DC -1000 specifications

The Lincoln Electric DC-1000 is a powerful and versatile industrial welding power source known for its reliability and performance in various welding applications. As a flagship model in Lincoln Electric’s line of welding equipment, the DC-1000 combines advanced features and technologies to cater to the needs of professional welders in demanding environments.At the heart of the DC-1000 are its robust electrical characteristics. The machine delivers a constant current output, making it suitable for various welding processes, including Stick, TIG, and MIG. The output range of the DC-1000 is impressive, providing the ability to weld materials with thicknesses ranging from thin sheets to heavy plates. This flexibility allows operators to use the power source for various applications, from fabrication to maintenance and repair tasks.

One of the key technologies found in the DC-1000 is the use of inverter technology. This innovation enhances the efficiency of the power source by converting input power into direct current more effectively. This results in improved arc stability and a higher duty cycle, allowing for longer periods of operation without overheating or downtime. The machine also features adjustable arc control, enabling welders to fine-tune the arc characteristics for different materials and welding techniques.

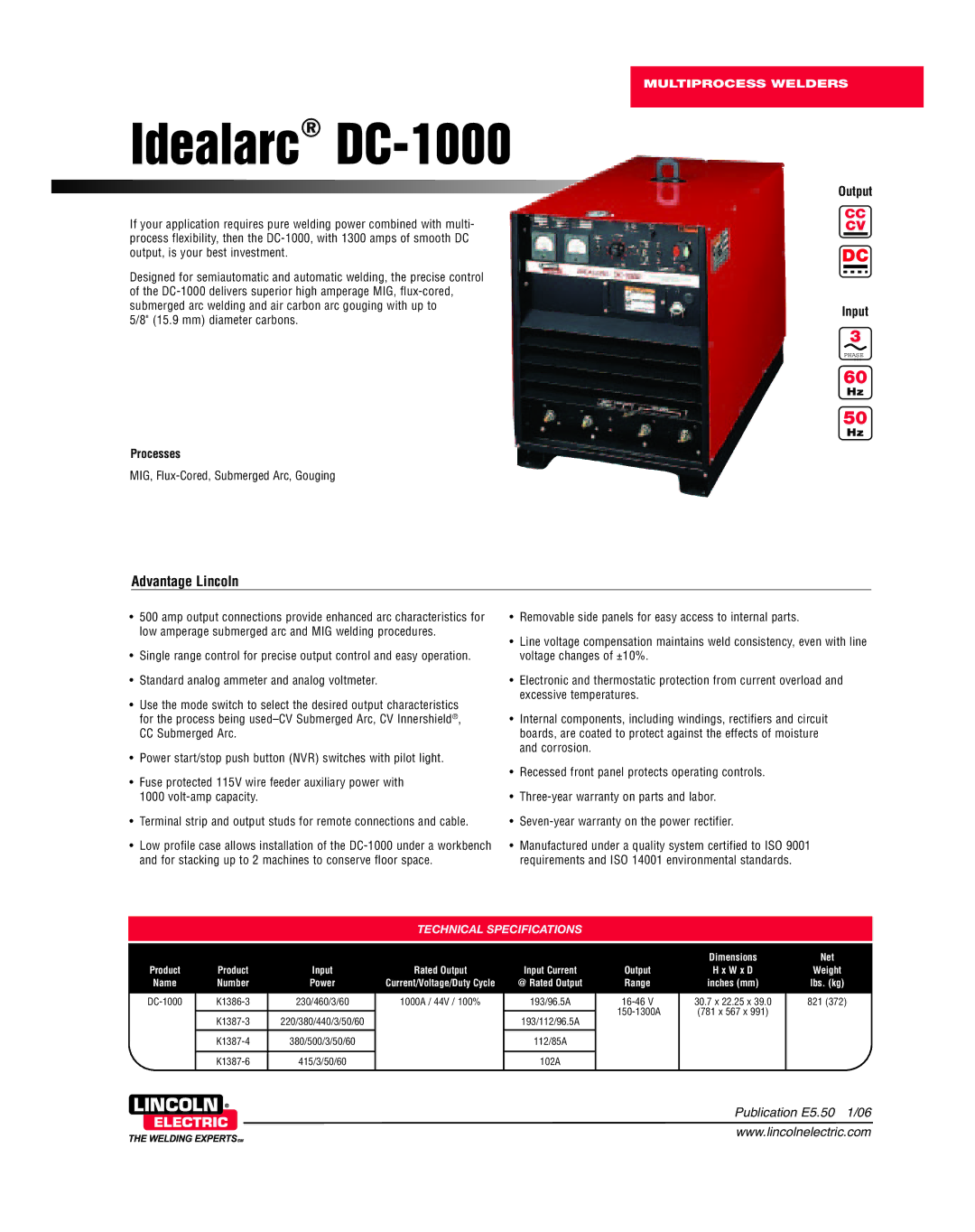

The DC-1000 is designed with a user-friendly interface that includes easy-to-read ammeter and voltmeter displays. This makes it simple for welders to monitor their settings and adjustments during operation. Furthermore, the machine’s sturdy construction ensures durability, making it suitable for use in harsh industrial environments.

Portability is another essential characteristic of the Lincoln Electric DC-1000. Despite its impressive power output, the unit is designed to be easily transportable, featuring a compact design and integrated handles. This allows welders to move the machine to different job sites with ease, enhancing productivity.

In summary, the Lincoln Electric DC-1000 is a cutting-edge welding power source that excels in versatility, efficiency, and ease of use. With its constant current output, inverter technology, and user-friendly features, it caters to the diverse needs of professional welders, making it a top choice for industrial applications. Whether used in heavy fabrication or repair work, the DC-1000 is built to deliver consistent performance and reliability.