Process C-41RA

This film process cycle is the shortest of the Process

Process

Although Process

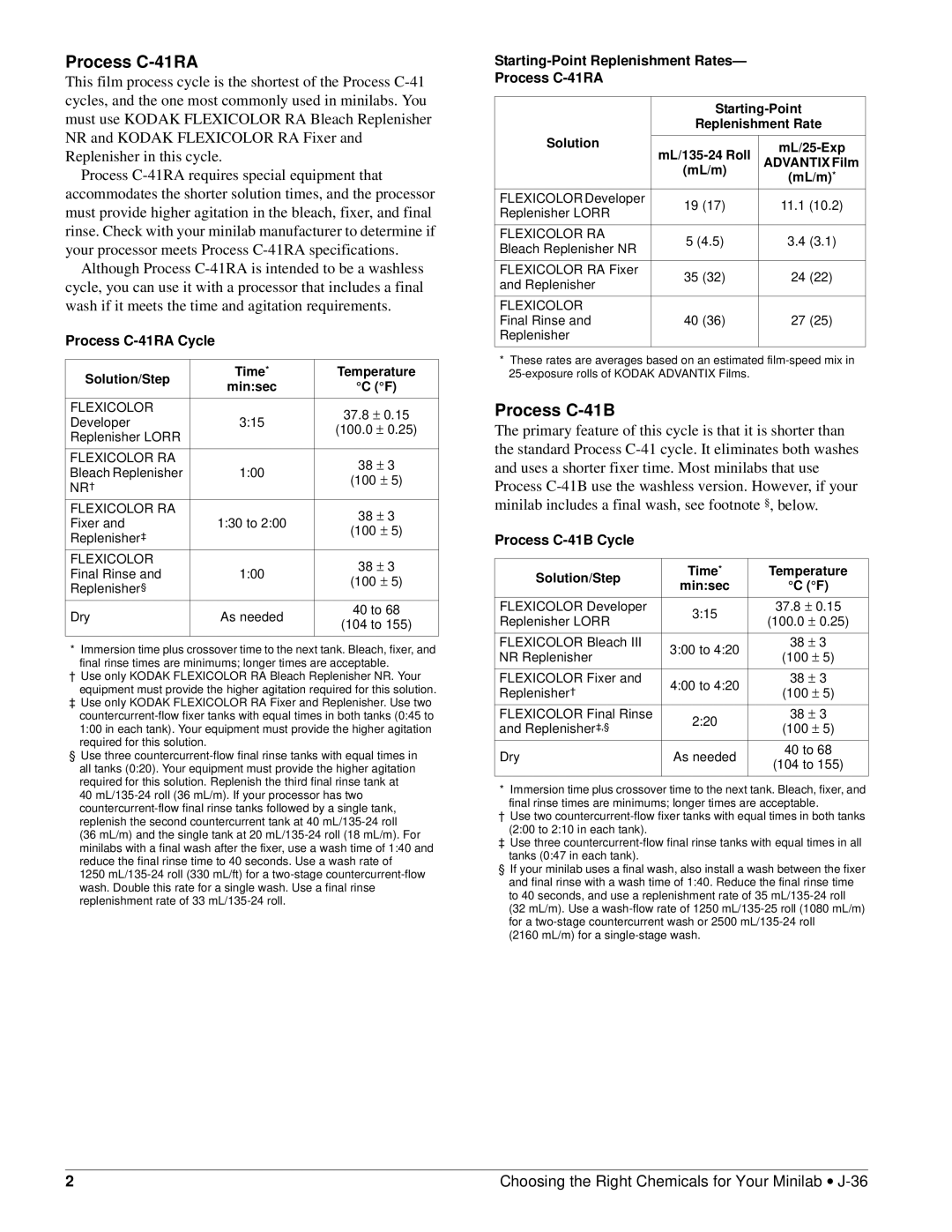

Process C-41RA Cycle

Solution/Step | Time* | Temperature | |||

min:sec | °C (°F) | ||||

| |||||

|

|

|

|

| |

FLEXICOLOR |

| 37.8 ± |

| 0.15 | |

Developer | 3:15 |

| |||

(100.0 | ± | 0.25) | |||

Replenisher LORR |

| ||||

|

|

|

| ||

|

|

|

|

| |

FLEXICOLOR RA | 1:00 | 38 | ± | 3 | |

Bleach Replenisher | |||||

(100 | ± | 5) | |||

NR† |

| ||||

|

|

|

| ||

FLEXICOLOR RA | 1:30 to 2:00 | 38 | ± | 3 | |

Fixer and | |||||

(100 | ± | 5) | |||

Replenisher‡ |

| ||||

|

|

|

| ||

FLEXICOLOR | 1:00 | 38 | ± | 3 | |

Final Rinse and | |||||

(100 | ± | 5) | |||

Replenisher§ |

| ||||

|

|

|

| ||

Dry | As needed | 40 to 68 | |||

(104 to 155) | |||||

|

| ||||

* Immersion time plus crossover time to the next tank. Bleach, fixer, and final rinse times are minimums; longer times are acceptable.

† Use only KODAK FLEXICOLOR RA Bleach Replenisher NR. Your equipment must provide the higher agitation required for this solution.

‡Use only KODAK FLEXICOLOR RA Fixer and Replenisher. Use two

required for this solution.

§Use three

(36 mL/m) and the single tank at 20

1250

Starting-Point Replenishment Rates—

Process C-41RA

|

| |||

| Replenishment Rate | |||

Solution |

|

|

| |

|

| |||

| ADVANTIX Film | |||

| (mL/m) | (mL/m)* | ||

|

| |||

FLEXICOLOR Developer | 19 (17) | 11.1 | (10.2) | |

Replenisher LORR | ||||

|

|

| ||

FLEXICOLOR RA | 5 (4.5) | 3.4 | (3.1) | |

Bleach Replenisher NR | ||||

|

|

| ||

FLEXICOLOR RA Fixer | 35 (32) | 24 | (22) | |

and Replenisher | ||||

|

|

| ||

|

|

|

| |

FLEXICOLOR |

|

|

| |

Final Rinse and | 40 (36) | 27 | (25) | |

Replenisher |

|

|

| |

*These rates are averages based on an estimated

Process C-41B

The primary feature of this cycle is that it is shorter than the standard Process

Process C-41B Cycle

Solution/Step | Time* | Temperature | |||

min:sec | °C (°F) | ||||

| |||||

|

|

|

|

| |

FLEXICOLOR Developer | 3:15 | 37.8 ± |

| 0.15 | |

Replenisher LORR | (100.0 | ± | 0.25) | ||

| |||||

|

|

|

|

| |

FLEXICOLOR Bleach III | 3:00 to 4:20 | 38 | ± | 3 | |

NR Replenisher | (100 ± | 5) | |||

| |||||

FLEXICOLOR Fixer and | 4:00 to 4:20 | 38 | ± | 3 | |

Replenisher† | (100 ± | 5) | |||

| |||||

FLEXICOLOR Final Rinse | 2:20 | 38 | ± | 3 | |

and Replenisher‡,§ | (100 ± | 5) | |||

| |||||

Dry | As needed | 40 to 68 | |||

(104 to 155) | |||||

|

| ||||

* Immersion time plus crossover time to the next tank. Bleach, fixer, and final rinse times are minimums; longer times are acceptable.

† Use two

‡ Use three

§If your minilab uses a final wash, also install a wash between the fixer and final rinse with a wash time of 1:40. Reduce the final rinse time to 40 seconds, and use a replenishment rate of 35

(32 mL/m). Use a

(2160 mL/m) for a

2 | Choosing the Right Chemicals for Your Minilab • |