USING KODAK CONTROL STRIPS, PROCESS

Use KODAK Control Strips, Process

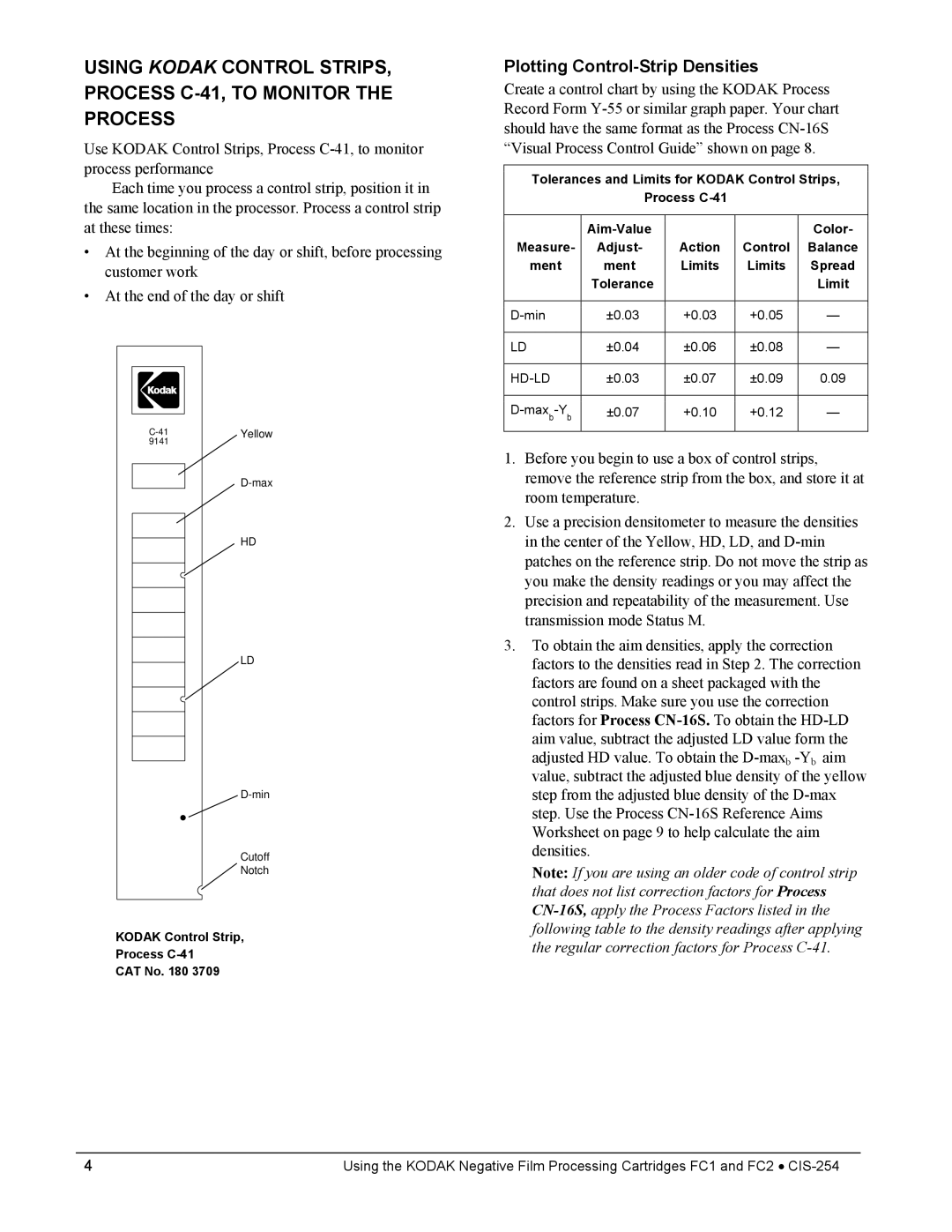

Each time you process a control strip, position it in the same location in the processor. Process a control strip at these times:

•At the beginning of the day or shift, before processing customer work

•At the end of the day or shift

9141

HD

LD

Cutoff

Notch

KODAK Control Strip,

Process

CAT No. 180 3709

Plotting Control-Strip Densities

Create a control chart by using the KODAK Process Record Form

Tolerances and Limits for KODAK Control Strips,

Process

|

|

| Color- | |

Measure- | Adjust- | Action | Control | Balance |

ment | ment | Limits | Limits | Spread |

| Tolerance |

|

| Limit |

|

|

|

|

|

±0.03 | +0.03 | +0.05 | — | |

|

|

|

|

|

LD | ±0.04 | ±0.06 | ±0.08 | — |

|

|

|

|

|

±0.03 | ±0.07 | ±0.09 | 0.09 | |

|

|

|

|

|

±0.07 | +0.10 | +0.12 | — | |

|

|

|

|

|

1.Before you begin to use a box of control strips, remove the reference strip from the box, and store it at room temperature.

2.Use a precision densitometer to measure the densities in the center of the Yellow, HD, LD, and

3.To obtain the aim densities, apply the correction factors to the densities read in Step 2. The correction factors are found on a sheet packaged with the control strips. Make sure you use the correction factors for Process

adjusted HD value. To obtain the

Note: If you are using an older code of control strip that does not list correction factors for Process

4 | Using the KODAK Negative Film Processing Cartridges FC1 and FC2 • |