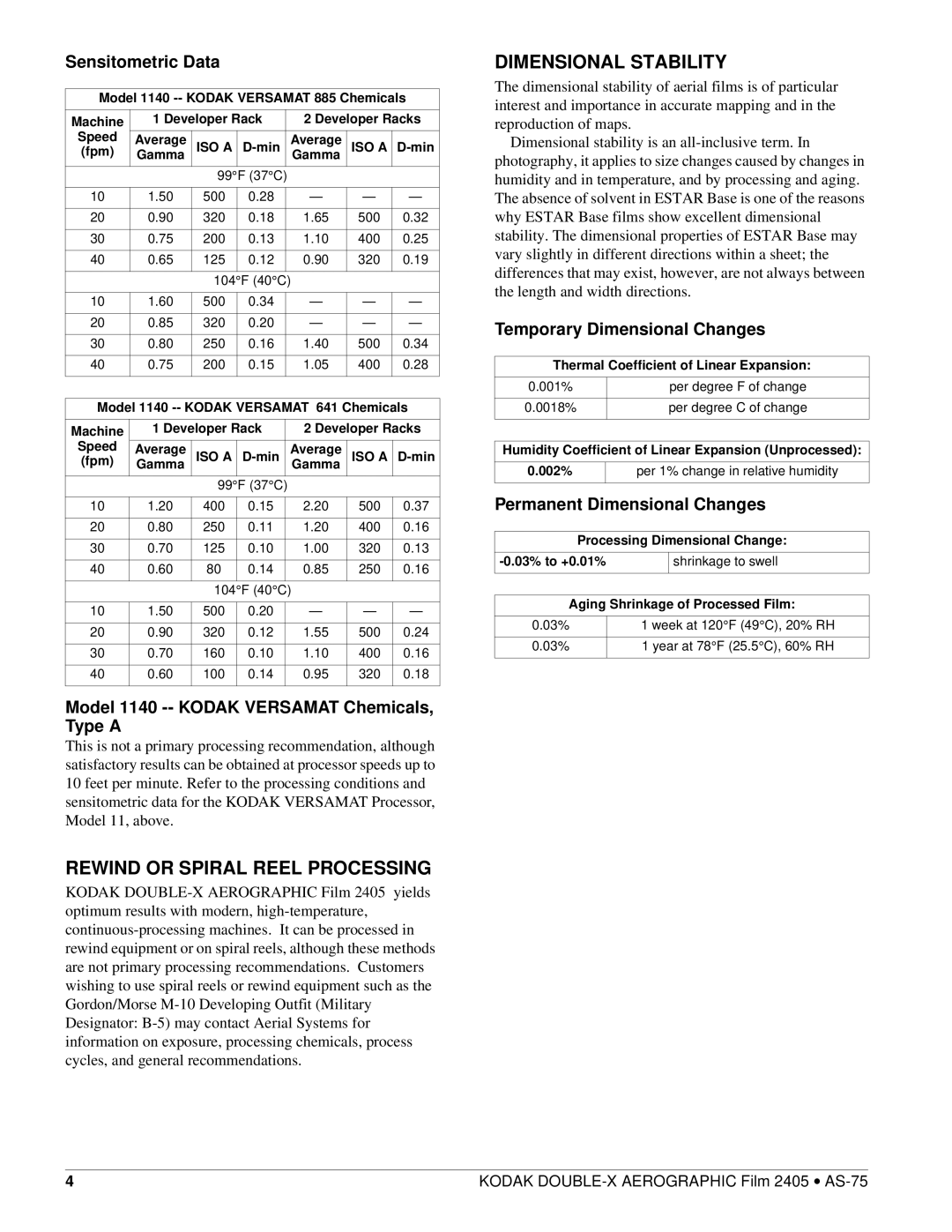

Sensitometric Data

Model 1140

Machine | 1 Developer Rack | 2 Developer Racks | |||||

Speed | Average | ISO A |

| Average | ISO A |

| |

(fpm) | Gamma | Gamma | |||||

|

|

|

|

|

|

|

|

|

| 99°F (37°C) |

|

|

| ||

|

|

|

|

|

|

|

|

10 | 1.50 | 500 | 0.28 |

| — | — | — |

|

|

|

|

|

|

|

|

20 | 0.90 | 320 | 0.18 |

| 1.65 | 500 | 0.32 |

|

|

|

|

|

|

|

|

30 | 0.75 | 200 | 0.13 |

| 1.10 | 400 | 0.25 |

|

|

|

|

|

|

|

|

40 | 0.65 | 125 | 0.12 |

| 0.90 | 320 | 0.19 |

|

|

|

|

|

|

|

|

|

| 104°F (40°C) |

|

| |||

|

|

|

|

|

|

|

|

10 | 1.60 | 500 | 0.34 |

| — | — | — |

|

|

|

|

|

|

|

|

20 | 0.85 | 320 | 0.20 |

| — | — | — |

|

|

|

|

|

|

|

|

30 | 0.80 | 250 | 0.16 |

| 1.40 | 500 | 0.34 |

|

|

|

|

|

|

|

|

40 | 0.75 | 200 | 0.15 |

| 1.05 | 400 | 0.28 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Model 1140 | |||||||

|

|

|

|

|

|

|

|

Machine | 1 Developer Rack |

| 2 Developer Racks | ||||

Speed | Average | ISO A |

|

| Average | ISO A |

|

(fpm) |

| ||||||

Gamma |

|

|

| Gamma |

|

| |

|

| 99° | F (37°C) |

|

|

|

|

|

|

|

|

|

|

|

|

10 | 1.20 | 400 | 0.15 |

| 2.20 | 500 | 0.37 |

|

|

|

|

|

|

|

|

20 | 0.80 | 250 | 0.11 |

| 1.20 | 400 | 0.16 |

|

|

|

|

|

|

|

|

30 | 0.70 | 125 | 0.10 |

| 1.00 | 320 | 0.13 |

|

|

|

|

|

|

|

|

40 | 0.60 | 80 | 0.14 |

| 0.85 | 250 | 0.16 |

|

|

|

|

|

|

| |

|

| 104 | °F (40°C) |

|

| ||

|

|

|

|

|

|

|

|

10 | 1.50 | 500 | 0.20 |

| — | — | — |

|

|

|

|

|

|

|

|

20 | 0.90 | 320 | 0.12 |

| 1.55 | 500 | 0.24 |

|

|

|

|

|

|

|

|

30 | 0.70 | 160 | 0.10 |

| 1.10 | 400 | 0.16 |

|

|

|

|

|

|

|

|

40 | 0.60 | 100 | 0.14 |

| 0.95 | 320 | 0.18 |

|

|

|

|

|

|

|

|

Model 1140 -- KODAK VERSAMAT Chemicals, Type A

This is not a primary processing recommendation, although satisfactory results can be obtained at processor speeds up to 10 feet per minute. Refer to the processing conditions and sensitometric data for the KODAK VERSAMAT Processor, Model 11, above.

REWIND OR SPIRAL REEL PROCESSING

KODAK

DIMENSIONAL STABILITY

The dimensional stability of aerial films is of particular interest and importance in accurate mapping and in the reproduction of maps.

Dimensional stability is an

Temporary Dimensional Changes

Thermal Coefficient of Linear Expansion:

0.001% | per degree F of change |

|

|

0.0018% | per degree C of change |

|

|

Humidity Coefficient of Linear Expansion (Unprocessed):

0.002% | per 1% change in relative humidity | |

|

|

|

Permanent Dimensional Changes | ||

|

|

|

Processing Dimensional Change: | ||

|

|

|

|

| shrinkage to swell |

|

|

|

|

| |

Aging Shrinkage of Processed Film: | ||

|

| |

0.03% | 1 week at 120°F (49°C), 20% RH | |

|

| |

0.03% | 1 year at 78°F (25.5°C), 60% RH | |

|

|

|

4 | KODAK |