OPERATION |

PRODUCT DESCRIPTION

The new COOL ARC® 35 is an intelligent cooling unit equipped with a variable speed three phase rotary pump and an embedded microprocessor PC board which controls the pump operation, fan operation, and the overall functioning of the unit.

The cooler operation is enabled by the power source and utilizes a “cool as needed” approach, so the pump and fan speed vary based on real coolant tempera- ture. Furthermore, error signals and related codes are managed by the power source.

The COOL ARC® 35 manages both the coolant tem- perature and pressure in order to maximize the cool- ing of the torch, while using as little energy as possi- ble. If the coolant temperature goes above the maxi- mum limit 185°F (85°C) or the coolant flow is stopped or the coolant is missing, an alarm is generated and an error code is sent to the power source. The power source, consequently, displays the alarm ID code on the user interface and places the power source and cooler in a safe condition in order to avoid any dam- age being done to the cooling components or to the welding torch. Any alarm condition must be reset by the user by clearing the alarm code at the power source user interface before restarting operation, oth- erwise; the overall welding system is kept in a standby condition (safety mode).

If a coolant over temperature is detected, welding is stopped and the cooler is programmed to run at maxi- mum speed in order to recover from the high tempera- ture condition as soon as possible. Welding operation cannot be re¬started before the coolant temperature has reached a temperature value below 175°F (80°C).

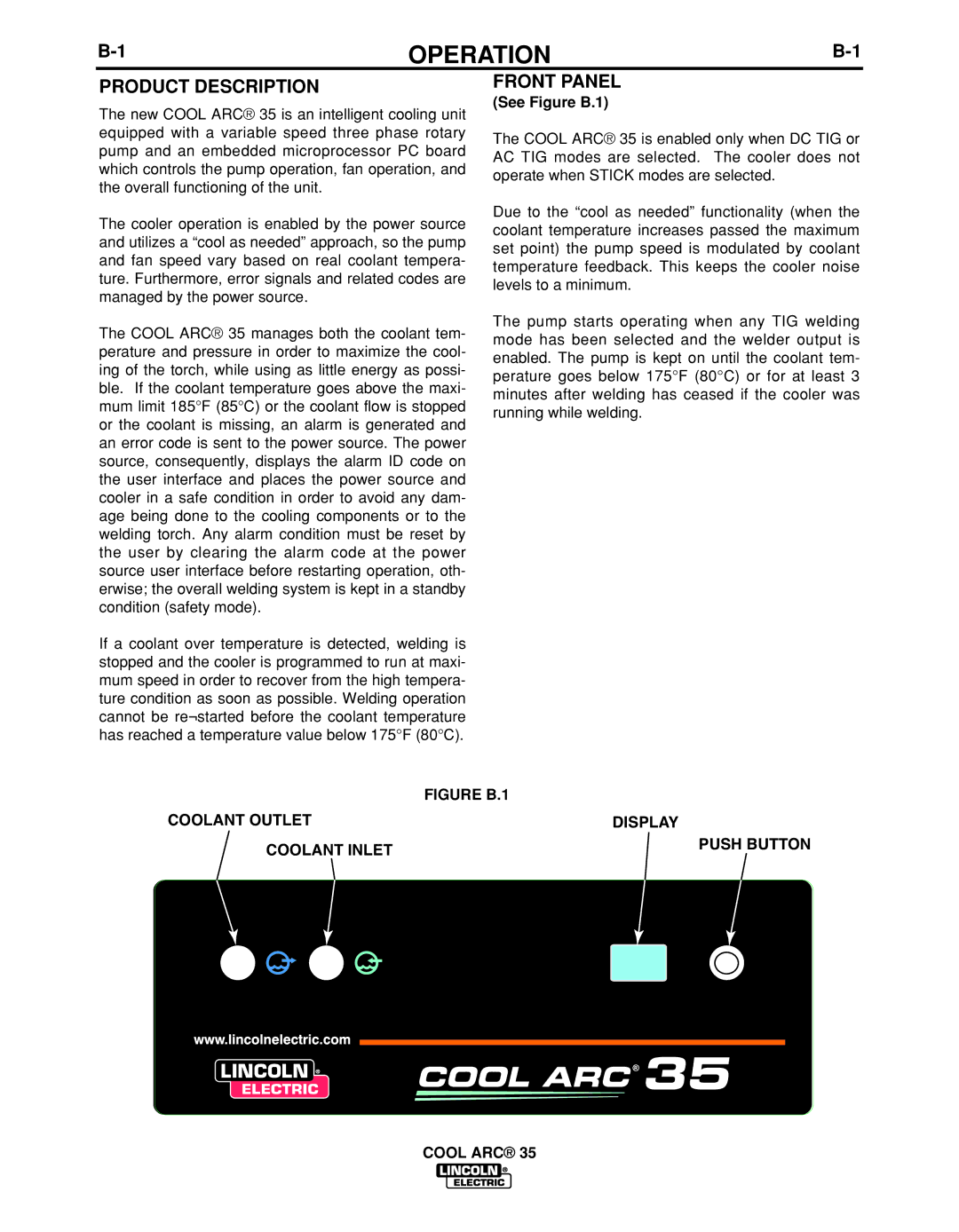

FRONT PANEL

(See Figure B.1)

The COOL ARC® 35 is enabled only when DC TIG or AC TIG modes are selected. The cooler does not operate when STICK modes are selected.

Due to the “cool as needed” functionality (when the coolant temperature increases passed the maximum set point) the pump speed is modulated by coolant temperature feedback. This keeps the cooler noise levels to a minimum.

The pump starts operating when any TIG welding mode has been selected and the welder output is enabled. The pump is kept on until the coolant tem- perature goes below 175°F (80°C) or for at least 3 minutes after welding has ceased if the cooler was running while welding.

| FIGURE B.1 |

COOLANT OUTLET | DISPLAY |

COOLANT INLET | PUSH BUTTON |

COOL ARC® 35