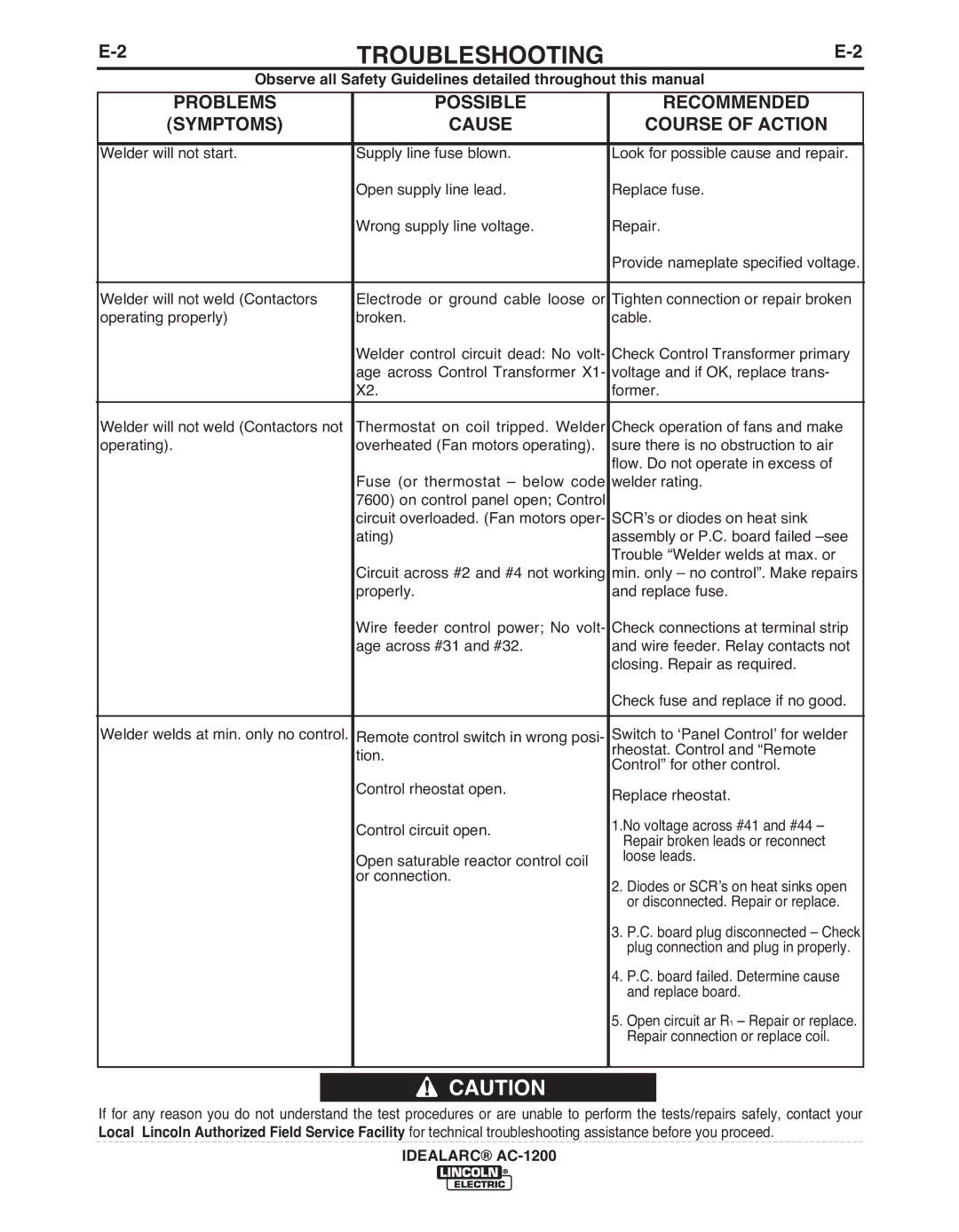

TROUbLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PRObLEMS

(SYMPTOMS)

POSSIbLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Welder will not start. | Supply line fuse blown. | Look for possible cause and repair. |

| Open supply line lead. | Replace fuse. |

| Wrong supply line voltage. | Repair. |

|

| Provide nameplate specified voltage. |

|

|

|

Welder will not weld (Contactors | Electrode or ground cable loose or | Tighten connection or repair broken |

operating properly) | broken. | cable. |

| Welder control circuit dead: No volt- | Check Control Transformer primary |

| age across Control Transformer X1- | voltage and if OK, replace trans- |

| X2. | former. |

|

|

|

Welder will not weld (Contactors not | Thermostat on coil tripped. Welder | Check operation of fans and make |

operating). | overheated (Fan motors operating). | sure there is no obstruction to air |

|

| flow. Do not operate in excess of |

| Fuse (or thermostat – below code | welder rating. |

| 7600) on control panel open; Control |

|

| circuit overloaded. (Fan motors oper- | SCR’s or diodes on heat sink |

| ating) | assembly or P.C. board failed |

|

| Trouble “Welder welds at max. or |

| Circuit across #2 and #4 not working | min. only – no control”. Make repairs |

| properly. | and replace fuse. |

| Wire feeder control power; No volt- | Check connections at terminal strip |

| age across #31 and #32. | and wire feeder. Relay contacts not |

|

| closing. Repair as required. |

|

| Check fuse and replace if no good. |

|

|

|

Welder welds at min. only no control. | Remote control switch in wrong posi- | Switch to ‘Panel Control’ for welder |

| tion. | rheostat. Control and “Remote |

| Control” for other control. | |

|

| |

| Control rheostat open. | Replace rheostat. |

|

| |

| Control circuit open. | 1.No voltage across #41 and #44 – |

| Repair broken leads or reconnect | |

|

| |

| Open saturable reactor control coil | loose leads. |

|

| |

| or connection. | 2. Diodes or SCR’s on heat sinks open |

|

| |

|

| or disconnected. Repair or replace. |

|

| 3. P.C. board plug disconnected – Check |

|

| plug connection and plug in properly. |

|

| 4. P.C. board failed. Determine cause |

|

| and replace board. |

|

| 5. Open circuit ar R1 – Repair or replace. |

|

| Repair connection or replace coil. |

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

IDEALARC®