Read and understand these instructions thoroughly before installing

beer dispenser.

ASSEMBLY

1.Carton Inventory

Unpack and inspect the parts. Make sure all items are present and in good condition.

1Draft arm assembly (Package includes 1 gasket for draft arm and 1 washer for connection to keg tapper)

1CO2 regulator

1CO2 cylinder

1Keg tapper (Sankey type)

1Cleaning kit

1Pressure tube

2Hose clamps

2Keg supports (wooden plates)

1CO2 cylinder retainer (spring)

1Guard rail

1Drip tray

4Wheel casters

4Hex head screws (5mm dia x 15mm long)

16Machine screws (5mm dia x 12mm long)

8Small screws (5mm dia x 10mm long)

2.Install casters

a.Empty the cabinet and then lay down the beer dispenser sideways so that the door hingeside comes to the top. Be careful not to cause dents or scratches on the cabinet.

Placing outer carton underneath the cabinet is recommended.

b.Install casters to the four bottom corners of the cabinet

with the four machine screws (5mm dia x 12mm long) for each caster.

c.Stand the cabinet upright.

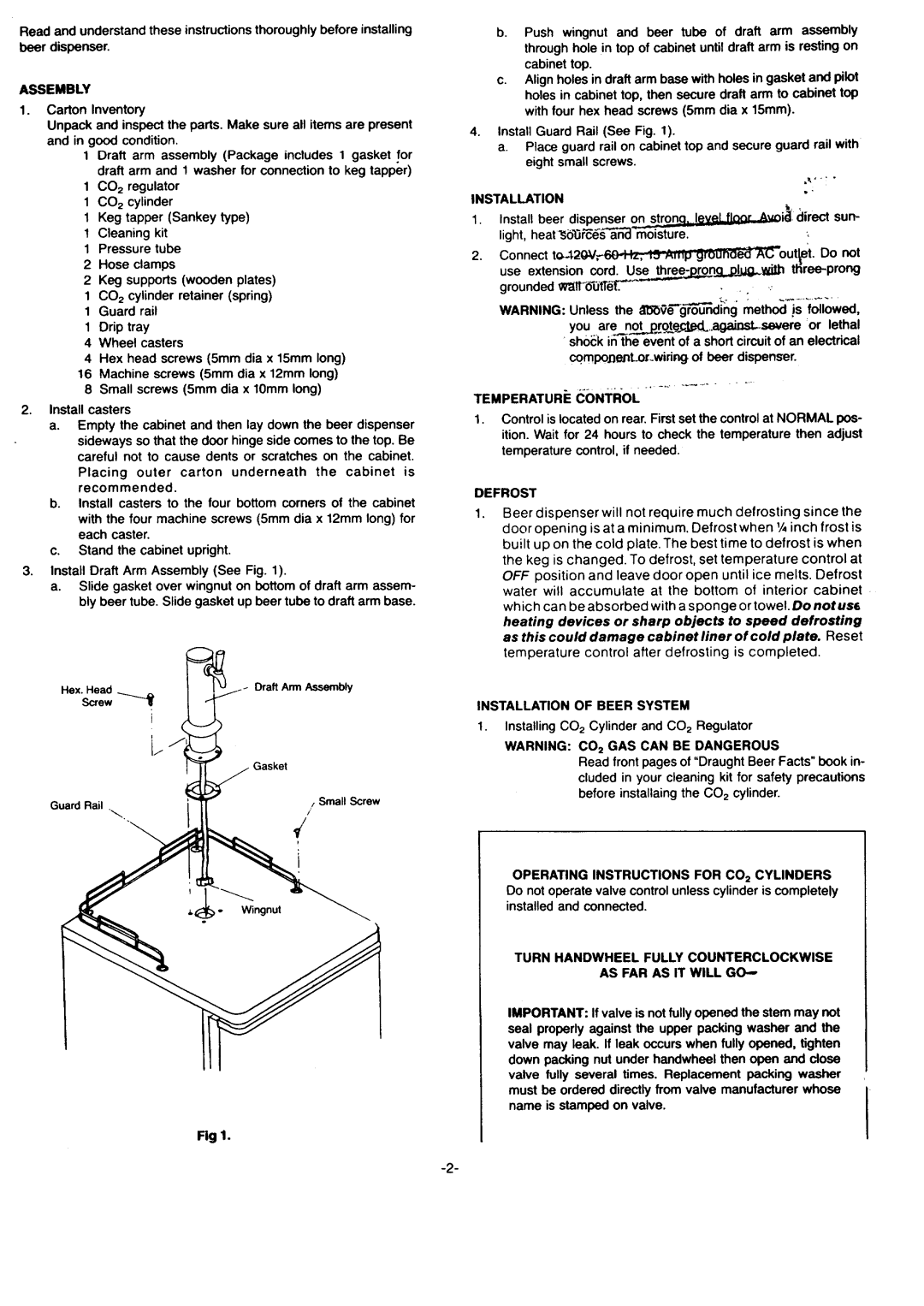

3.Install Draft Arm Assembly (See Fig. 1).

a.Slide gasket over wingnut on bottom of draft arm assem- bly beer tube. Slide gasket up beer tube to draft arm base.

Hex. Head | Draft Arm Assembly |

Screw |

|

| i |

| I |

| Gasket |

Guard Rail .,_ • | / / Small Screw |

b.Push wingnut and beer tube of draft arm assembly through hole in top of cabinet until draft arm is resting on cabinet top.

c.Align holes in draftarm base with holes in gasket and pilot holes in cabinet top, then secure draft arm to cabinet top with four hex head screws (5mm dia x 15mm).

4.Install Guard Rail (See Fig. 1).

a.Place guard rail on cabinet top and secure guard rail with eight small screws.

INSTALLATION"

1.Install beer dispenser on

2. Connect | , |

| out_et. Do not |

use extension cord. Use __q,,_X_tb |

| ||

grounded W'_ff'6"0t1"b.'t | , .. | ,., | |

WARNING: Unless the

you are not

cq.mponer=Lor_widngof beer dispenser.

TEMPERATURE CONTROL

1.Controlis located on rear. Firstset the control at NORMAL pos- ition. Wait for 24 hours to check the temperature then adjust temperature control, if needed.

DEFROST

1.Beer dispenser will not require much defrosting since the door opening is at a minimum. Defrost when V4inch frost is built up on the cold plate. The best time to defrost is when the keg is changed. To defrost, set temperature control at OFF position and leave door open until ice melts. Defrost water will accumulate at the bottom of interior cabinet which can be absorbed with a sponge or towel.Do notus6 heating devices or sharp objects to speed defrosting as this could damage cabinet liner of cold plate. Reset temperature control after defrosting is completed.

INSTALLATION OF BEER SYSTEM

1. InstallingCO 2 Cylinder and CO2 Regulator

WARNING: CO2 GAS CAN BE DANGEROUS

Read front pages of "Draught Beer Facts" book in- cluded in your cleaning kit for safety precautions before installaing the CO2 cylinder.

OPERATING INSTRUCTIONS FOR CO2 CYLINDERS

Do not operate valve control unlesscylinder is completely installedand connected.

TURN HANDWHEEL FULLY COUNTERCLOCKWISE

AS FAR AS IT WILL

IMPORTANT: If valve is not fullyopened the stem may not seal properly against the upper packing washer and the valve may leak. If leak occurswhen fully opened, tighten down packing nut under handwheel then open and close valve fully several times. Replacement packing washer must be ordered directly from valve manufacturer whose name is stamped on valve.

Fig 1.