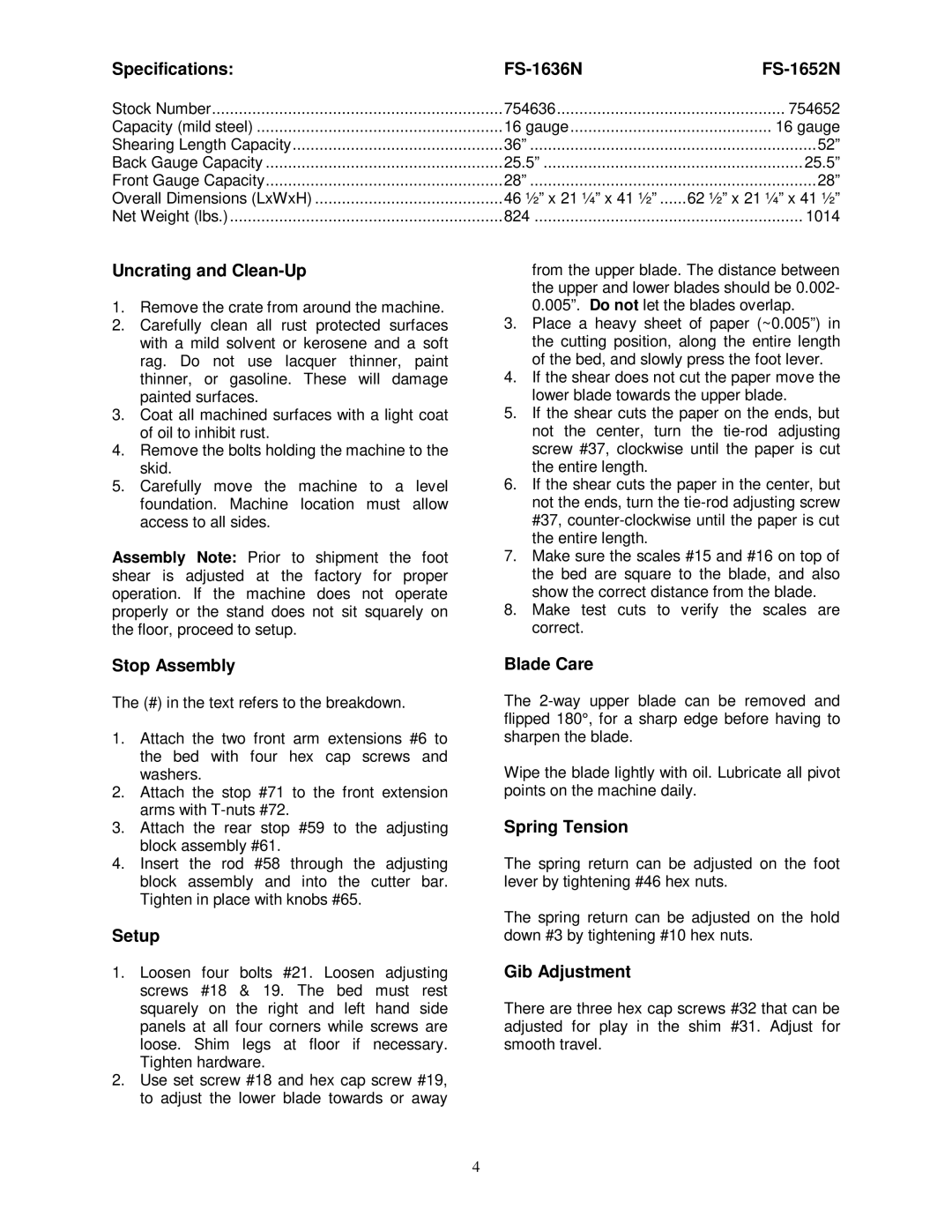

FS-1636N, FS-1652N specifications

The Jet Tools FS-1652N and FS-1636N are two exceptional machines tailored for woodworkers and metalworkers seeking precision and efficiency in their projects. Both models are designed to provide reliable performance, featuring robust construction and advanced technologies that enhance usability and accuracy.The FS-1652N model boasts a large 16" by 52" cast iron table, providing ample workspace for various woodworking tasks. This substantial surface area is essential for handling larger workpieces, allowing for precise cuts and seamless operations. Its heavy-duty frame ensures stability, minimizing vibrations during use, which is crucial for achieving detailed results.

On the other hand, the FS-1636N offers a slightly smaller table at 16" by 36", making it more suitable for smaller shops or projects where space is at a premium. Despite its compact size, the FS-1636N does not compromise on features or capabilities. It shares the same high-quality construction and stability as its larger counterpart, making it an excellent option for professional woodworkers and hobbyists alike.

One of the main technological advancements featured in both models is the innovative digital readout system. This system provides real-time information regarding the position of the blade, ensuring accuracy in every cut. Users can quickly make adjustments, leading to enhanced efficiency and reducing the likelihood of errors in measurement.

Additionally, these machines include a user-friendly controls layout, allowing operators to easily access vital functions without distractions. The intuitive design promotes a safer working environment, as users can focus on their tasks rather than struggling with complicated controls.

Both the FS-1652N and FS-1636N are equipped with precision-ground gears and high-quality bearings, ensuring a smooth operational experience. The integrated dust collection ports also play a crucial role in maintaining a clean workspace, effectively removing debris and minimizing cleanup time after projects.

In summary, the Jet Tools FS-1652N and FS-1636N stand out in the woodworking machinery market due to their durability, precision, and user-friendly features. Whether you're handling intricate designs or large wood panels, these machines cater to diverse needs and guarantee quality results. Their combination of advanced technology and solid construction makes them must-have additions for any serious woodworking workshop.