A CLOSER LOOK

SUPERIOR WELDING PERFORMANCE

•Superior starting compliments the soft, stable welding arc yielding very low spatter levels. Chopper control has an extremely fast response for tighter output control than tradition weld control.

•High efficient design and low input current draw means more welding.

Chopper Technology | Chopper Technology | Traditional weld control is |

for extremely fast response | more variable around the | |

for smoother output control. |

| desired output. |

Traditional Reactor

Technology

CV-Wire Mode

Patented and ![]() Chopper Technology delivers superior DC arc welding performance for general purpose stick, Downhill Pipe, DC TIG, MIG,

Chopper Technology delivers superior DC arc welding performance for general purpose stick, Downhill Pipe, DC TIG, MIG,

Benefits of Chopper Technology include: - Easy arc starting

-Smooth arc action

-Low spatter levels

-Excellent bead appearance

FEATURES

•Each

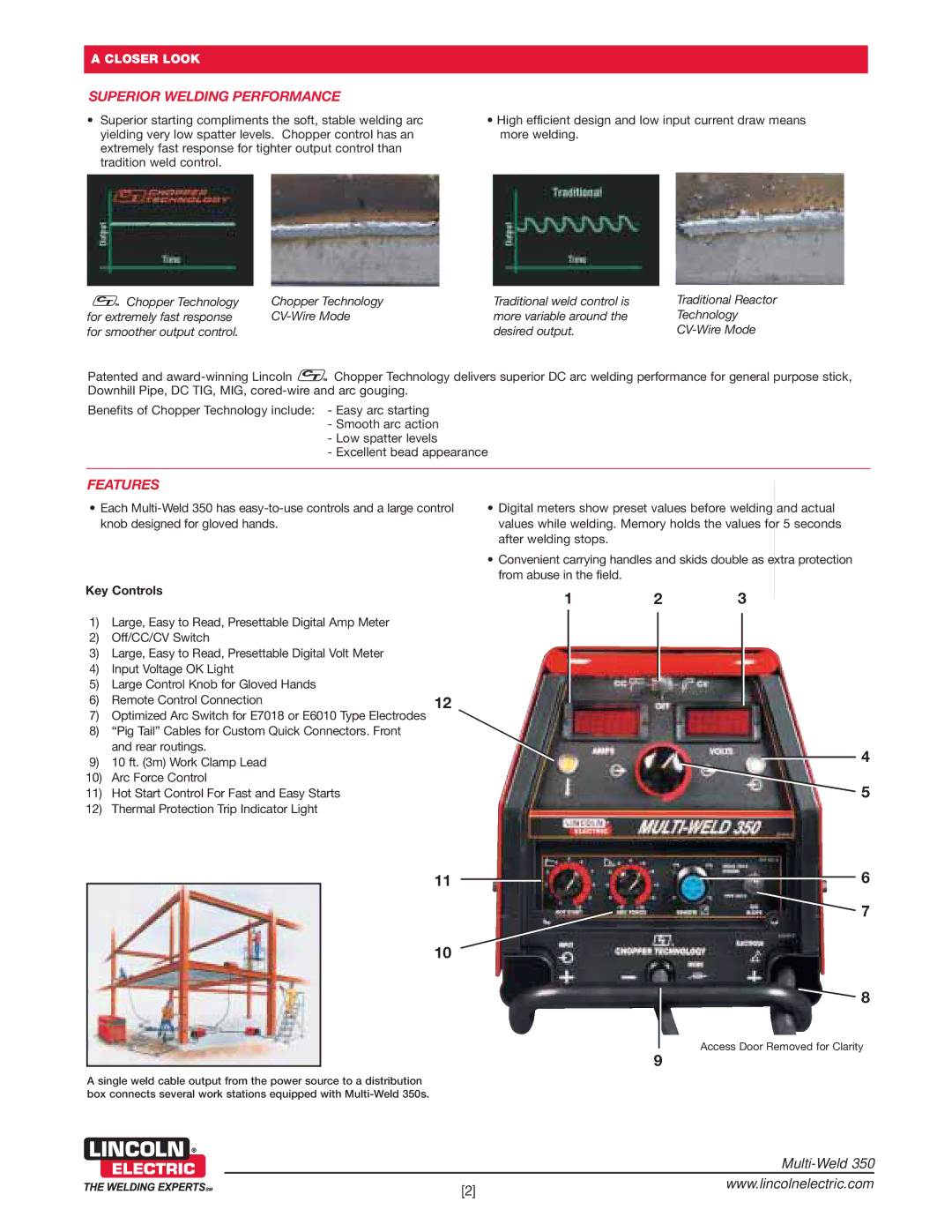

Key Controls

1)Large, Easy to Read, Presettable Digital Amp Meter

2)Off/CC/CV Switch

3)Large, Easy to Read, Presettable Digital Volt Meter

4)Input Voltage OK Light

5)Large Control Knob for Gloved Hands

6) Remote Control Connection | 12 |

7)Optimized Arc Switch for E7018 or E6010 Type Electrodes

8)“Pig Tail” Cables for Custom Quick Connectors. Front and rear routings.

9)10 ft. (3m) Work Clamp Lead

10)Arc Force Control

11)Hot Start Control For Fast and Easy Starts

12)Thermal Protection Trip Indicator Light

11

10

• Digital meters show preset values before welding and actual values while welding. Memory holds the values for 5 seconds after welding stops.

• Convenient carrying handles and skids double as extra protection from abuse in the field.

12 3

4

![]() 5

5

6 ![]() 7

7

![]() 8

8

Access Door Removed for Clarity

9

A single weld cable output from the power source to a distribution box connects several work stations equipped with

[2][2] | www.lincolnelectric.com |

|