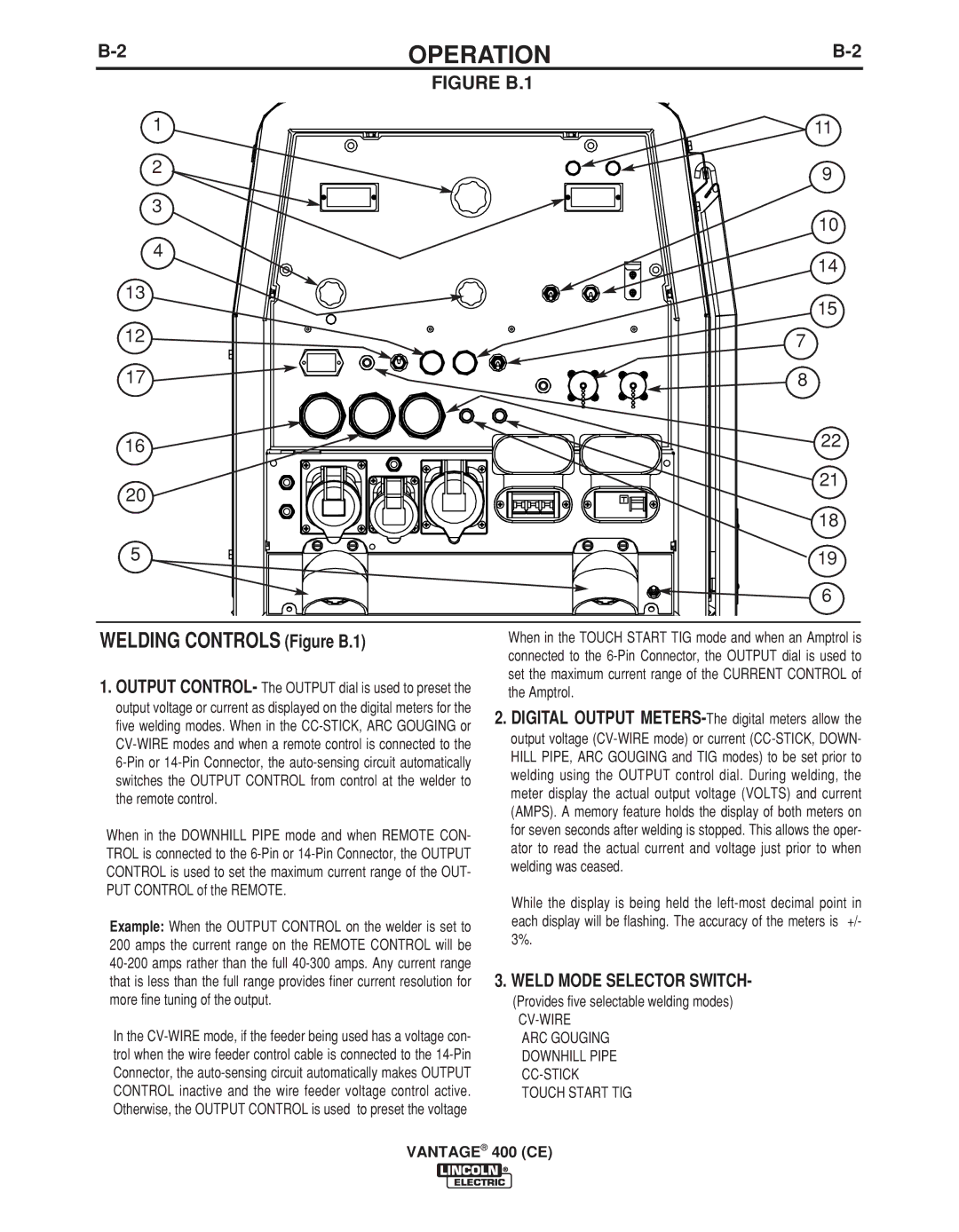

WELDING CONTROLS (Figure B.1)

1.OUTPUT CONTROL- The OUTPUT dial is used to preset the output voltage or current as displayed on the digital meters for the five welding modes. When in the CC-STICK, ARC GOUGING or CV-WIRE modes and when a remote control is connected to the 6-Pin or 14-Pin Connector, the auto-sensing circuit automatically switches the OUTPUT CONTROL from control at the welder to the remote control.

When in the DOWNHILL PIPE mode and when REMOTE CON- TROL is connected to the 6-Pin or 14-Pin Connector, the OUTPUT CONTROL is used to set the maximum current range of the OUT- PUT CONTROL of the REMOTE.

Example: When the OUTPUT CONTROL on the welder is set to 200 amps the current range on the REMOTE CONTROL will be 40-200 amps rather than the full 40-300 amps. Any current range that is less than the full range provides finer current resolution for more fine tuning of the output.

In the CV-WIRE mode, if the feeder being used has a voltage con- trol when the wire feeder control cable is connected to the 14-Pin Connector, the auto-sensing circuit automatically makes OUTPUT CONTROL inactive and the wire feeder voltage control active. Otherwise, the OUTPUT CONTROL is used to preset the voltage

When in the TOUCH START TIG mode and when an Amptrol is connected to the 6-Pin Connector, the OUTPUT dial is used to set the maximum current range of the CURRENT CONTROL of the Amptrol.

2.DIGITAL OUTPUT METERS-The digital meters allow the output voltage (CV-WIRE mode) or current (CC-STICK, DOWN- HILL PIPE, ARC GOUGING and TIG modes) to be set prior to welding using the OUTPUT control dial. During welding, the meter display the actual output voltage (VOLTS) and current (AMPS). A memory feature holds the display of both meters on for seven seconds after welding is stopped. This allows the oper- ator to read the actual current and voltage just prior to when welding was ceased.

While the display is being held the left-most decimal point in each display will be flashing. The accuracy of the meters is +/- 3%.

3.WELD MODE SELECTOR SWITCH-

(Provides five selectable welding modes)

CV-WIRE

ARC GOUGING DOWNHILL PIPE CC-STICK TOUCH START TIG