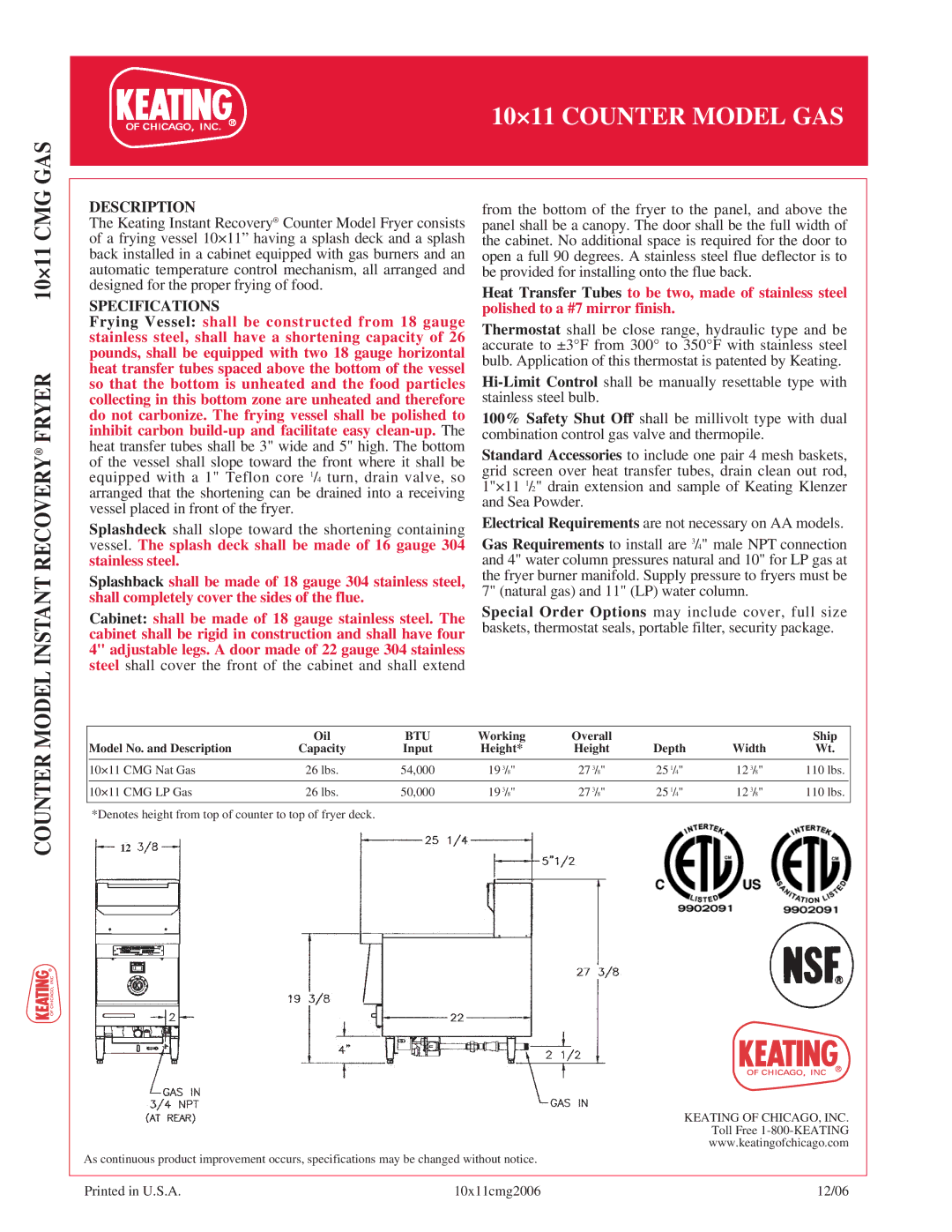

1011 specifications

Keating of Chicago 1011 is a remarkable commercial kitchen appliance designed specifically for high-efficiency cooking. As the demands of the culinary industry continue to evolve, this equipment brings innovative solutions that cater to both speed and quality, making it popular among chefs and restaurant operators.One of the main features of Keating 1011 is its unique cooking technology that combines radiant heat and convection, enabling food to cook evenly and quickly. This dual-function technology not only enhances the taste and texture of the dishes but also saves energy, thereby reducing operational costs. The unit achieves rapid temperature recovery, which is essential during peak cooking times, ensuring that chefs can maintain consistent quality without delays.

The design of the Keating 1011 reflects a focus on durability and user-friendliness. Built with stainless steel, it guarantees resilience against the rigors of a busy kitchen environment while also making cleaning and maintenance effortless. The control panel is intuitively designed, allowing culinary professionals to adjust settings with simplicity, minimizing the learning curve for new staff.

Safety is paramount in kitchen environments, and the Keating 1011 incorporates several safety features. These include automatic shut-off systems that activate in case of overheating, ensuring that kitchen personnel can work with peace of mind. Additionally, the appliance is designed to minimize the risk of burns, as the exterior remains cool to the touch during operation.

Moreover, the versatility of the Keating 1011 cannot be overstated. It is suitable for a wide range of cooking processes, from frying and grilling to sautéing. This adaptability makes it an invaluable asset for various culinary styles, allowing chefs to experiment and innovate without needing multiple specialized appliances.

With its advanced technology, robust construction, and safety features, the Keating of Chicago 1011 stands out as an exceptional piece of equipment for modern kitchens. Its efficiency and effectiveness cater to the rigorous demands of the food service industry, making it an excellent investment for establishments aiming to enhance productivity while maintaining high culinary standards.