Adjusting 90 Degree Table Stop

1.Blade tension must be properly adjusted prior to adjusting 90 degree stop, see “Adjusting Blade Tension” page 13.

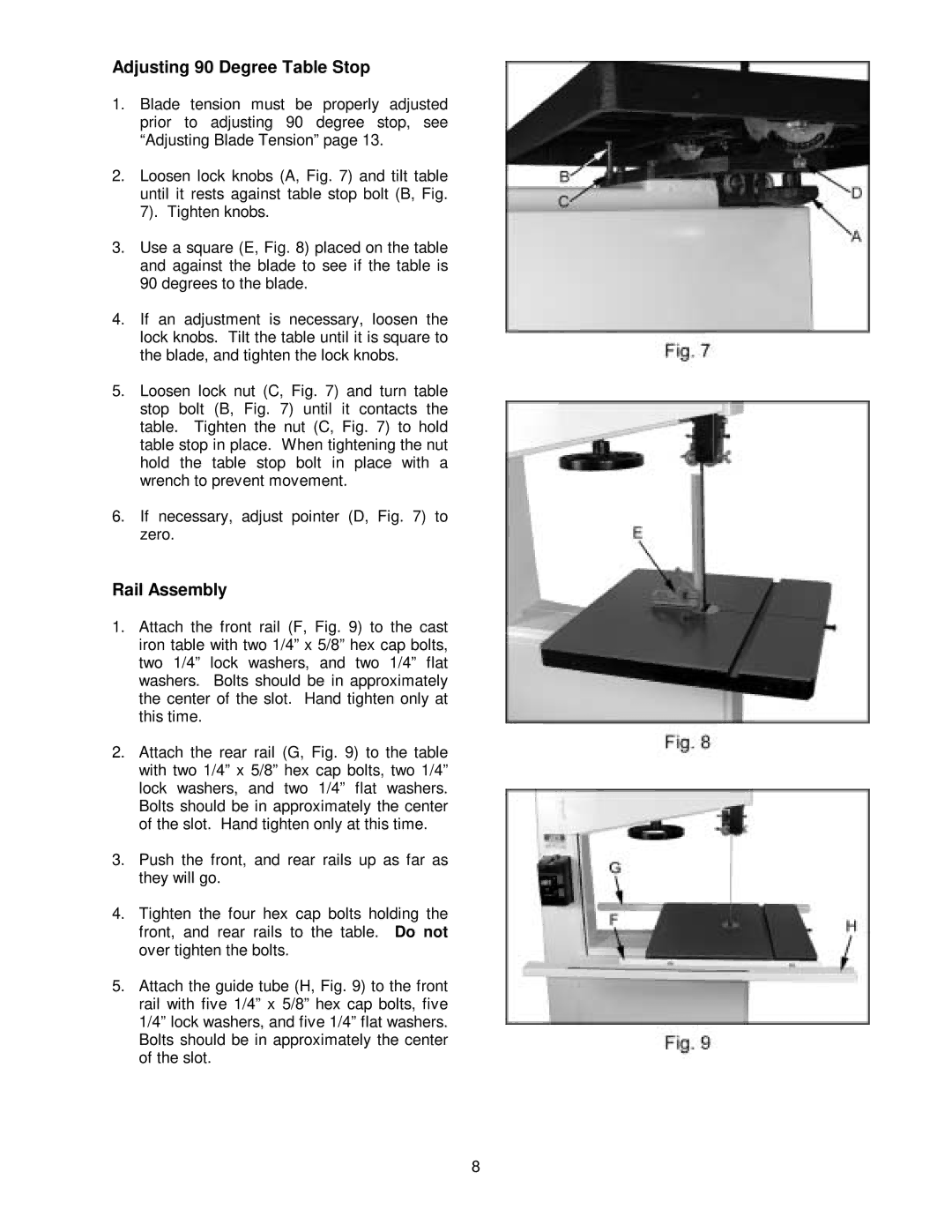

2.Loosen lock knobs (A, Fig. 7) and tilt table until it rests against table stop bolt (B, Fig. 7). Tighten knobs.

3.Use a square (E, Fig. 8) placed on the table and against the blade to see if the table is 90 degrees to the blade.

4.If an adjustment is necessary, loosen the lock knobs. Tilt the table until it is square to the blade, and tighten the lock knobs.

5.Loosen lock nut (C, Fig. 7) and turn table stop bolt (B, Fig. 7) until it contacts the table. Tighten the nut (C, Fig. 7) to hold table stop in place. When tightening the nut hold the table stop bolt in place with a wrench to prevent movement.

6.If necessary, adjust pointer (D, Fig. 7) to zero.

Rail Assembly

1.Attach the front rail (F, Fig. 9) to the cast iron table with two 1/4” x 5/8” hex cap bolts, two 1/4” lock washers, and two 1/4” flat washers. Bolts should be in approximately the center of the slot. Hand tighten only at this time.

2.Attach the rear rail (G, Fig. 9) to the table with two 1/4” x 5/8” hex cap bolts, two 1/4” lock washers, and two 1/4” flat washers. Bolts should be in approximately the center of the slot. Hand tighten only at this time.

3.Push the front, and rear rails up as far as they will go.

4.Tighten the four hex cap bolts holding the front, and rear rails to the table. Do not over tighten the bolts.

5.Attach the guide tube (H, Fig. 9) to the front rail with five 1/4” x 5/8” hex cap bolts, five 1/4” lock washers, and five 1/4” flat washers. Bolts should be in approximately the center of the slot.

8