PROCESSING

Process this film in Process

Because there is no

The antihalation dyes used in VISION Premier Color Print Film are decolorized and removed during processing. Although most of the dye is removed in the developer, complete removal is also dependent on the “tail end” solutions, such as the bleach.

To prevent static during projection, maintain a relative humidity of 50 to 60 percent in the projection room.

It is important that you maintain a “clean” process: proper solution mix and storage procedures to minimize “tar” formation, process machine and recirculation designed to minimize aeration (e.g., submerged racks), periodic cleaning of racks and tanks, proper maintenance of squeegees and wiper blades, and efficient filtration.

For more information, see KODAK Publication No.

LABORATORY AIM DENSITY (LAD) CONTROL METHOD

To control your process, use Process

To aid in color timing and curve placement, negative originals should be timed relative to the Laboratory Aim Density (LAD) Control Film supplied by Eastman Kodak Company. The LAD Control Film provides both objective sensitometric control and subjective verification of the duplicating procedures used by the laboratory.

For print films, the LAD patch is printed to a neutral gray of 1.0 visual density (1.00 Equivalent Neutral Density) on the processed print at the setup lights.

The Status A densities are:

RGB

Density 1.09 1.06 1.03

For more information, see KODAK Publication No.

RECIPROCITY

You can print this film on a variety of printers, ranging from slow

PRINTER CONDITIONS

Pictorial Printing

The printer setup for KODAK VISION Premier Color Print Film / 2393 is similar to EASTMAN Color Print Film 2386 / E / 3386 / E, with little or no change required.

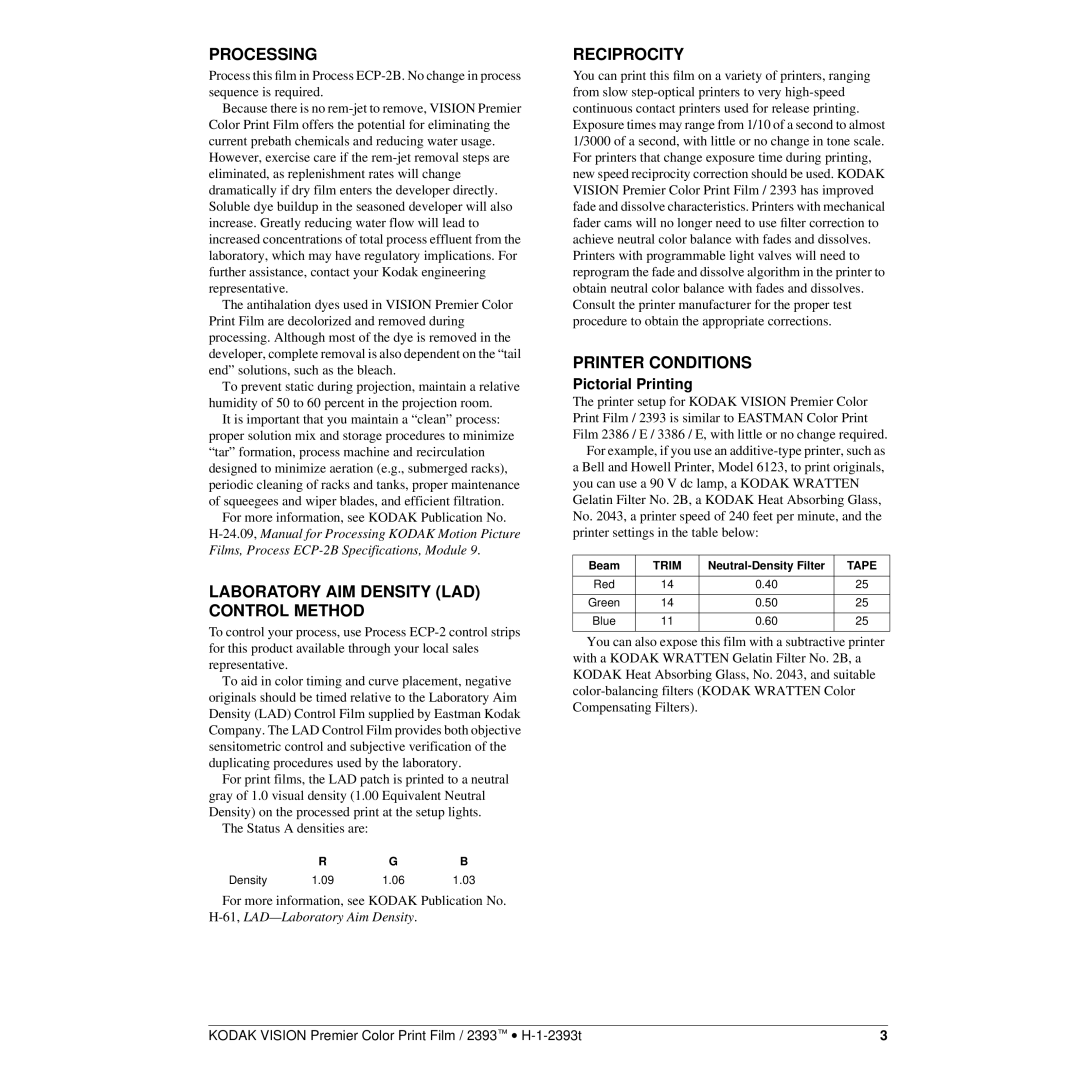

For example, if you use an

Beam | TRIM | TAPE | |

|

|

|

|

Red | 14 | 0.40 | 25 |

|

|

|

|

Green | 14 | 0.50 | 25 |

|

|

|

|

Blue | 11 | 0.60 | 25 |

|

|

|

|

You can also expose this film with a subtractive printer with a KODAK WRATTEN Gelatin Filter No. 2B, a KODAK Heat Absorbing Glass, No. 2043, and suitable

KODAK VISION Premier Color Print Film / 2393™ ∙ | 3 |