READ AND UNDERSTAND ALL TRACK, CONNECTOR,

INSTRUCTION SHEETS BEFORE INSTALLING ANY TRACK ITEM.

This fixture is intended for installation in accordance with the National Electrical Code and local or Federal code specifications. To assure full compliance with codes and regulations, check with your local electrical inspector before installation. To prevent electric shock, turn off electricity at fuse box before proceeding.

Retain these instructions for maintenance reference.

INSTRUCTION SHEET NO.

IS:7480

B1197 | Page 1 of 2 |

Installation Instructions for Swivel Stem Mounting Kits for use with Lytespan and ProSpec™ Track Systems Only.

Caution:

• | Turn off power at fuse box before installing track. |

• Instructions for grounding must be followed. Failure to do | |

| so may result in a hazardous condition. |

• Use only #12 ga. solid copper wire in connectors to maintain | |

| proper track rating. |

• | Do not supply Advent Track from two separate 120V branch |

| circuits as this could overload the neutral track conductor |

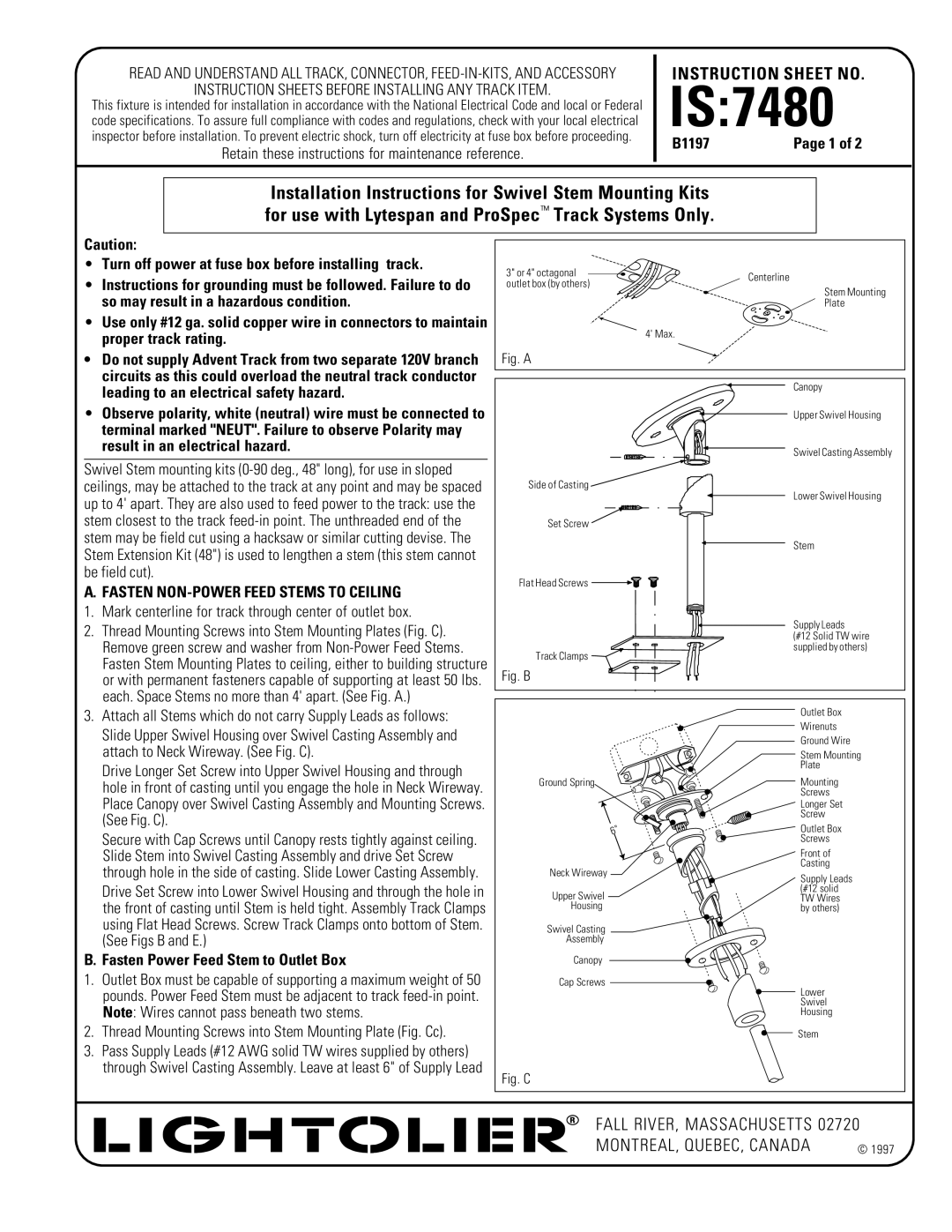

3" or 4" octagonal | Centerline | |

outlet box (by others) | ||

|

Stem Mounting

Plate

4' Max.

Fig. A

leading to an electrical safety hazard. |

• Observe polarity, white (neutral) wire must be connected to |

terminal marked "NEUT". Failure to observe Polarity may |

result in an electrical hazard. |

Swivel Stem mounting kits

A.FASTEN NON-POWER FEED STEMS TO CEILING

1. Mark centerline for track through center of outlet box.

2. Thread Mounting Screws into Stem Mounting Plates (Fig. C). |

Remove green screw and washer from |

Fasten Stem Mounting Plates to ceiling, either to building structure |

or with permanent fasteners capable of supporting at least 50 lbs. |

each. Space Stems no more than 4' apart. (See Fig. A.) |

Side of Casting

Set Screw

Flat Head Screws ![]()

![]()

Track Clamps

Fig. B

Canopy

Upper Swivel Housing

Swivel Casting Assembly

Lower Swivel Housing

Stem

Supply Leads

(#12 Solid TW wire supplied by others)

3. Attach all Stems which do not carry Supply Leads as follows: |

Slide Upper Swivel Housing over Swivel Casting Assembly and |

attach to Neck Wireway. (See Fig. C). |

Drive Longer Set Screw into Upper Swivel Housing and through |

hole in front of casting until you engage the hole in Neck Wireway. |

Place Canopy over Swivel Casting Assembly and Mounting Screws. |

(See Fig. C). |

Secure with Cap Screws until Canopy rests tightly against ceiling. |

Slide Stem into Swivel Casting Assembly and drive Set Screw |

through hole in the side of casting. Slide Lower Casting Assembly. |

Drive Set Screw into Lower Swivel Housing and through the hole in the front of casting until Stem is held tight. Assembly Track Clamps using Flat Head Screws. Screw Track Clamps onto bottom of Stem. (See Figs B and E.)

Ground Spring

Neck Wireway

Upper Swivel

Housing

Swivel Casting |

Assembly |

Outlet Box

Wirenuts

Ground Wire

Stem Mounting

Plate

Mounting

Screws

Longer Set

Screw

Outlet Box

Screws

Front of

Casting

Supply Leads (#12 solid TW Wires by others)

B. Fasten Power Feed Stem to Outlet Box

1.Outlet Box must be capable of supporting a maximum weight of 50 pounds. Power Feed Stem must be adjacent to track

2.Thread Mounting Screws into Stem Mounting Plate (Fig. Cc).

3.Pass Supply Leads (#12 AWG solid TW wires supplied by others) through Swivel Casting Assembly. Leave at least 6" of Supply Lead

Canopy

Cap Screws

Lower

Swivel

Housing

Stem

Fig. C

FALL RIVER, MASSACHUSETTS 02720

MONTREAL, QUEBEC, CANADA | © 1997 |