SECTION 5

SERVICE TECH INFORMATION

|

|

|

|

| 5A. |

|

|

|

| TROUBLESHOOTING |

|

|

|

|

|

|

|

|

|

| |||||||

AUTOMATIC |

| ELECTRONIC |

| DIAGNOSTICS |

| The | chart | below |

| shows the | error | codes | that | could | |||||||||||||

The | faceplate | timer | (PWA) | computer | has | a | self- | appear, | and | the | possible | defects | for | each | code. | ||||||||||||

diagnostic | function | for | the | electrical | system, | ex- | While | an | error | code | appears | in the | display, | all face | |||||||||||||

cept | for | input power | and | water |

|

|

|

| |||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

meter. |

| The | computer | monitors |

|

|

|

|

| plate | buttons | are | inoperable | except | the SELECT | ||||||||||||

|

|

|

|

|

| button. | SELECT | remains | operational | so | the | service | |||||||||||||||

the electronic |

| components | and |

| ] | ||||||||||||||||||||||

circuits | for | correct | operation. | If |

|

|

|

| person | can | make | the | MANUAL | INITIATED | ELEC- | ||||||||||||

|

|

|

| TRONIC | DIAGNOSTICS | (below) | to further | isolate | |||||||||||||||||||

a malfunction |

| occurs, | an error |

|

|

|

| ||||||||||||||||||||

code | appears | in | the | faceplate |

|

|

|

|

| the | defect, |

| and | check | the | water | meter. |

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

display. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| POSSIBLE | DEFECT |

|

|

|

|

|

|

|

|

| ||||

CODE |

|

| MOST LIKELY |

|

|

|

|

|

|

|

|

|

|

|

|

|

| LESS LIKELY | |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Err1 |

|

|

| motor | inoperative | / wiring harness | or connection | to switch | / position | switch | / faceplate | timer | (PWA) | ||||||||||||||

Err3 |

|

|

| motor / faceplate timer | (PWA) |

| See faceplate | timer | (PWA) | replacement |

|

|

|

| |||||||||||||

Err4 |

|

|

| timer (PWA) / position switch |

| on page | 22. |

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

Err5 |

|

|

| faceplate | timer | (PWA) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

PROCEDURE | FOR | REMOVING | ERROR | CODE | FROM | FACEPLATE: |

| 1. Unplug |

| transformer | 2. | Correct | |||||||||||||||

defect | 3. Plug | in | transformer | 4. Wait | for 6 minutes. | The error | code | will return | if the | defect | was | not | corrected. | ||||||||||||||

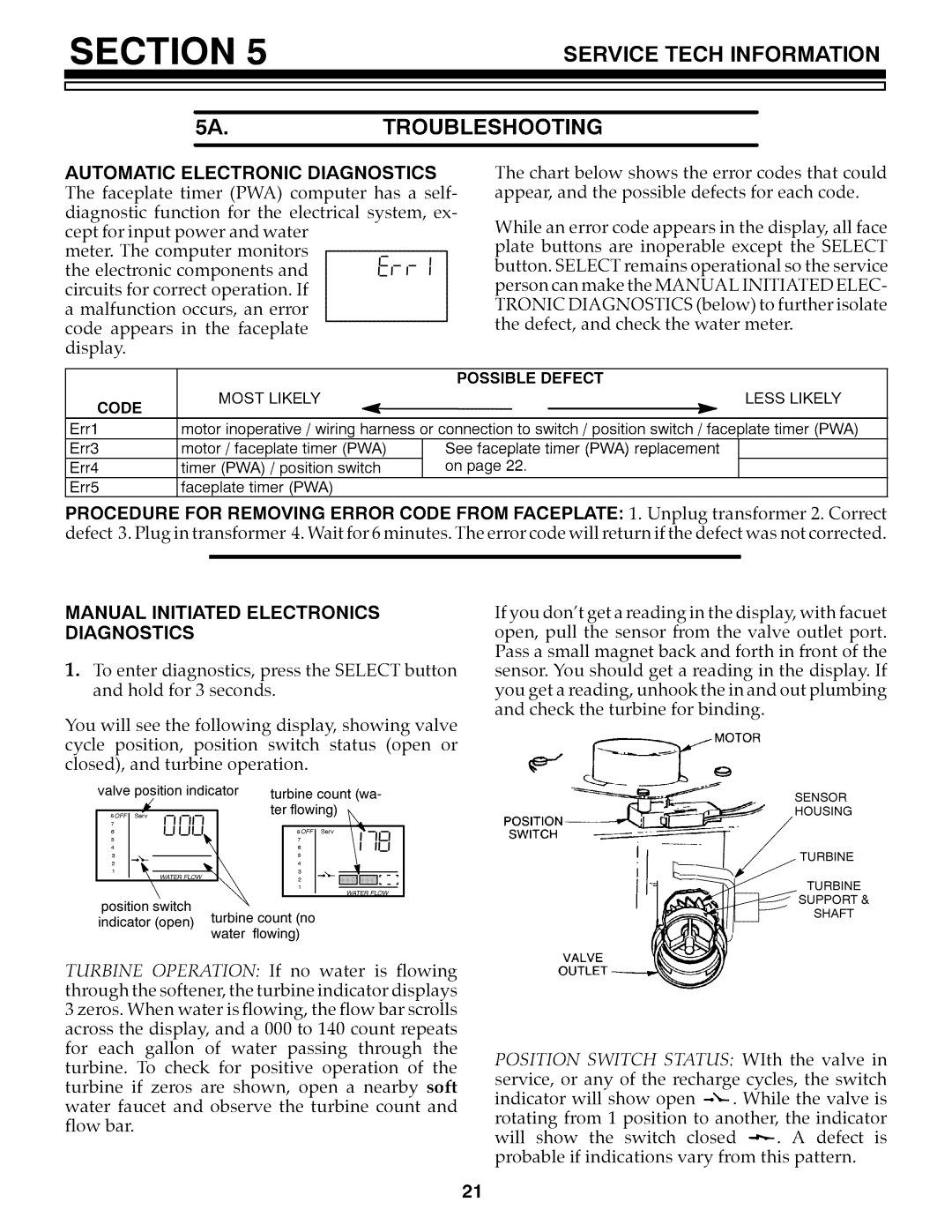

MANUAL INITIATED ELECTRONICS DIAGNOSTICS

1. To enter diagnostics, press the SELECT button and hold for 3 seconds.

You will see the following display, showing valve

cycle position, position switch status (open or

closed), and turbine operation.

valve position indicator turbine count (wa-

....... N NN |

| ter flowing) |

|

|

| ; | l_qo |

|

| i | 1''U |

position switch | turbine | count (no |

|

indicator (open) |

| ||

| water | flowing) |

|

TURBINE OPERATION: If no water is flowing

through the softener, the turbine indicator displays

3 zeros. When water is flowing, the flow bar scrolls across the display, and a 000 to 140 count repeats

for each gallon of water passing through the

turbine. To check for positive operation of the

turbine if zeros are shown, open a nearby soft

water faucet and observe the turbine count and flow bar.

If you don't get a reading in the display, with facuet

open, pull the sensor from the valve outlet port.

Pass a small magnet back and forth in front of the

sensor. You should get a reading in the display. If

you get a reading, unhookthe in and out plumbing

and check the turbine for binding.

MOTOR

SENSOR

HOUSING

POSITION

SWITCH

JRBINE

TURBINE

SHAFT

VALVE

OL

POSITION SWITCH STATUS: With the valve in

service, or any of the recharge cycles, the switch

indicator will show open

rotating from 1 position to another, the indicator

will show the switch closed

probable if indications vary from this pattern.

21