PROCESSING

KODAK

Mechanized processing in

General instructions for setting the machine dryer temperature are included in these pages. However, the temperature of the dryer may require some further adjustment, depending upon the ambient temperature conditions in the processing area. Usually it is best to set the temperature approximately 3° F (2° C) above that required to dry unexposed, processed film.

Chemicals

The following KODAK VERSAMAT Chemicals may be used in both the Model 11 and Model 1140 VERSAMAT Processors.

KODAK VERSAMAT 885 Developer Starter

KODAK VERSAMAT 885 Developer Replenisher

KODAK VERSAMAT 885 Fixer and Replenisher

KODAK VERSAMAT 641 Developer Starter

KODAK VERSAMAT 641 Developer Replenisher

KODAK VERSAMAT 641 Fixer and Replenisher

KODAK VERSAMAT Developer Starter, Type A

KODAK VERSAMAT Developer Replenisher, Type A

KODAK VERSAMAT Fixer and Replenisher, Type A

Notice: Observe precautionary information on product labels and Material Safety Data Sheets.

Replenishment Rates

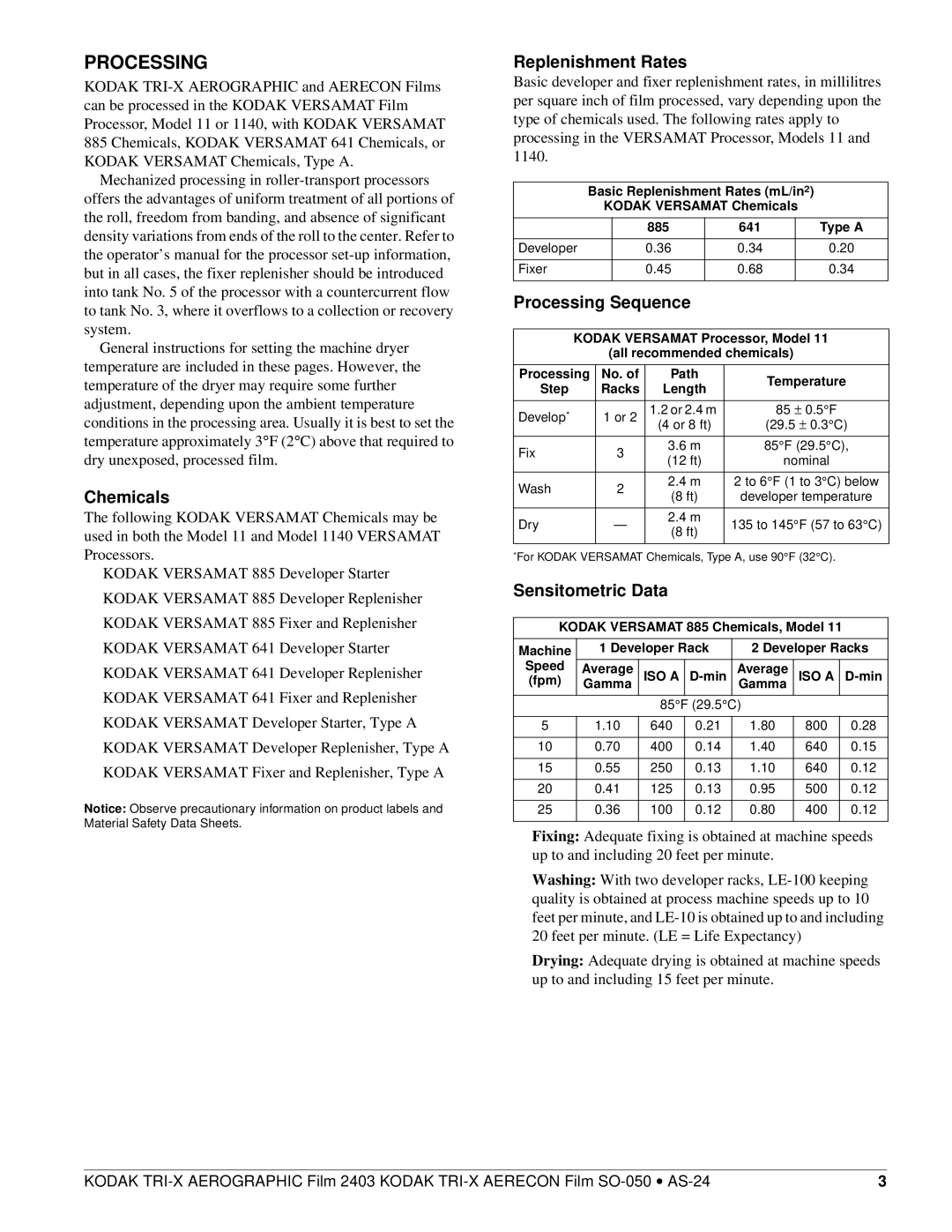

Basic developer and fixer replenishment rates, in millilitres per square inch of film processed, vary depending upon the type of chemicals used. The following rates apply to processing in the VERSAMAT Processor, Models 11 and 1140.

|

| Basic Replenishment Rates (mL/in2) |

| ||||||||||||

|

|

| KODAK VERSAMAT Chemicals |

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| 885 |

|

|

| 641 |

| Type A | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Developer |

|

|

|

| 0.36 |

|

|

| 0.34 |

| 0.20 | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Fixer |

|

|

|

| 0.45 |

|

|

| 0.68 |

| 0.34 | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

Processing Sequence |

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

| |||||

KODAK VERSAMAT Processor, Model 11 |

| ||||||||||||||

|

|

| (all recommended chemicals) |

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

| ||||

Processing | No. of |

| Path |

| Temperature | ||||||||||

Step |

| Racks |

| Length |

| ||||||||||

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

Develop* |

| 1 or 2 |

| 1.2 or 2.4 m |

| 85 ± | 0.5° F |

| |||||||

|

|

|

|

|

|

| (4 or 8 ft) |

| (29.5 ± | 0.3° C) | |||||

Fix |

| 3 |

|

| 3.6 m |

| 85° F (29.5° C), | ||||||||

|

|

| (12 ft) |

| nominal |

| |||||||||

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Wash |

| 2 |

|

| 2.4 m |

| 2 to 6° F (1 to 3° C) below | ||||||||

|

|

| (8 ft) |

| developer temperature | ||||||||||

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Dry |

|

| — |

| 2.4 m |

| 135 to 145° F (57 to 63° C) | ||||||||

|

|

| (8 ft) |

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

| |||||

*For KODAK VERSAMAT Chemicals, Type A, use 90° F (32° C). |

| ||||||||||||||

Sensitometric Data |

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

| ||||||||

KODAK VERSAMAT 885 Chemicals, Model 11 |

| ||||||||||||||

|

|

|

|

|

|

|

| ||||||||

Machine |

|

| 1 Developer Rack | 2 Developer Racks | |||||||||||

Speed |

| Average |

| ISO A | Average | ISO A |

| ||||||||

(fpm) |

|

|

| ||||||||||||

| Gamma |

|

|

|

|

|

| Gamma |

|

|

|

| |||

|

|

|

|

|

|

| 85° F (29.5° C) |

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

| ||||

5 |

| 1.10 |

| 640 | 0.21 |

| 1.80 |

| 800 |

| 0.28 | ||||

|

|

|

|

|

|

|

|

|

|

|

| ||||

10 |

| 0.70 |

| 400 | 0.14 |

| 1.40 |

| 640 |

| 0.15 | ||||

|

|

|

|

|

|

|

|

|

|

|

| ||||

15 |

| 0.55 |

| 250 | 0.13 |

| 1.10 |

| 640 |

| 0.12 | ||||

|

|

|

|

|

|

|

|

|

|

|

| ||||

20 |

| 0.41 |

| 125 | 0.13 |

| 0.95 |

| 500 |

| 0.12 | ||||

|

|

|

|

|

|

|

|

|

|

|

| ||||

25 |

| 0.36 |

| 100 | 0.12 |

| 0.80 |

| 400 |

| 0.12 | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fixing: Adequate fixing is obtained at machine speeds up to and including 20 feet per minute.

Washing: With two developer racks,

Drying: Adequate drying is obtained at machine speeds up to and including 15 feet per minute.

KODAK | 3 |