10R specifications

Lincoln Electric 10R is a versatile and powerful welding machine designed to meet the demands of both industrial and commercial applications. As a prominent player in the welding industry, Lincoln Electric has consistently delivered quality and innovation, and the 10R model stands out as a testament to this commitment.One of the standout features of the Lincoln Electric 10R is its multi-process functionality. This machine supports MIG, TIG, and Stick welding processes, making it a truly compatible tool for various welding tasks. This versatility is vital for shops looking to optimize their workflow as it allows them to tackle diverse projects without needing multiple welders.

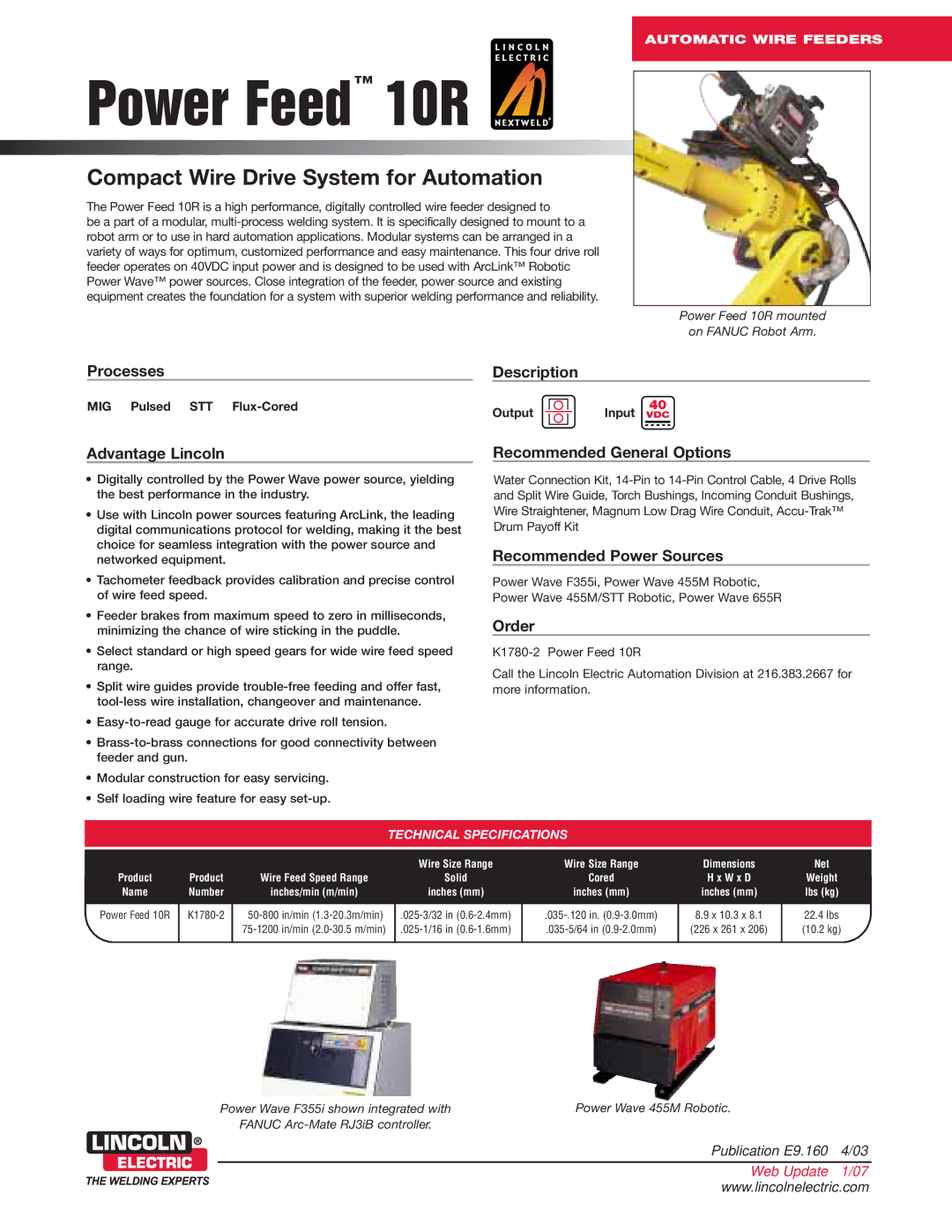

The 10R is equipped with Lincoln Electric's patented Power Feed system, which enhances the overall welding experience by ensuring consistent wire feeding. This is critical for achieving high-quality welds and minimizing defects. The system is designed for easy setup and adjustment, allowing welders to focus on their craft without getting bogged down by technical difficulties.

In addition to its robust feeding system, the Lincoln Electric 10R features advanced digital controls. These controls provide precise settings and allow for quick adjustments to welding parameters, resulting in better control over the welding process. The user-friendly interface ensures that even novice welders can operate the machine effectively while enabling seasoned professionals to maximize efficiency.

Durability is another characteristic that sets the 10R apart from its competitors. Constructed with heavy-duty materials, this machine is built to withstand the rigors of a busy workshop. The portable design, combined with a lightweight body, enhances its mobility, allowing users to transport it easily between job sites.

Safety is paramount in welding applications, and Lincoln Electric has integrated safety features into the 10R. These include thermal overload protection and voltage protection, which help to safeguard the machine and the user during operation. The inclusion of top-quality insulation and cooling systems further enhances the safety profile of this machine.

Overall, the Lincoln Electric 10R is a top-tier welding machine designed for professionals who value performance, reliability, and versatility. Its advanced features, including multi-process capability, smart controls, and superior durability, make it an invaluable asset for any welding operation. Whether you are working in fabrication, construction, or maintenance, the 10R provides the tools and technology to deliver exceptional results.