Replenishment Rates

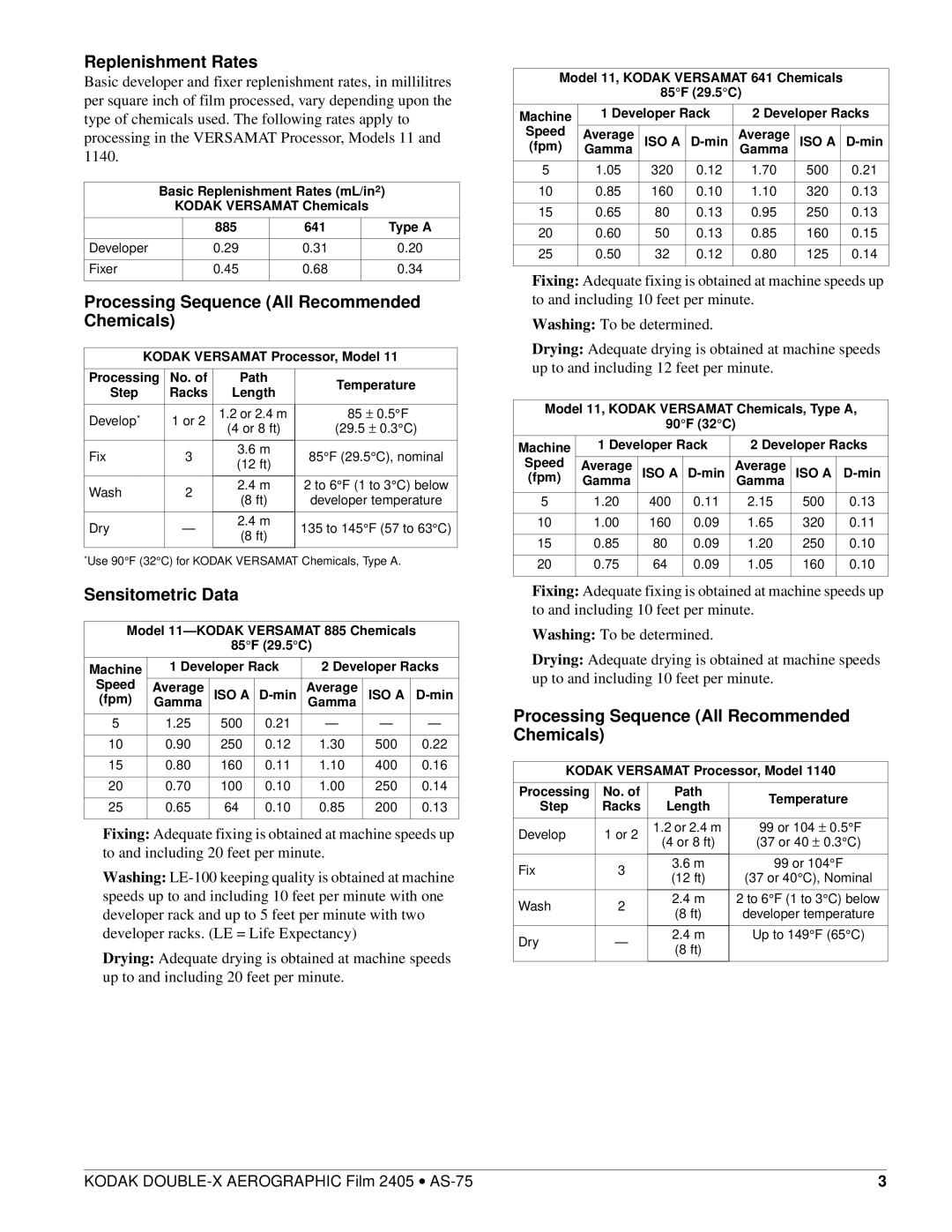

Basic developer and fixer replenishment rates, in millilitres per square inch of film processed, vary depending upon the type of chemicals used. The following rates apply to processing in the VERSAMAT Processor, Models 11 and 1140.

Basic Replenishment Rates (mL/in2)

KODAK VERSAMAT Chemicals

| 885 | 641 | Type A |

|

|

|

|

Developer | 0.29 | 0.31 | 0.20 |

|

|

|

|

Fixer | 0.45 | 0.68 | 0.34 |

|

|

|

|

Processing Sequence (All Recommended Chemicals)

KODAK VERSAMAT Processor, Model 11

Processing | No. of | Path | Temperature | |

Step | Racks | Length | ||

| ||||

|

|

|

| |

Develop* | 1 or 2 | 1.2 or 2.4 m | 85 ± 0.5°F | |

(4 or 8 ft) | (29.5 ± 0.3°C) | |||

|

| |||

|

|

|

| |

Fix | 3 | 3.6 m | 85°F (29.5°C), nominal | |

(12 ft) | ||||

|

|

| ||

|

|

|

| |

Wash | 2 | 2.4 m | 2 to 6°F (1 to 3°C) below | |

(8 ft) | developer temperature | |||

|

| |||

|

|

|

| |

Dry | — | 2.4 m | 135 to 145°F (57 to 63°C) | |

(8 ft) | ||||

|

|

| ||

|

|

|

|

*Use 90°F (32°C) for KODAK VERSAMAT Chemicals, Type A.

Sensitometric Data

Model

85°F (29.5°C)

Machine | 1 Developer Rack | 2 Developer Racks | ||||

Speed | Average | ISO A |

| Average | ISO A | |

(fpm) | Gamma | Gamma | ||||

|

|

|

|

|

|

|

5 | 1.25 | 500 | 0.21 | — | — | — |

|

|

|

|

|

|

|

10 | 0.90 | 250 | 0.12 | 1.30 | 500 | 0.22 |

|

|

|

|

|

|

|

15 | 0.80 | 160 | 0.11 | 1.10 | 400 | 0.16 |

|

|

|

|

|

|

|

20 | 0.70 | 100 | 0.10 | 1.00 | 250 | 0.14 |

|

|

|

|

|

|

|

25 | 0.65 | 64 | 0.10 | 0.85 | 200 | 0.13 |

|

|

|

|

|

|

|

Fixing: Adequate fixing is obtained at machine speeds up to and including 20 feet per minute.

Washing:

Drying: Adequate drying is obtained at machine speeds up to and including 20 feet per minute.

Model 11, KODAK VERSAMAT 641 Chemicals

85°F (29.5°C)

Machine | 1 Developer Rack | 2 Developer Racks | |||||

Speed | Average | ISO A | Average | ISO A | |||

(fpm) | |||||||

Gamma |

|

| Gamma |

|

| ||

5 | 1.05 | 320 | 0.12 | 1.70 | 500 | 0.21 | |

|

|

|

|

|

|

| |

10 | 0.85 | 160 | 0.10 | 1.10 | 320 | 0.13 | |

|

|

|

|

|

|

| |

15 | 0.65 | 80 | 0.13 | 0.95 | 250 | 0.13 | |

|

|

|

|

|

|

| |

20 | 0.60 | 50 | 0.13 | 0.85 | 160 | 0.15 | |

|

|

|

|

|

|

| |

25 | 0.50 | 32 | 0.12 | 0.80 | 125 | 0.14 | |

|

|

|

|

|

|

| |

Fixing: Adequate fixing is obtained at machine speeds up to and including 10 feet per minute.

Washing: To be determined.

Drying: Adequate drying is obtained at machine speeds up to and including 12 feet per minute.

Model 11, KODAK VERSAMAT Chemicals, Type A,

90°F (32°C)

Machine | 1 Developer Rack | 2 Developer Racks | ||||

Speed | Average | ISO A | Average | ISO A | ||

(fpm) | Gamma | Gamma | ||||

|

|

|

|

|

|

|

5 | 1.20 | 400 | 0.11 | 2.15 | 500 | 0.13 |

|

|

|

|

|

|

|

10 | 1.00 | 160 | 0.09 | 1.65 | 320 | 0.11 |

|

|

|

|

|

|

|

15 | 0.85 | 80 | 0.09 | 1.20 | 250 | 0.10 |

|

|

|

|

|

|

|

20 | 0.75 | 64 | 0.09 | 1.05 | 160 | 0.10 |

|

|

|

|

|

|

|

Fixing: Adequate fixing is obtained at machine speeds up to and including 10 feet per minute.

Washing: To be determined.

Drying: Adequate drying is obtained at machine speeds up to and including 10 feet per minute.

Processing Sequence (All Recommended Chemicals)

KODAK VERSAMAT Processor, Model 1140

Processing | No. of | Path | Temperature | |

Step | Racks | Length | ||

| ||||

|

|

|

| |

Develop | 1 or 2 | 1.2 or 2.4 m | 99 or 104 ± 0.5°F | |

(4 or 8 ft) | (37 or 40 ± 0.3°C) | |||

|

| |||

|

|

|

| |

Fix | 3 | 3.6 m | 99 or 104°F | |

(12 ft) | (37 or 40°C), Nominal | |||

|

| |||

|

|

|

| |

Wash | 2 | 2.4 m | 2 to 6°F (1 to 3°C) below | |

(8 ft) | developer temperature | |||

|

| |||

|

|

|

| |

Dry | — | 2.4 m | Up to 149°F (65°C) | |

(8 ft) |

| |||

|

|

| ||

|

|

|

|

KODAK | 3 |