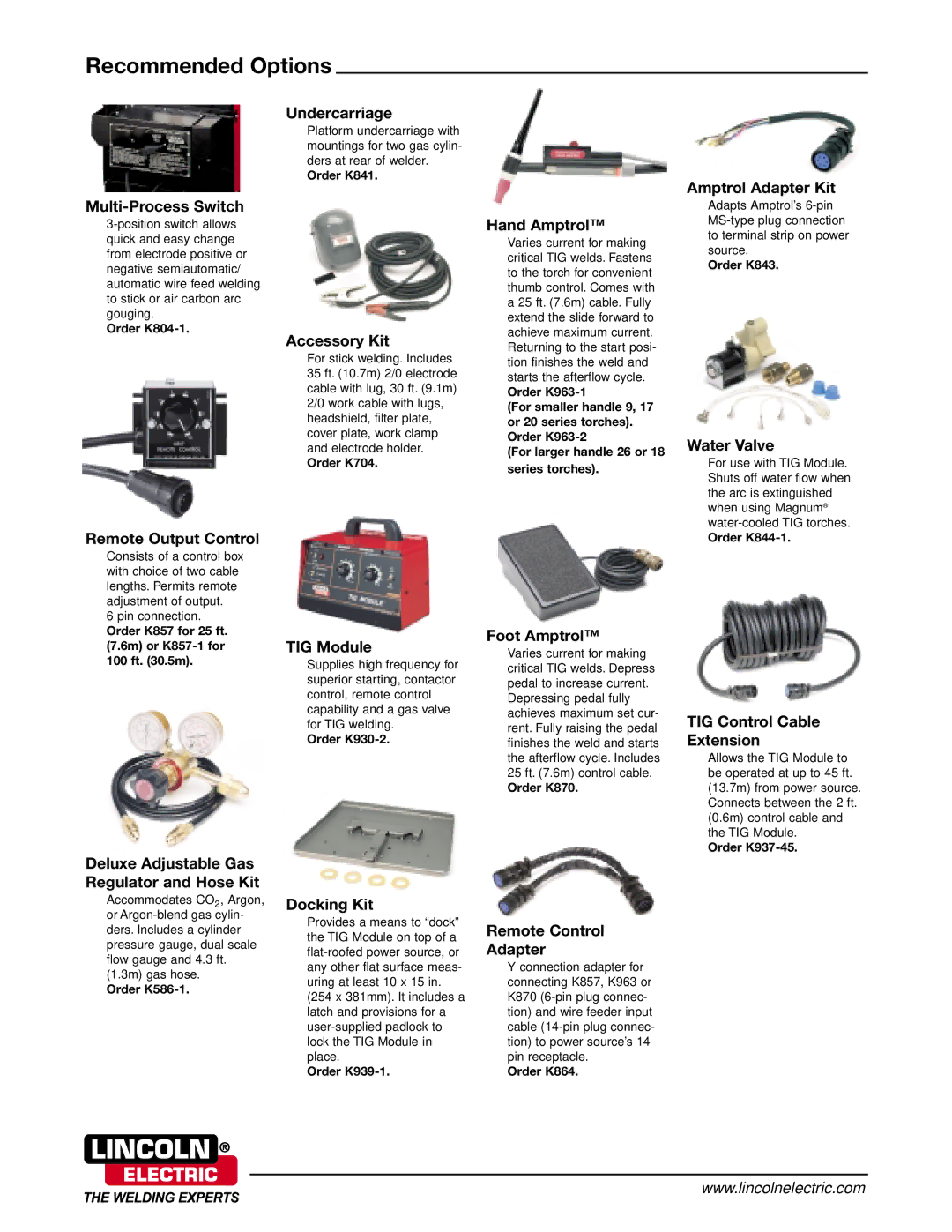

Recommended Options

Undercarriage

Platform undercarriage with mountings for two gas cylin- ders at rear of welder.

Order K841.

Multi-Process Switch

Order

Accessory Kit

For stick welding. Includes 35 ft. (10.7m) 2/0 electrode cable with lug, 30 ft. (9.1m) 2/0 work cable with lugs, headshield, filter plate, cover plate, work clamp and electrode holder.

Order K704.

Hand Amptrol™

Varies current for making critical TIG welds. Fastens to the torch for convenient thumb control. Comes with a 25 ft. (7.6m) cable. Fully extend the slide forward to achieve maximum current. Returning to the start posi- tion finishes the weld and starts the afterflow cycle.

Order

(For smaller handle 9, 17 or 20 series torches). Order

(For larger handle 26 or 18 series torches).

Amptrol Adapter Kit

Adapts Amptrol’s

Order K843.

Water Valve

For use with TIG Module. Shuts off water flow when the arc is extinguished when using Magnum®

Remote Output Control

Consists of a control box with choice of two cable lengths. Permits remote adjustment of output.

6 pin connection.

Order K857 for 25 ft. (7.6m) or

TIG Module

Supplies high frequency for superior starting, contactor control, remote control capability and a gas valve for TIG welding.

Order

Foot Amptrol™

Varies current for making critical TIG welds. Depress pedal to increase current. Depressing pedal fully achieves maximum set cur- rent. Fully raising the pedal finishes the weld and starts the afterflow cycle. Includes 25 ft. (7.6m) control cable.

Order K870.

Order

TIG Control Cable Extension

Allows the TIG Module to be operated at up to 45 ft. (13.7m) from power source. Connects between the 2 ft. (0.6m) control cable and the TIG Module.

Order

Deluxe Adjustable Gas Regulator and Hose Kit

Accommodates CO2, Argon, or

(1.3m) gas hose.

Order

Docking Kit

Provides a means to “dock” | Remote Control | |

the TIG Module on top of a | ||

Adapter | ||

any other flat surface meas- | Y connection adapter for | |

uring at least 10 x 15 in. | connecting K857, K963 or | |

(254 x 381mm). It includes a | K870 | |

latch and provisions for a | tion) and wire feeder input | |

cable | ||

lock the TIG Module in | tion) to power source’s 14 | |

place. | pin receptacle. | |

Order | Order K864. |

[3] | www.lincolnelectric.com |