PRODUCT DESCRIPTION

The JL Audio e1800D is a monoblock subwoofer amplifier utilizing proprietary and patented Class D technology. Its frequency response is limited to the range below 250 Hz. It is not designed

for driving midrange speakers or tweeters. Every aspect of its operation has been optimized for low-frequency amplification. For detailed specifications, please refer to Appendix C (page 11).

TYPICAL INSTALLATION SEQUENCE

The following represents the sequence for a typical amplifier installation, using an aftermarket source unit. Additional steps and different procedures may be required in some applications. If you have any questions, please contact your authorized JL Audio dealer for assistance.

1)Disconnect the negative battery post connection and secure the disconnected cable to prevent accidental re-connection during installation.

This step is not optional!

2)Run power wire (minimum 4 AWG) from the battery location to the amplifier mounting location, taking care to route it in such a way that it will not be damaged and will not interfere with vehicle operation. Use 2 AWG or 1/0 AWG power wire if additional amplifiers are being installed with the e1800D.

3)Connect power wire to the positive battery post. Fuse the wire with an appropriate fuse block (and connectors) within 18 inches (45 cm) wire length of the positive battery post. This fuse is essential to protect the vehicle. Do not install the fuse until the power wire has been connected to the amplifier.

4)Run signal cables and remote turn-on wire from the source unit to the amplifier mounting location.

5)Run speaker wire from the speaker system to the amplifier mounting location.

6)Find a good, solid metal grounding point

close to the amplifier and connect the negative power wire to it using appropriate hardware. Use the same size power wire as the wire connected to the “+12V” connection (min. 4 AWG), no longer than 36 inches (90 cm) from the amplifier to the ground connection point. In some vehicles, it may

be necessary to upgrade the battery ground wire. (See page 5 for important notice).

7)Securely mount the amplifier using the supplied screws.

8)Connect the positive and negative power wires to the amplifier. A fuse near the amplifier is not necessary.

9)Connect the remote turn-on wire to

the amplifier.

10)Connect the input cables to the amplifier.

11)Connect the speaker wires to the amplifier.

12)Carefully review the amplifier’s control settings to make sure that they are set according to the needs of the system.

13)Install power wire fuse (80A for a

single e1800D) and reconnect the negative battery post terminal.

14)Turn on the source unit at a low level to double-check that the amplifier is configured correctly. Resist the temptation to crank it up until you have verified the control settings.

15)Make necessary adjustments to the input sensitivity controls to obtain the right overall output and the desired balance in the system. See Appendix A (page 10) for the recommended input sensitivity setting method.

16)Enjoy the fruits of your labor with your favorite music.

POWER CONNECTIONS

Before installing the amplifier, disconnect the negative (ground) wire from the vehicle's battery. This will prevent accidental damage to the system, the vehicle and your body during installation.

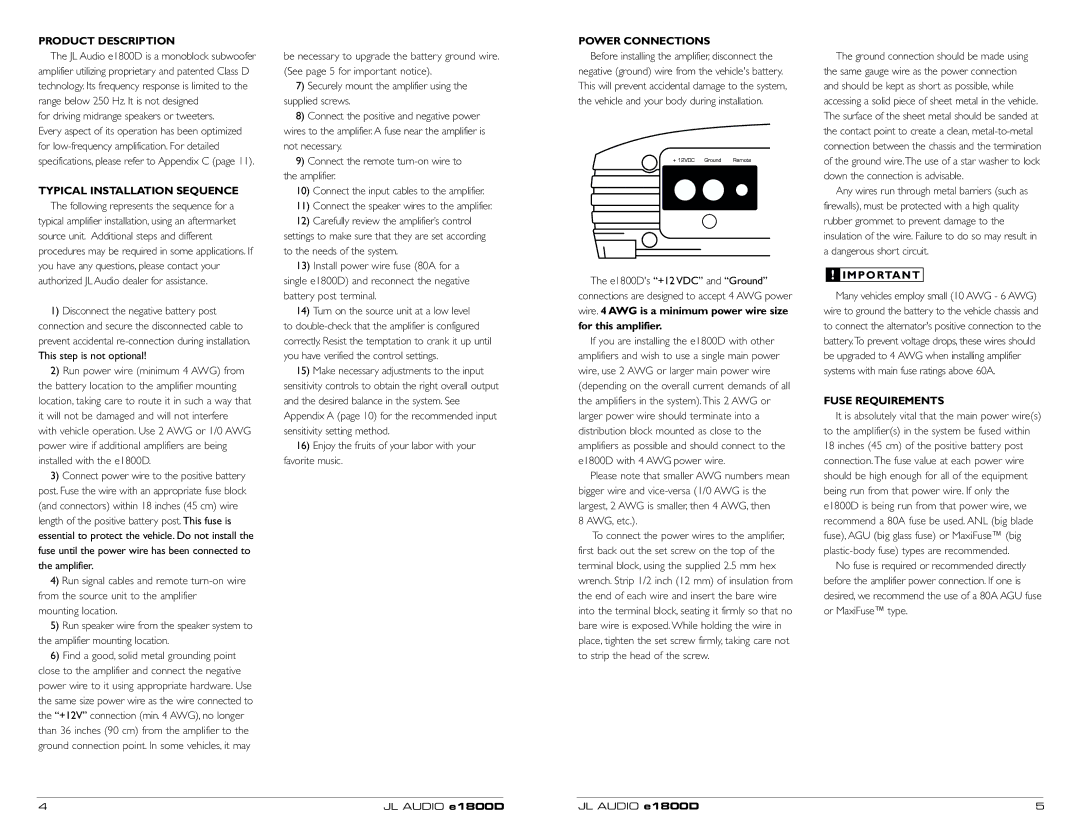

The e1800D's “+12 VDC” and “Ground” connections are designed to accept 4 AWG power wire. 4 AWG is a minimum power wire size

for this amplifier.

If you are installing the e1800D with other amplifiers and wish to use a single main power wire, use 2 AWG or larger main power wire (depending on the overall current demands of all the amplifiers in the system).This 2 AWG or larger power wire should terminate into a distribution block mounted as close to the amplifiers as possible and should connect to the e1800D with 4 AWG power wire.

Please note that smaller AWG numbers mean bigger wire and vice-versa (1/0 AWG is the largest, 2 AWG is smaller, then 4 AWG, then

8 AWG, etc.).

To connect the power wires to the amplifier, first back out the set screw on the top of the terminal block, using the supplied 2.5 mm hex wrench. Strip 1/2 inch (12 mm) of insulation from the end of each wire and insert the bare wire into the terminal block, seating it firmly so that no bare wire is exposed. While holding the wire in place, tighten the set screw firmly, taking care not to strip the head of the screw.

The ground connection should be made using the same gauge wire as the power connection and should be kept as short as possible, while accessing a solid piece of sheet metal in the vehicle. The surface of the sheet metal should be sanded at the contact point to create a clean, metal-to-metal connection between the chassis and the termination of the ground wire.The use of a star washer to lock down the connection is advisable.

Any wires run through metal barriers (such as firewalls), must be protected with a high quality rubber grommet to prevent damage to the insulation of the wire. Failure to do so may result in a dangerous short circuit.

! IMPORTANT

IMPORTANT

Many vehicles employ small (10 AWG - 6 AWG) wire to ground the battery to the vehicle chassis and to connect the alternator's positive connection to the battery.To prevent voltage drops, these wires should be upgraded to 4 AWG when installing amplifier systems with main fuse ratings above 60A.

FUSE REQUIREMENTS

It is absolutely vital that the main power wire(s) to the amplifier(s) in the system be fused within 18 inches (45 cm) of the positive battery post connection.The fuse value at each power wire should be high enough for all of the equipment being run from that power wire. If only the e1800D is being run from that power wire, we recommend a 80A fuse be used. ANL (big blade fuse), AGU (big glass fuse) or MaxiFuse™ (big plastic-body fuse) types are recommended.

No fuse is required or recommended directly before the amplifier power connection. If one is desired, we recommend the use of a 80A AGU fuse or MaxiFuse™ type.