Sanding Disc Replacement

1.Disconnect machine from the power source.

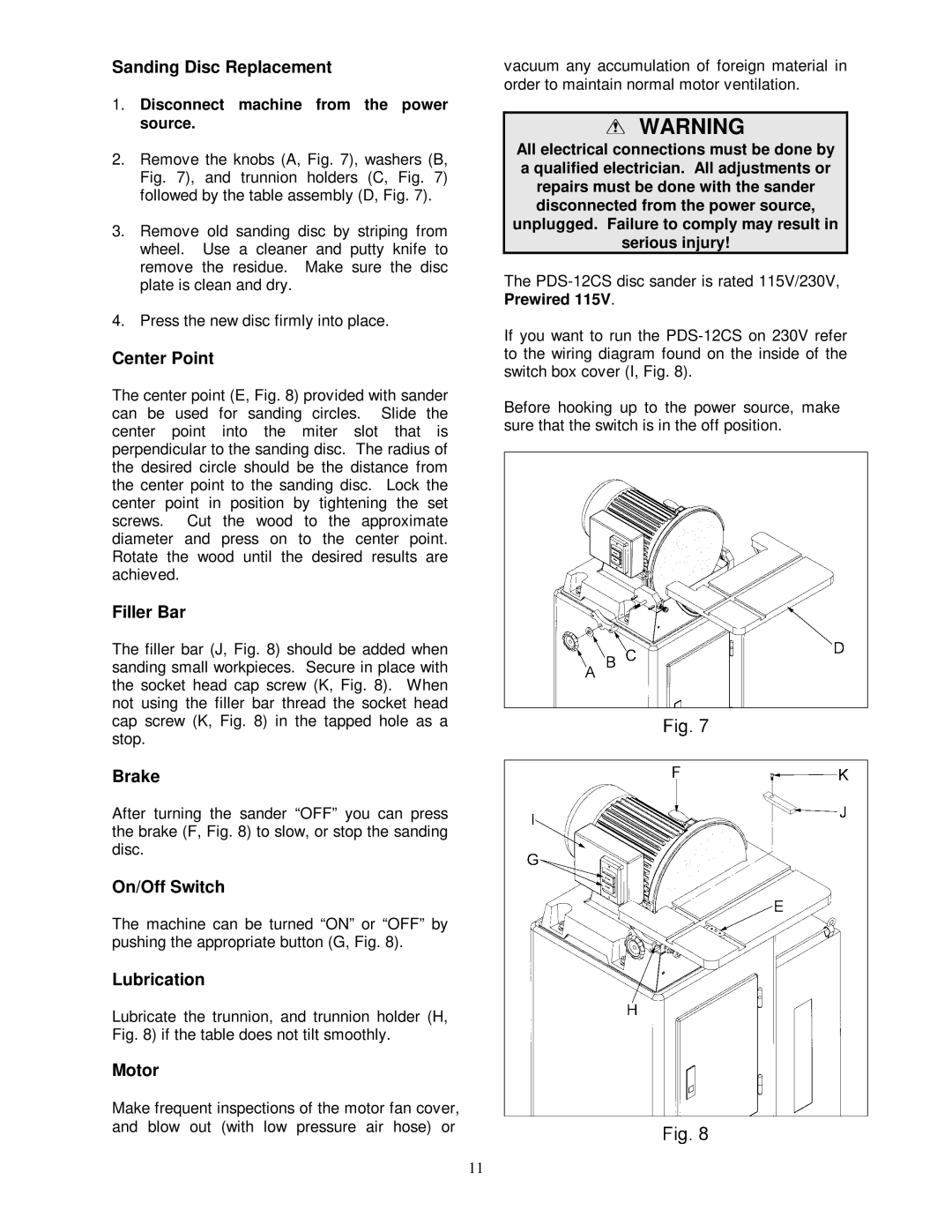

2.Remove the knobs (A, Fig. 7), washers (B, Fig. 7), and trunnion holders (C, Fig. 7) followed by the table assembly (D, Fig. 7).

3.Remove old sanding disc by striping from wheel. Use a cleaner and putty knife to remove the residue. Make sure the disc plate is clean and dry.

4.Press the new disc firmly into place.

Center Point

The center point (E, Fig. 8) provided with sander can be used for sanding circles. Slide the center point into the miter slot that is perpendicular to the sanding disc. The radius of the desired circle should be the distance from the center point to the sanding disc. Lock the center point in position by tightening the set screws. Cut the wood to the approximate diameter and press on to the center point. Rotate the wood until the desired results are achieved.

Filler Bar

The filler bar (J, Fig. 8) should be added when sanding small workpieces. Secure in place with the socket head cap screw (K, Fig. 8). When not using the filler bar thread the socket head cap screw (K, Fig. 8) in the tapped hole as a stop.

Brake

After turning the sander “OFF” you can press the brake (F, Fig. 8) to slow, or stop the sanding disc.

On/Off Switch

The machine can be turned “ON” or “OFF” by pushing the appropriate button (G, Fig. 8).

Lubrication

Lubricate the trunnion, and trunnion holder (H, Fig. 8) if the table does not tilt smoothly.

Motor

Make frequent inspections of the motor fan cover, and blow out (with low pressure air hose) or

vacuum any accumulation of foreign material in order to maintain normal motor ventilation.

WARNING

All electrical connections must be done by a qualified electrician. All adjustments or repairs must be done with the sander disconnected from the power source, unplugged. Failure to comply may result in serious injury!

The

Prewired 115V.

If you want to run the

Before hooking up to the power source, make sure that the switch is in the off position.

11