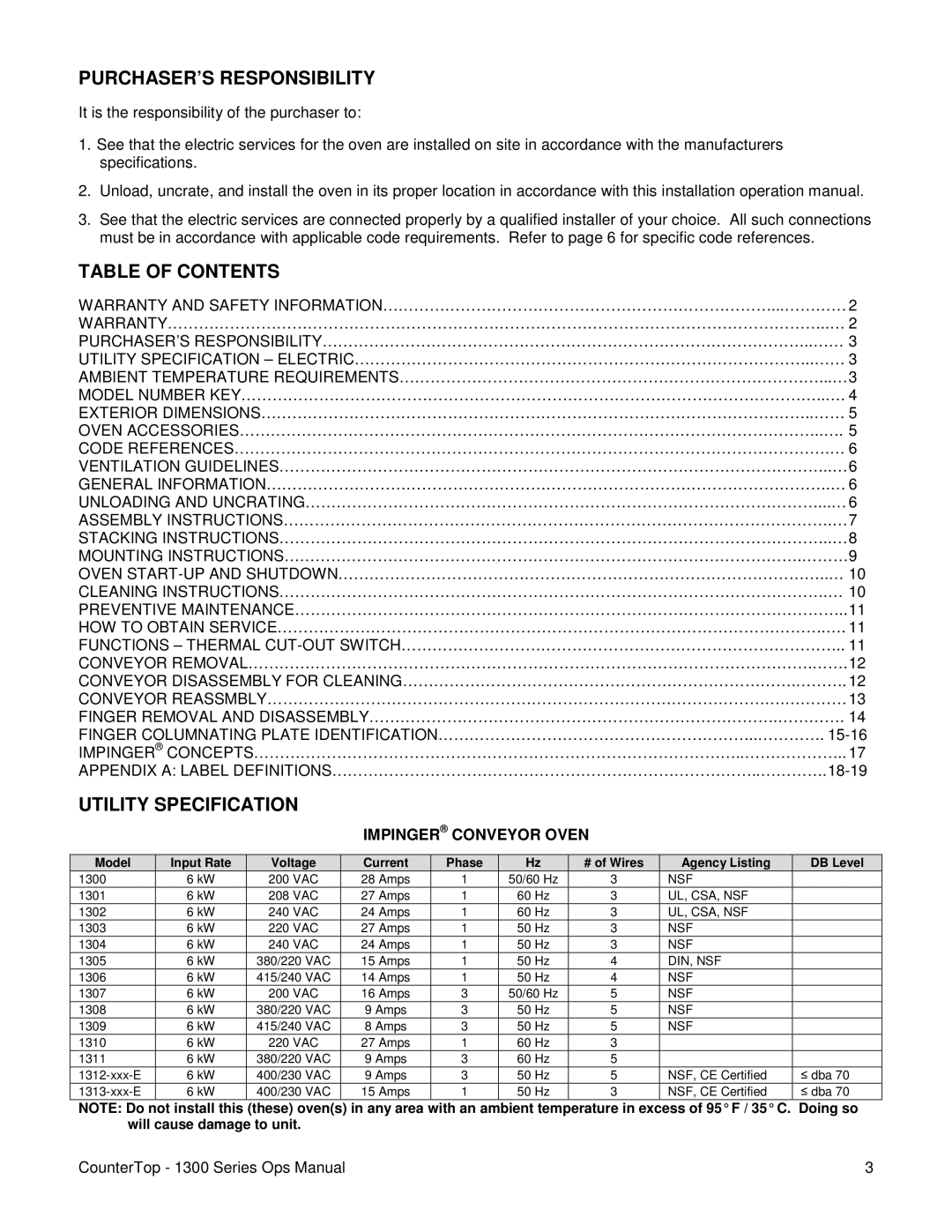

1300 Series specifications

The Lincoln 1300 Series is a well-regarded line of welding machines that showcases the brand's commitment to quality, innovation, and user-friendliness. These machines are designed to meet the diverse needs of both professionals and hobbyists in various welding applications.One of the most notable features of the Lincoln 1300 Series is its versatility. This series includes models that can handle a range of welding processes such as MIG, TIG, and stick welding. This multi-process capability makes them suitable for a multitude of projects, whether you are working with thin sheet metal or thicker materials. Users appreciate the flexibility that this series provides, allowing them to tackle different materials without needing multiple machines.

The technology integrated into the Lincoln 1300 Series also sets it apart from competitors. Advanced inverter technology is commonly used, leading to increased efficiency and power savings. Inverter technology enables the machines to produce a more stable arc while reducing the weight and size of the units, making them portable and easy to handle. This technology not only enhances performance but also extends the lifespan of the equipment.

Moreover, the Lincoln 1300 Series is designed with user comfort and convenience in mind. The machines often come equipped with intuitive control panels and digital displays, which simplify the setup process and allow for precise adjustments. Newer models include features such as auto-set functionality that automatically adjusts the parameters for optimal welding performance based on the material thickness and type.

Safety is another critical area of focus for the Lincoln 1300 Series. Many models include built-in safety features such as over-temperature protection and low-voltage input capabilities. These enhancements ensure a safer working environment, minimizing the risk of accidents while maximizing operational efficiency.

In terms of durability, the construction of these machines is robust, often including metal chassis that can withstand tough working conditions. This rugged design contributes to the overall longevity of the equipment, making it a worthwhile investment for users who rely on their welding machines regularly.

In summary, the Lincoln 1300 Series stands out for its versatility, cutting-edge technology, user-friendly design, safety features, and durability. Whether you are a seasoned professional or a DIY enthusiast, these machines offer reliable performance suited for a wide range of welding applications, ensuring that you can achieve high-quality results with ease.