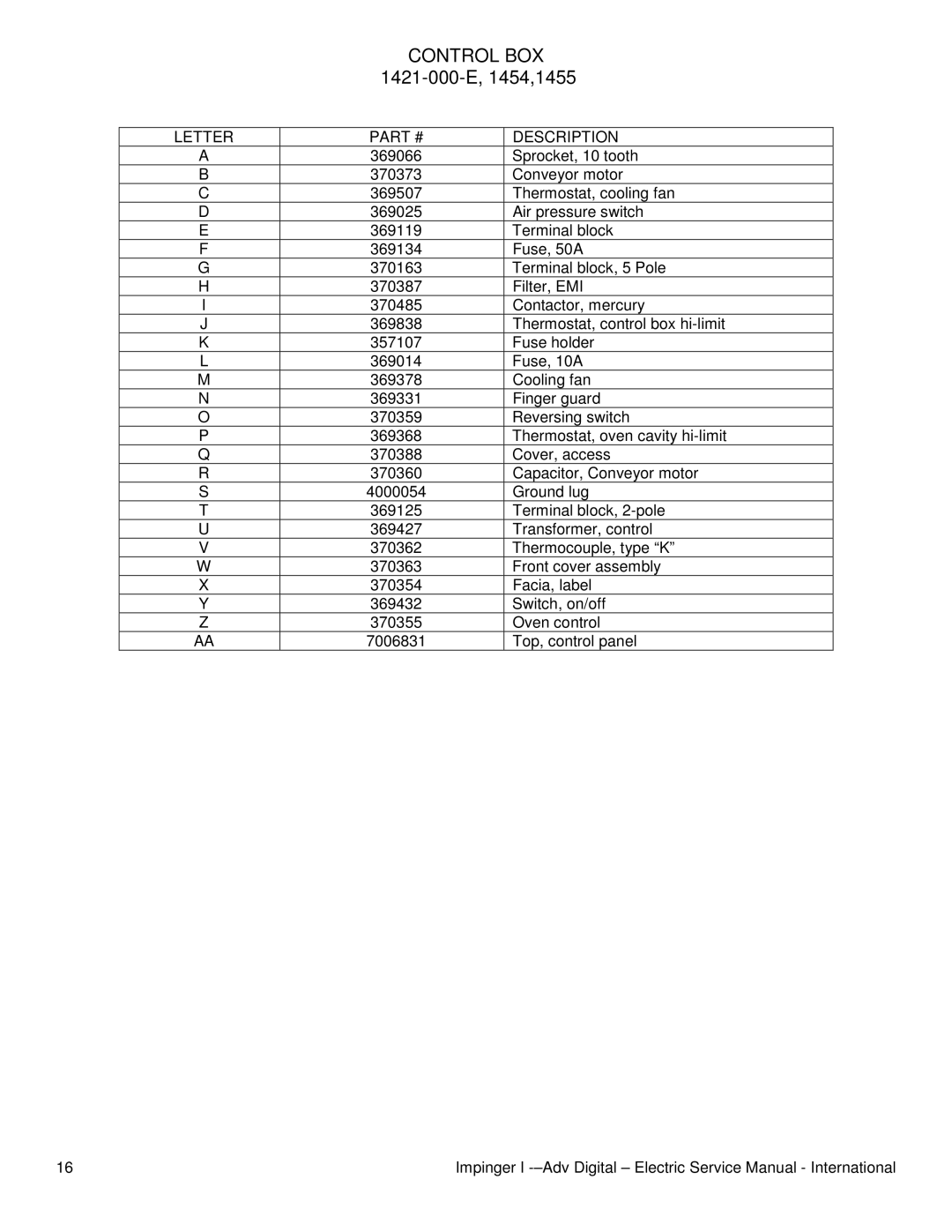

1454-000-E, 1455-000-E specifications

Lincoln 1455-000-E and 1454-000-E represent two cutting-edge welding machines that have been designed to meet the demanding needs of modern industrial environments. With their advanced features and robust technologies, they cater to a wide range of welding applications, making them an ideal choice for professionals seeking efficiency and reliability.The Lincoln 1455-000-E is equipped with a high-performance inverter technology, ensuring that it provides a stable and consistent arc. This feature significantly enhances the precision of welds, minimizing defects and ensuring high-quality outputs. The inverter system also lends itself to a more lightweight and compact design, making the machine easy to transport and maneuver, which is a crucial factor in many job sites.

On the other hand, the Lincoln 1454-000-E model focuses on versatility and adaptability. This machine supports multiple welding processes, including MIG, TIG, and stick welding, which allows users to switch between methods seamlessly based on their project demands. This flexibility is built upon a user-friendly control panel that simplifies process adjustments and settings, enabling welders of all skill levels to operate the machine efficiently.

Both models boast a robust construction, designed to withstand harsh working conditions typically found in industrial settings. They are equipped with thermal overload protection, which prevents damage and ensures longevity even during prolonged use. Additionally, these machines feature an integrated cooling system that enables extended operational periods without overheating.

Connectivity is another key feature of both models. They are designed with modern technological integration in mind, offering options for remote monitoring and control through dedicated software. This capability allows operators to track performance metrics in real-time and make necessary adjustments on the fly, optimizing their welding processes.

Furthermore, safety is a top priority in the design of the Lincoln 1455-000-E and 1454-000-E. Both machines come with built-in safety mechanisms, including voltage reduction features to protect the user from potential electrical hazards.

In conclusion, the Lincoln 1455-000-E and 1454-000-E are exemplary machines that combine advanced welding technologies with robust features, making them suitable for a variety of industrial applications. Their design emphasizes efficiency, ease of use, and safety, appealing to both professionals and novices in the welding industry.