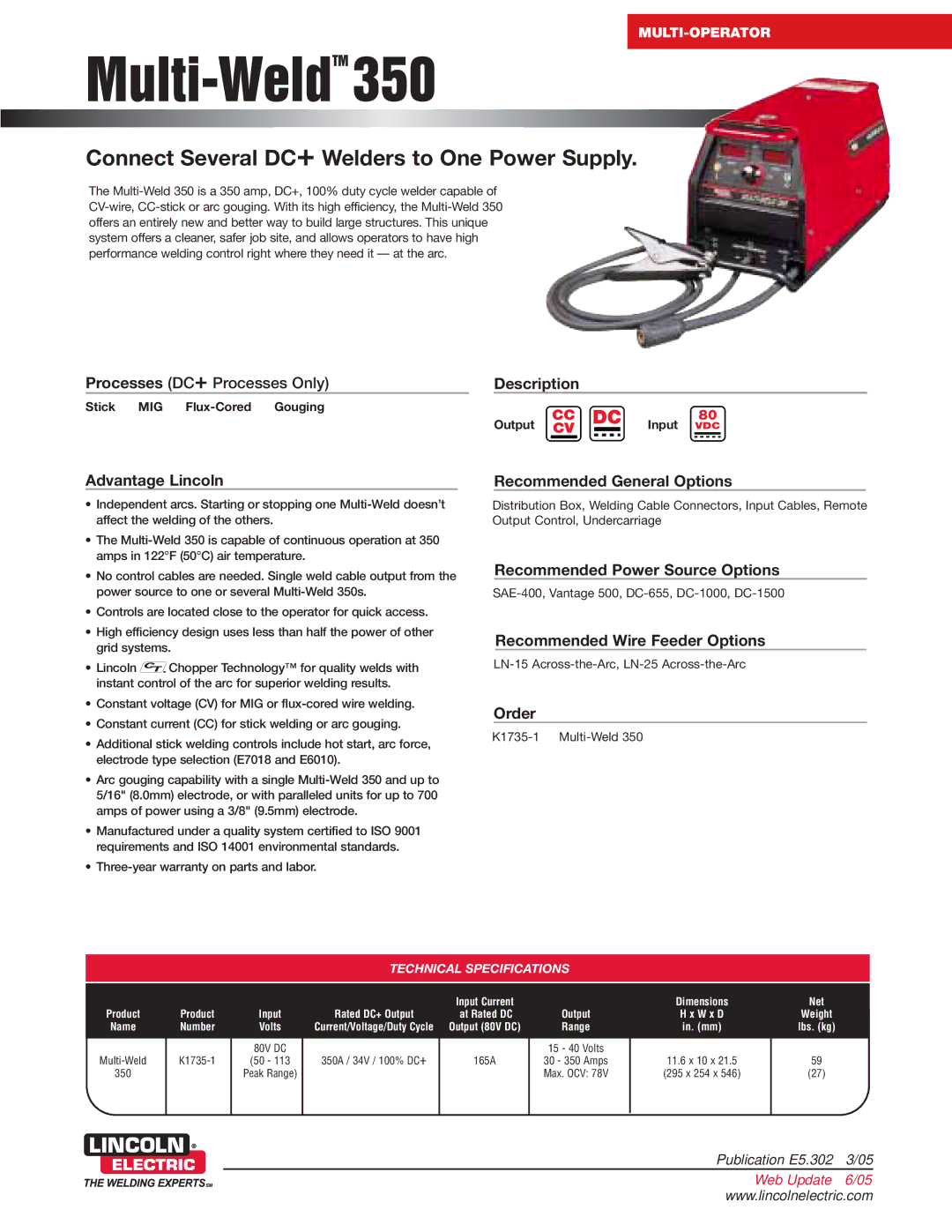

Multi-WeldTM 350

Connect Several DC+ Welders to One Power Supply.

The

Processes (DC+ Processes Only)

Stick MIG Flux-Cored Gouging

Advantage Lincoln

•Independent arcs. Starting or stopping one

•The

Description

80

Output |

| Input VDC | |||

|

|

|

|

|

|

|

|

|

|

|

|

Recommended General Options

Distribution Box, Welding Cable Connectors, Input Cables, Remote Output Control, Undercarriage

•No control cables are needed. Single weld cable output from the power source to one or several

•Controls are located close to the operator for quick access.

•High efficiency design uses less than half the power of other grid systems.

•Lincoln ![]()

![]() Chopper Technology™ for quality welds with instant control of the arc for superior welding results.

Chopper Technology™ for quality welds with instant control of the arc for superior welding results.

•Constant voltage (CV) for MIG or

•Constant current (CC) for stick welding or arc gouging.

•Additional stick welding controls include hot start, arc force, electrode type selection (E7018 and E6010).

•Arc gouging capability with a single

•Manufactured under a quality system certified to ISO 9001 requirements and ISO 14001 environmental standards.

•

Recommended Power Source Options

Recommended Wire Feeder Options

Order

TECHNICAL SPECIFICATIONS

Product

Name

350

Product Number

Input

Volts

80V DC

(50 - 113

Peak Range)

Input Current

Rated DC+ Output at Rated DC

Current/Voltage/Duty Cycle Output (80V DC)

350A / 34V / 100% DC+ | 165A |

|

|

Output

Range

15 - 40 Volts

30 - 350 Amps

Max. OCV: 78V

Dimensions

H x W x D

in. (mm)

11.6x 10 x 21.5 (295 x 254 x 546)

Net

Weight

lbs. (kg)

59

(27)

Publication E5.302 3/05

Web Update 6/05 www.lincolnelectric.com