OPERATION | ||

|

|

|

2.WIRE FEED SPEED KNOb

The large, calibrated wire feed speed knob makes for easy and accurate adjustment of the wire feed speed. The knob rotates 3/4 turn. Turn the knob clockwise to increase the wire feed speed, and counter clockwise to reduce the wire feed speed.

Models with analog voltmeters have a calibrated scale printed around the wire feed speed knob using "in/min" units. A separate decal with "m/min" units is included with these models wire feeder.

Wire Feed Speed, CV Operation

When Across the Arc models are operated with CV power sources, the wire feed speed will remain a con- stant value, independent of arc voltage changes, as along as the arc voltage does not drop below the val- ues per the following table.

| CV OPERATION |

| |

|

|

| |

Minimum Arc Volts | Maximum WFS | Maximum WFS | |

|

| Standard Spin | (Extra Torque |

|

| Gearing | Gearing) |

15 V |

| 280 | 210 |

17 V |

| 340 | 235 |

21 V |

| 440 | 400 |

24 V |

| 520 | 400 |

27 V |

| 600 | 400 |

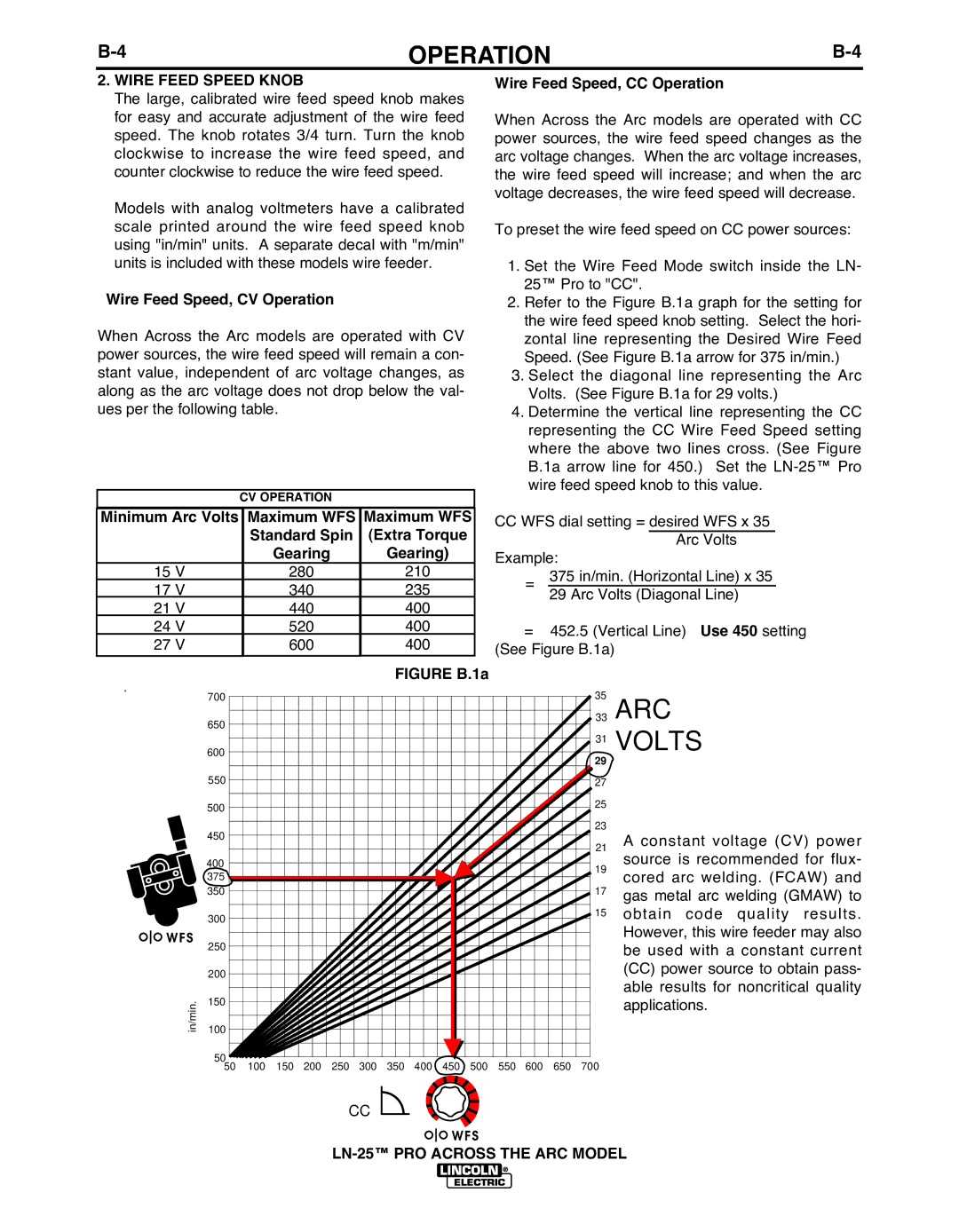

FIGURE b.1a

Wire Feed Speed, CC Operation

When Across the Arc models are operated with CC power sources, the wire feed speed changes as the arc voltage changes. When the arc voltage increases, the wire feed speed will increase; and when the arc voltage decreases, the wire feed speed will decrease.

To preset the wire feed speed on CC power sources:

1.Set the Wire Feed Mode switch inside the LN- 25™ Pro to "CC".

2.Refer to the Figure B.1a graph for the setting for the wire feed speed knob setting. Select the hori- zontal line representing the Desired Wire Feed Speed. (See Figure B.1a arrow for 375 in/min.)

3.Select the diagonal line representing the Arc Volts. (See Figure B.1a for 29 volts.)

4.Determine the vertical line representing the CC representing the CC Wire Feed Speed setting where the above two lines cross. (See Figure B.1a arrow line for 450.) Set the

CCWFS dial setting = desired WFS x 35

Arc Volts

Example:

=375 in/min. (Horizontal Line) x 35

29 Arc Volts (Diagonal Line)

= 452.5 (Vertical Line) Use 450 setting (See Figure B.1a)

700

650

600

550

500

450

3533 ARC

31VOLTS

29

27

25

23

21A constant voltage (CV) power

400

375

19

source is recommended for flux- cored arc welding. (FCAW) and

in/min.

350

300

250

200

150

100

50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 |

50 |

17gas metal arc welding (GMAW) to

15obtain code quality results. However, this wire feeder may also be used with a constant current

(CC)power source to obtain pass- able results for noncritical quality applications.

550 600 650 700

CC ![]()