Calculite® HID Wall Wash C4T4W

Page 1 of 2

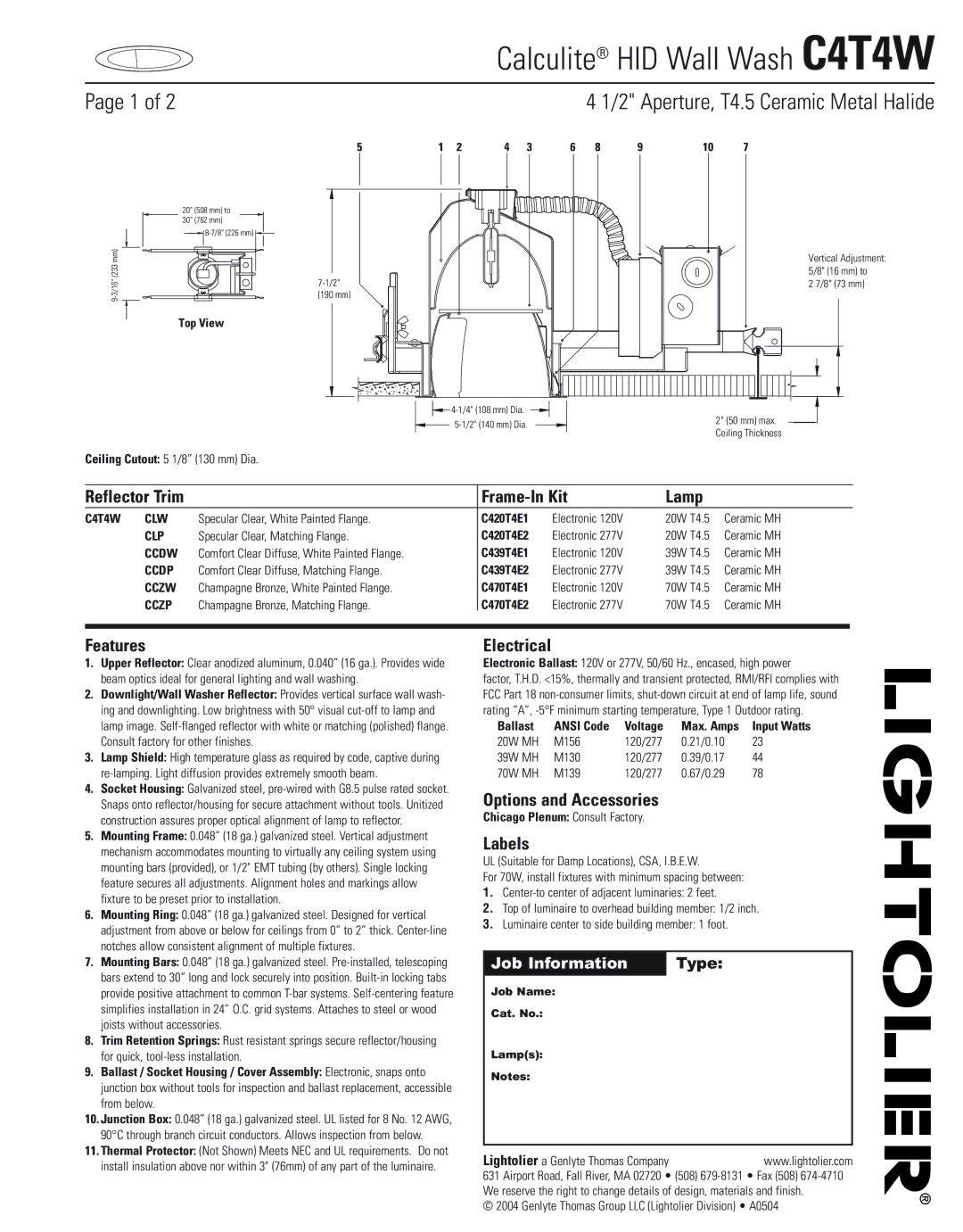

5

| 20" (508 mm) to |

| 30" (762 mm) |

| |

(233 mm) | (190 mm) |

|

Top View

Ceiling Cutout: 5 1/8” (130 mm) Dia.

Reflector Trim

C4T4W | CLW | Specular Clear, White Painted Flange. |

| CLP | Specular Clear, Matching Flange. |

| CCDW | Comfort Clear Diffuse, White Painted Flange. |

| CCDP | Comfort Clear Diffuse, Matching Flange. |

| CCZW | Champagne Bronze, White Painted Flange. |

| CCZP | Champagne Bronze, Matching Flange. |

4 1/2" Aperture, T4.5 Ceramic Metal Halide

1 | 2 | 4 | 3 | 6 | 8 | 9 | 10 | 7 |

Vertical Adjustment: 5/8" (16 mm) to

2 7/8" (73 mm)

2" (50 mm) max. | ||

Ceiling Thickness | ||

|

| Lamp |

| |

C420T4E1 | Electronic 120V | 20W T4.5 | Ceramic MH |

C420T4E2 | Electronic 277V | 20W T4.5 | Ceramic MH |

C439T4E1 | Electronic 120V | 39W T4.5 | Ceramic MH |

C439T4E2 | Electronic 277V | 39W T4.5 | Ceramic MH |

C470T4E1 | Electronic 120V | 70W T4.5 | Ceramic MH |

C470T4E2 | Electronic 277V | 70W T4.5 | Ceramic MH |

Features

1.Upper Reflector: Clear anodized aluminum, 0.040” (16 ga.). Provides wide beam optics ideal for general lighting and wall washing.

2.Downlight/Wall Washer Reflector: Provides vertical surface wall wash- ing and downlighting. Low brightness with 50° visual

3.Lamp Shield: High temperature glass as required by code, captive during

4.Socket Housing: Galvanized steel,

5.Mounting Frame: 0.048” (18 ga.) galvanized steel. Vertical adjustment mechanism accommodates mounting to virtually any ceiling system using mounting bars (provided), or 1/2" EMT tubing (by others). Single locking feature secures all adjustments. Alignment holes and markings allow fixture to be preset prior to installation.

6.Mounting Ring: 0.048” (18 ga.) galvanized steel. Designed for vertical adjustment from above or below for ceilings from 0” to 2” thick.

7.Mounting Bars: 0.048” (18 ga.) galvanized steel.

8.Trim Retention Springs: Rust resistant springs secure reflector/housing for quick,

9.Ballast / Socket Housing / Cover Assembly: Electronic, snaps onto junction box without tools for inspection and ballast replacement, accessible from below.

10.Junction Box: 0.048” (18 ga.) galvanized steel. UL listed for 8 No. 12 AWG, 90°C through branch circuit conductors. Allows inspection from below.

11.Thermal Protector: (Not Shown) Meets NEC and UL requirements. Do not install insulation above nor within 3" (76mm) of any part of the luminaire.

Electrical

Electronic Ballast: 120V or 277V, 50/60 Hz., encased, high power

factor, T.H.D. <15%, thermally and transient protected, RMI/RFI complies with FCC Part 18

Ballast | ANSI Code | Voltage | Max. Amps | Input Watts |

20W MH | M156 | 120/277 | 0.21/0.10 | 23 |

39W MH | M130 | 120/277 | 0.39/0.17 | 44 |

70W MH | M139 | 120/277 | 0.67/0.29 | 78 |

Options and Accessories

Chicago Plenum: Consult Factory.

Labels

UL (Suitable for Damp Locations), CSA, I.B.E.W.

For 70W, install fixtures with minimum spacing between:

1.

2.Top of luminaire to overhead building member: 1/2 inch.

3.Luminaire center to side building member: 1 foot.

Job Information | Type: |

|

|

Job Name:

Cat. No.:

Lamp(s):

Notes:

Lightolier a Genlyte Thomas Companywww.lightolier.com 631 Airport Road, Fall River, MA 02720 • (508)

© 2004 Genlyte Thomas Group LLC (Lightolier Division) • A0504