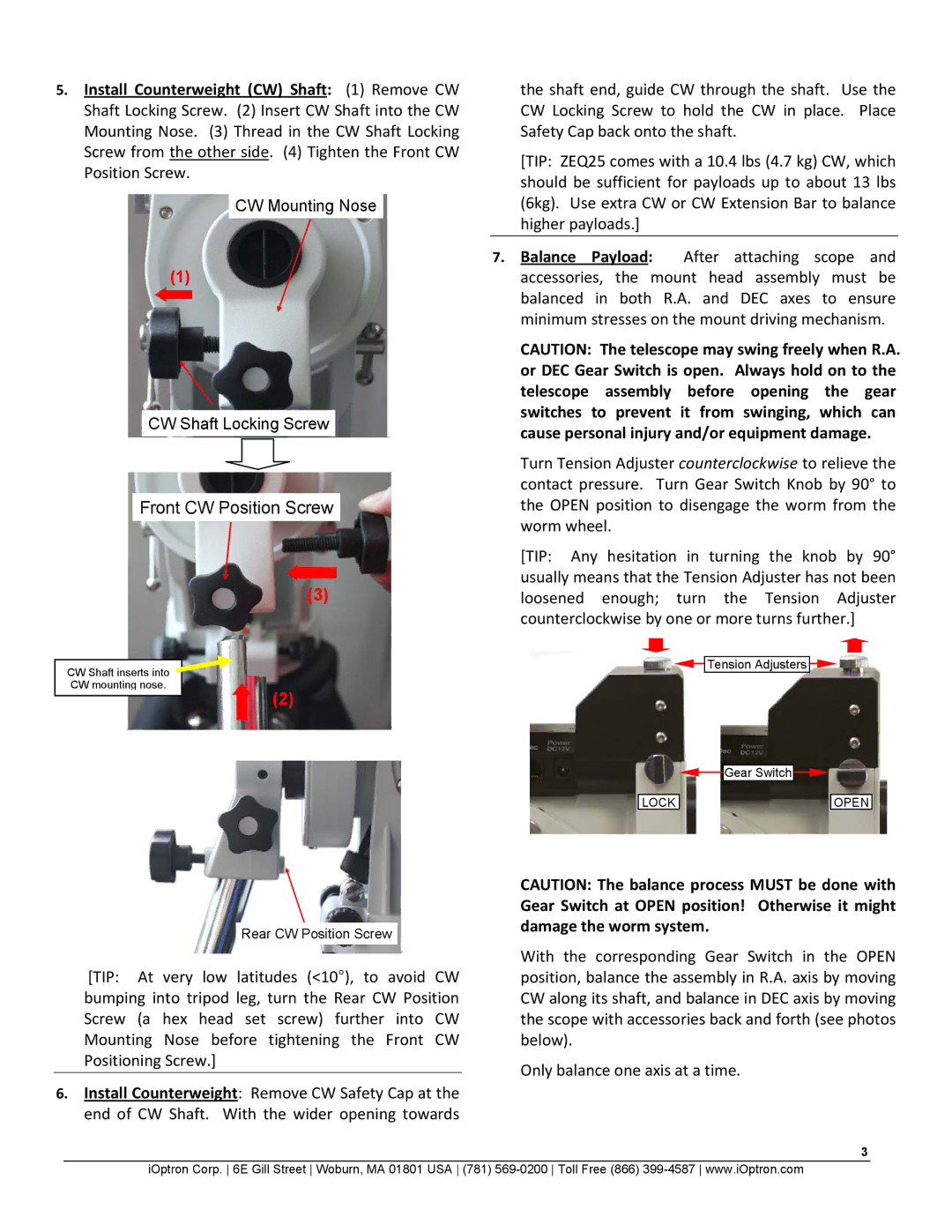

5.Install Counterweight (CW) Shaft: (1) Remove CW Shaft Locking Screw. (2) Insert CW Shaft into the CW Mounting Nose. (3) Thread in the CW Shaft Locking Screw from the other side. (4) Tighten the Front CW Position Screw.

CW Mounting Nose

(1)

CW Shaft Locking Screw

Front CW Position Screw

(3)

CW Shaft inserts into ![]()

CW mounting nose.

(2)

the shaft end, guide CW through the shaft. Use the CW Locking Screw to hold the CW in place. Place Safety Cap back onto the shaft.

[TIP: ZEQ25 comes with a 10.4 lbs (4.7 kg) CW, which should be sufficient for payloads up to about 13 lbs (6kg). Use extra CW or CW Extension Bar to balance higher payloads.]

7.Balance Payload: After attaching scope and accessories, the mount head assembly must be balanced in both R.A. and DEC axes to ensure minimum stresses on the mount driving mechanism.

CAUTION: The telescope may swing freely when R.A. or DEC Gear Switch is open. Always hold on to the telescope assembly before opening the gear switches to prevent it from swinging, which can cause personal injury and/or equipment damage.

Turn Tension Adjuster counterclockwise to relieve the contact pressure. Turn Gear Switch Knob by 90° to the OPEN position to disengage the worm from the worm wheel.

[TIP: Any hesitation in turning the knob by 90° usually means that the Tension Adjuster has not been loosened enough; turn the Tension Adjuster counterclockwise by one or more turns further.]

![]()

![]() Tension Adjusters

Tension Adjusters ![]()

![]()

![]()

![]() Gear Switch

Gear Switch![]()

![]()

LOCK |

| OPEN |

Rear CW Position Screw

[TIP: At very low latitudes (<10°), to avoid CW bumping into tripod leg, turn the Rear CW Position Screw (a hex head set screw) further into CW Mounting Nose before tightening the Front CW Positioning Screw.]

6.Install Counterweight: Remove CW Safety Cap at the end of CW Shaft. With the wider opening towards

CAUTION: The balance process MUST be done with Gear Switch at OPEN position! Otherwise it might damage the worm system.

With the corresponding Gear Switch in the OPEN position, balance the assembly in R.A. axis by moving CW along its shaft, and balance in DEC axis by moving the scope with accessories back and forth (see photos below).

Only balance one axis at a time.

3

iOptron Corp. 6E Gill Street Woburn, MA 01801 USA (781)