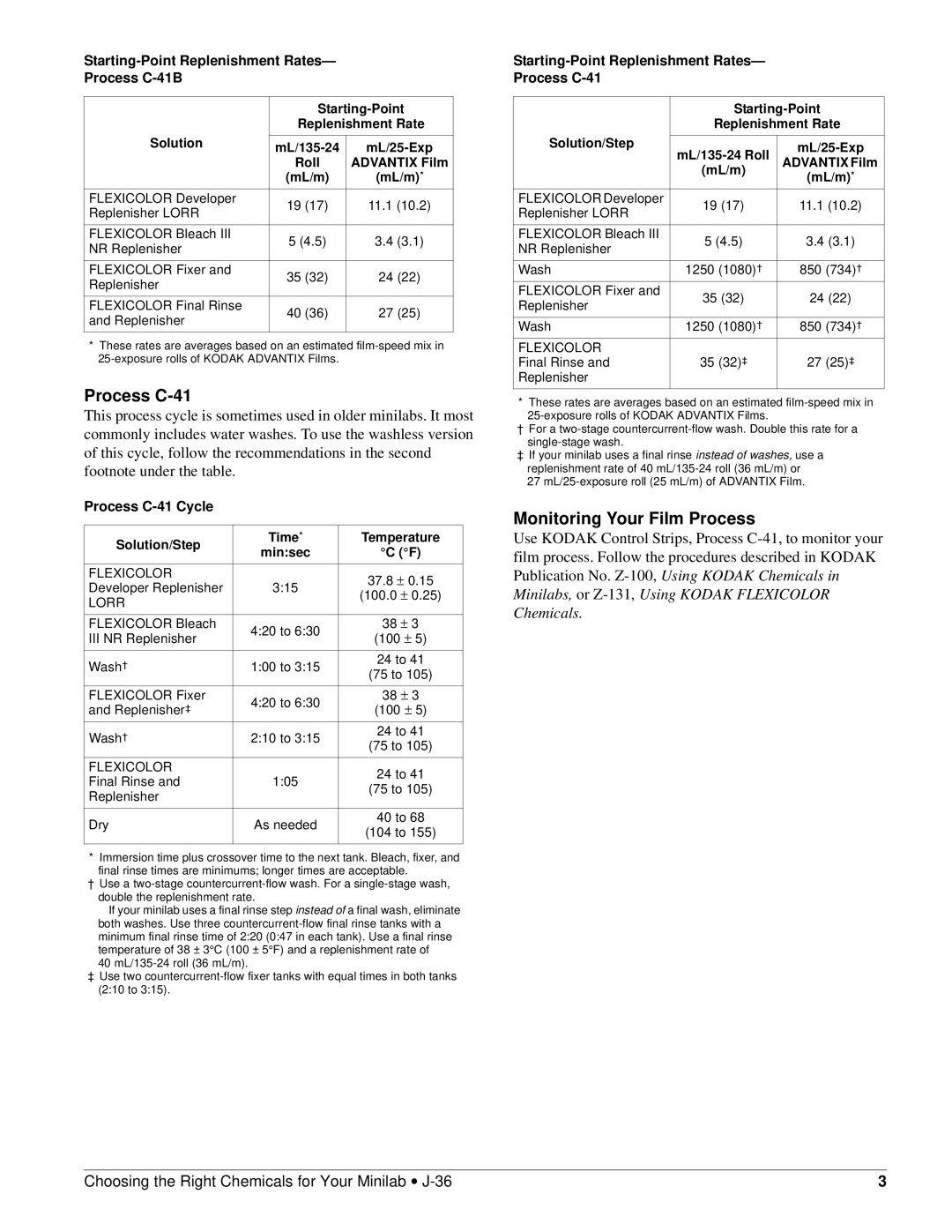

Starting-Point Replenishment Rates—

Process C-41B

| |||

| Replenishment Rate | ||

Solution |

|

| |

|

| ||

| Roll | ADVANTIX Film | |

| (mL/m) | (mL/m)* | |

FLEXICOLOR Developer | 19 (17) | 11.1 (10.2) | |

Replenisher LORR | |||

|

| ||

FLEXICOLOR Bleach III | 5 (4.5) | 3.4 (3.1) | |

NR Replenisher | |||

|

| ||

FLEXICOLOR Fixer and | 35 (32) | 24 (22) | |

Replenisher | |||

|

| ||

|

|

| |

FLEXICOLOR Final Rinse | 40 (36) | 27 (25) | |

and Replenisher | |||

|

| ||

*These rates are averages based on an estimated

Process C-41

This process cycle is sometimes used in older minilabs. It most commonly includes water washes. To use the washless version of this cycle, follow the recommendations in the second footnote under the table.

Process C-41 Cycle

Solution/Step | Time* | Temperature | ||

min:sec | °C (°F) | |||

| ||||

|

|

|

| |

FLEXICOLOR |

| 37.8 ± | 0.15 | |

Developer Replenisher | 3:15 | |||

(100.0 ± | 0.25) | |||

LORR |

| |||

|

|

| ||

|

|

|

| |

FLEXICOLOR Bleach | 4:20 to 6:30 | 38 ± | 3 | |

III NR Replenisher | (100 ± | 5) | ||

| ||||

Wash† | 1:00 to 3:15 | 24 to 41 | ||

(75 to 105) | ||||

|

| |||

|

|

|

| |

FLEXICOLOR Fixer | 4:20 to 6:30 | 38 ± | 3 | |

and Replenisher‡ | (100 ± | 5) | ||

| ||||

Wash† | 2:10 to 3:15 | 24 to 41 | ||

(75 to 105) | ||||

|

| |||

FLEXICOLOR |

| 24 to 41 | ||

Final Rinse and | 1:05 | |||

(75 to 105) | ||||

Replenisher |

| |||

|

|

| ||

|

|

| ||

Dry | As needed | 40 to 68 | ||

(104 to 155) | ||||

|

| |||

*Immersion time plus crossover time to the next tank. Bleach, fixer, and final rinse times are minimums; longer times are acceptable.

†Use a

If your minilab uses a final rinse step instead of a final wash, eliminate both washes. Use three

40

‡Use two

Starting-Point Replenishment Rates—

Process C-41

| |||

| Replenishment Rate | ||

Solution/Step |

|

| |

|

| ||

| ADVANTIX Film | ||

| (mL/m) | (mL/m)* | |

|

| ||

FLEXICOLOR Developer | 19 (17) | 11.1 (10.2) | |

Replenisher LORR | |||

|

| ||

FLEXICOLOR Bleach III | 5 (4.5) | 3.4 (3.1) | |

NR Replenisher | |||

|

| ||

Wash | 1250 (1080)† | 850 (734)† | |

FLEXICOLOR Fixer and | 35 (32) | 24 (22) | |

Replenisher | |||

|

| ||

|

|

| |

Wash | 1250 (1080)† | 850 (734)† | |

FLEXICOLOR |

| 27 (25)‡ | |

Final Rinse and | 35 (32)‡ | ||

Replenisher |

|

| |

* These rates are averages based on an estimated

†For a

‡If your minilab uses a final rinse instead of washes, use a replenishment rate of 40

27

Monitoring Your Film Process

Use KODAK Control Strips, Process

Choosing the Right Chemicals for Your Minilab • | 3 |