A CLOSER LOOK

PERFORMANCE

Arc Performance

•300 amps @100% duty cycle with output range up to 400 amps. All ratings are at temperatures of 104°F/40°C.

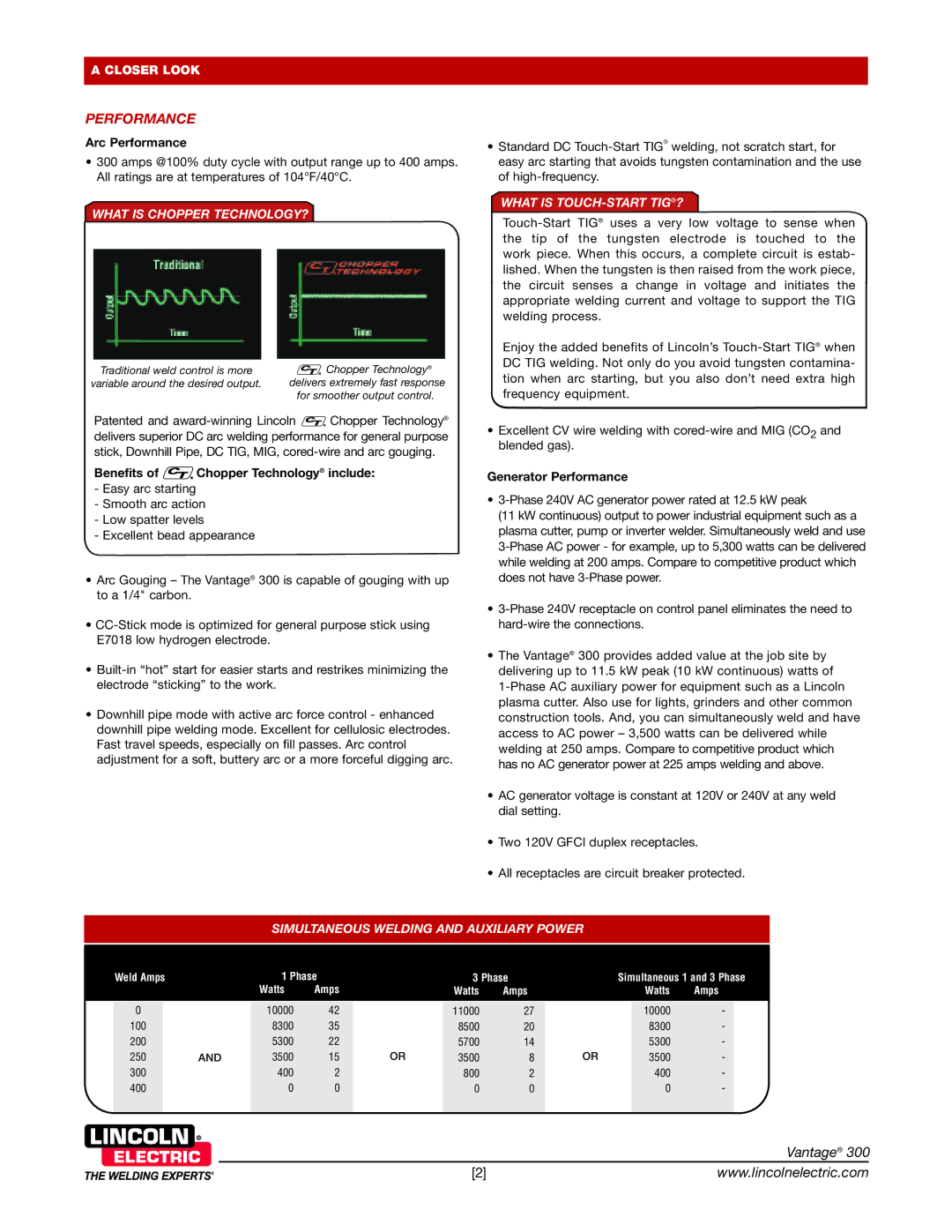

WHAT IS CHOPPER TECHNOLOGY?

Traditional weld control is more | Chopper Technology® |

variable around the desired output. | delivers extremely fast response |

| for smoother output control. |

Patented and ![]() Chopper Technology® delivers superior DC arc welding performancefor general purpose stick, Downhill Pipe, DC TIG, MIG,

Chopper Technology® delivers superior DC arc welding performancefor general purpose stick, Downhill Pipe, DC TIG, MIG,

Benefits of  Chopper Technology® include:

Chopper Technology® include:

-Easy arc starting

-Smooth arc action

-Low spatter levels

-Excellent bead appearance

•Arc Gouging – The Vantage® 300 is capable of gouging with up to a 1/4" carbon.

•

•

•Downhill pipe mode with active arc force control - enhanced downhill pipe welding mode. Excellent for cellulosic electrodes. Fast travel speeds, especially on fill passes. Arc control adjustment for a soft, buttery arc or a more forceful digging arc.

•Standard DC

WHAT IS TOUCH-START TIG®?

Enjoy the added benefits of Lincoln’s

•Excellent CV wire welding with

Generator Performance

•

(11 kW continuous)output to power industrialequipmentsuch as a plasma cutter,pump or inverterwelder.Simultaneouslyweld and use

•

•The Vantage® 300 provides added value at the job site by delivering up to 11.5 kW peak (10 kW continuous) watts of

•AC generator voltage is constant at 120V or 240V at any weld dial setting.

•Two 120V GFCI duplex receptacles.

•All receptacles are circuit breaker protected.

SIMULTANEOUSWELDING AND AUXILIARY POWER

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Weld Amps |

| 1 Phase |

|

| 3 Phase |

| Simultaneous 1 and 3 Phase | ||||||

|

|

|

|

| Watts | Amps |

| Watts | Amps |

|

| Watts | Amps | ||

|

| 0 |

|

| 10000 | 42 |

| 11000 | 27 |

|

| 10000 | - |

| |

|

| 100 |

|

| 8300 | 35 |

| 8500 | 20 |

|

| 8300 | - |

| |

|

| 200 |

|

| 5300 | 22 |

| 5700 | 14 |

|

| 5300 | - |

| |

|

| 250 |

| AND | 3500 | 15 | OR | 3500 | 8 | OR |

| 3500 | - |

| |

|

| 300 |

|

| 400 | 2 |

| 800 | 2 |

|

| 400 | - |

| |

|

| 400 |

|

| 0 | 0 |

| 0 | 0 |

|

| 0 | - |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Vantage® 300 |

[2] | www.lincolnelectric.com |