- CARE OF YOUR REVERSE OSMOSIS SYSTEM -

2.Press inward while turning the RO cap to the left

(_) to remove from the bracket/membrane housing.

3.Use a pliers, or heavy wire made into a hook, to

pull the RO cartridge from the housing.

Note: Sanitizing is recommended after servicing in- ner parts of the system (see page 9).

4. Install the new cartridge, end with

of cartridge about

5.Lubricate the RO cap o- ring seal if dry. Replace the

if the RO cartridge is not fully seated inward.

6.Check the flow control and screen (see below).

7.Purge the RO membrane cartridge following instruc- tions on page 9.

5.Inspect the

or otherwise damaged. Carefully replace into the drain port.

6.Be sure the flow control is in the end of the tubing, then push all the way into the fitting.

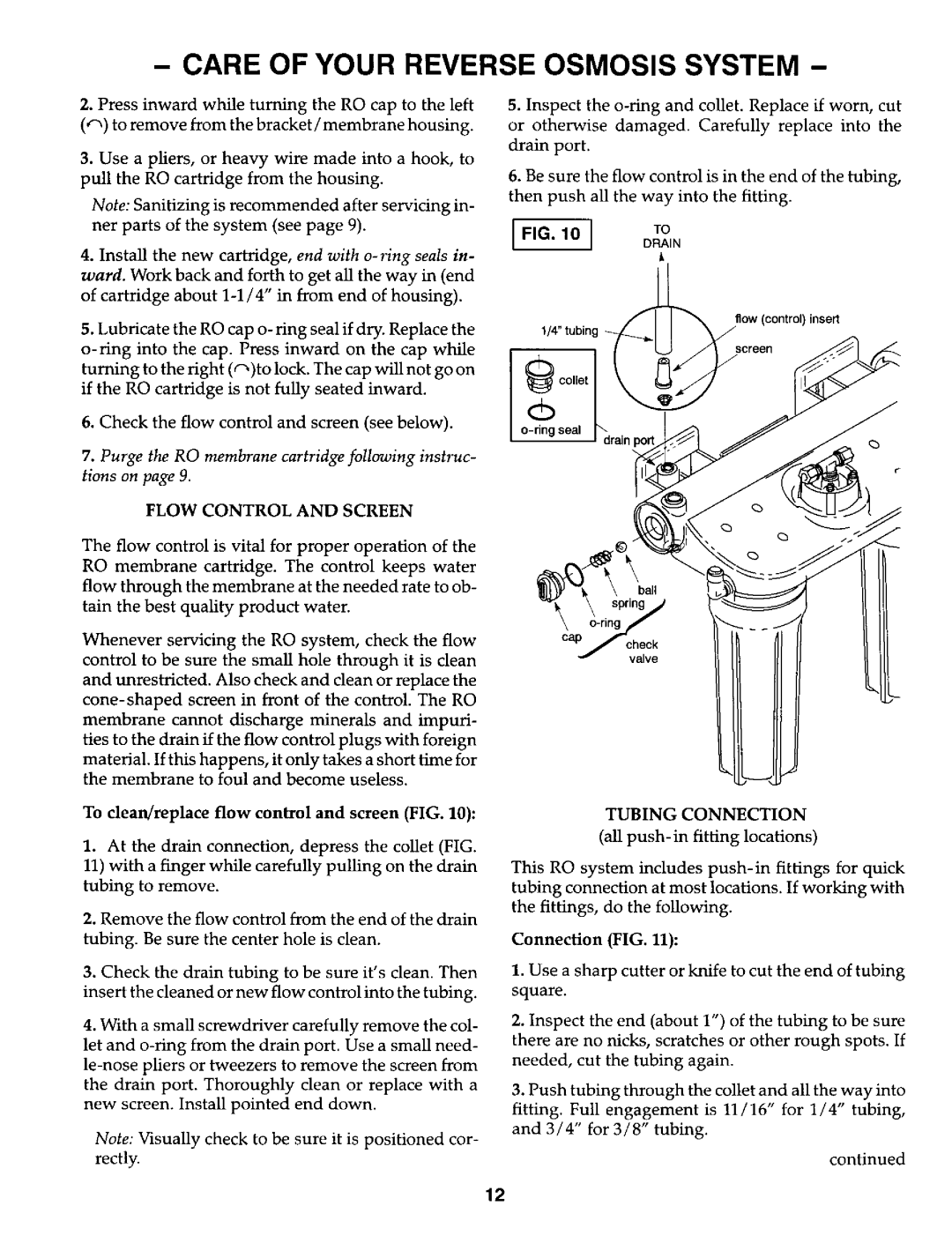

FIG. 10 ] | TO |

| DRAIN |

| A |

flow (control) insert

l/4"tubi, ng _"1 | ] | _screen |

FLOW CONTROL AND SCREEN

The flow control is vital for proper operation of the

RO membrane cartridge. The control keeps water

flow through the membrane at the needed rate to ob-

tain the best quality product water.

Whenever servicing the RO system, check the flow

control to be sure the small hole through it is clean

and unrestricted. Also check and clean or replace the

membrane cannot discharge minerals and impuri- ties to the drain if the flow control plugs with foreign

material. If this happens, it only takes a short time for

the membrane to foul and become useless.

To clean/replace flow control and screen (FIG. 10):

1.At the drain connection, depress the collet (FIG.

11)with a finger while carefully pulling on the drain tubing to remove.

2.Remove the flow control from the end of the drain tubing. Be sure the center hole is clean.

3.Check the drain tubing to be sure it's clean. Then insert the cleaned or new flow control into the tubing.

4.With a small screwdriver carefully remove the col- let and

the drain port. Thoroughly clean or replace with a

new screen. Install pointed end down.

Note: Visually check to be sure it is positioned cor- rectly.

ball

spring_

cap _check

,i valve

TUBING CONNECTION

(all

This RO system includes

tubing connection at most locations. If working with the fittings, do the following.

Connection (FIG. 11):

1.Use a sharp cutter or knife to cut the end of tubing square.

2.Inspect the end (about 1") of the tubing to be sure

there are no nicks, scratches or other rough spots. If

needed, cut the tubing again.

3.Push tubing through the collet and all the way into

fitting. Full engagement is 11/16" for 1/4" tubing, and 3/4" for 3/8" tubing.

continued

12