JML-1014 specifications

The Jet Tools JML-1014 is an exceptional mini lathe designed for woodturning enthusiasts and professionals alike. Its compact design coupled with advanced features ensures both versatility and precision in various woodturning projects. The JML-1014 is engineered for stability and performance, making it an essential addition to any workshop.One of the standout features of the JML-1014 is its robust 1 HP motor, which provides ample power for a wide range of turning applications. The motor is capable of variable speed control, allowing users to adjust the speed from 60 to 3,600 RPM. This wide speed range is ideal for handling different wood types and sizes, ensuring optimal results whether turning delicate items or larger projects.

The lathe is constructed with a heavy-duty cast iron base, which offers exceptional stability during operation. This ensures minimal vibration, allowing for smoother finishes and more precise cuts. The bed is also designed for durability and longevity, with a sleek finish that reduces friction during use.

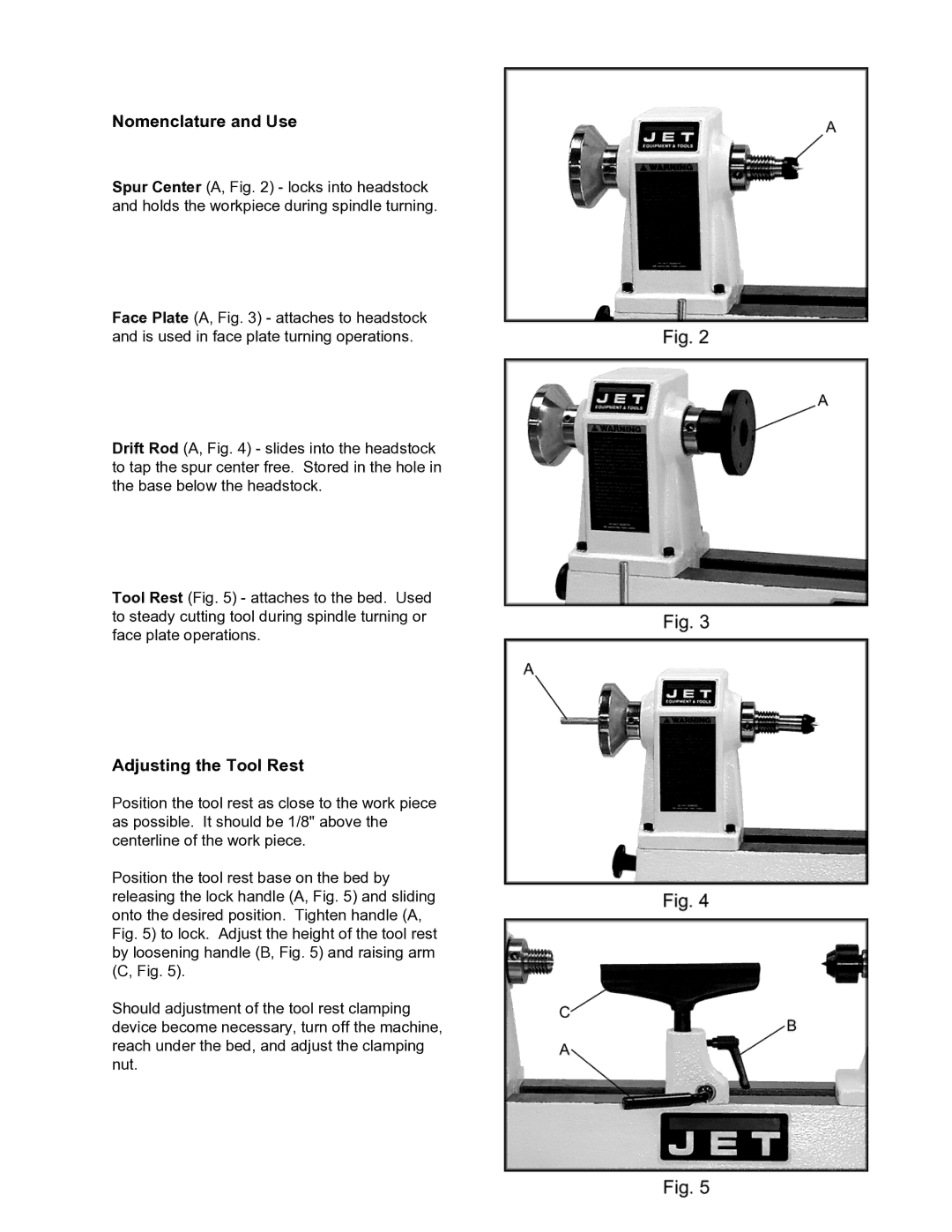

In terms of user-friendliness, the JML-1014 features a swing of 10 inches over the bed and a 14-inch maximum turning length, making it suitable for a variety of workpieces. The lathe is equipped with a digital RPM readout, which helps woodworkers monitor their speed for improved control. Additionally, the integrated tool rest and tailstock are designed for easy adjustments, facilitating seamless switching between different turning techniques.

Another key characteristic of the JML-1014 is its ease of setup and operation. The lathe comes with a user-friendly interface and clear instructions, making it accessible for beginners while still meeting the demands of experienced users. The adjustable tailstock features a quill that can be easily extended for drilling or other operations, enhancing the functionality of the machine.

Jet Tools has also incorporated safety features into the JML-1014, including a quick-release tailstock lever and a large off switch for convenience and peace of mind. These safety measures ensure that users can focus on their craft without worrying about accidents.

Overall, the Jet Tools JML-1014 is a well-engineered mini lathe that combines power, precision, and user-friendly features. Its robust construction and versatile capabilities make it a standout choice for woodturners looking to elevate their creations. Whether you're a seasoned professional or just starting, the JML-1014 is designed to empower your creativity and craftsmanship in the world of woodturning.