A CLOSER LOOK

Weightand Design

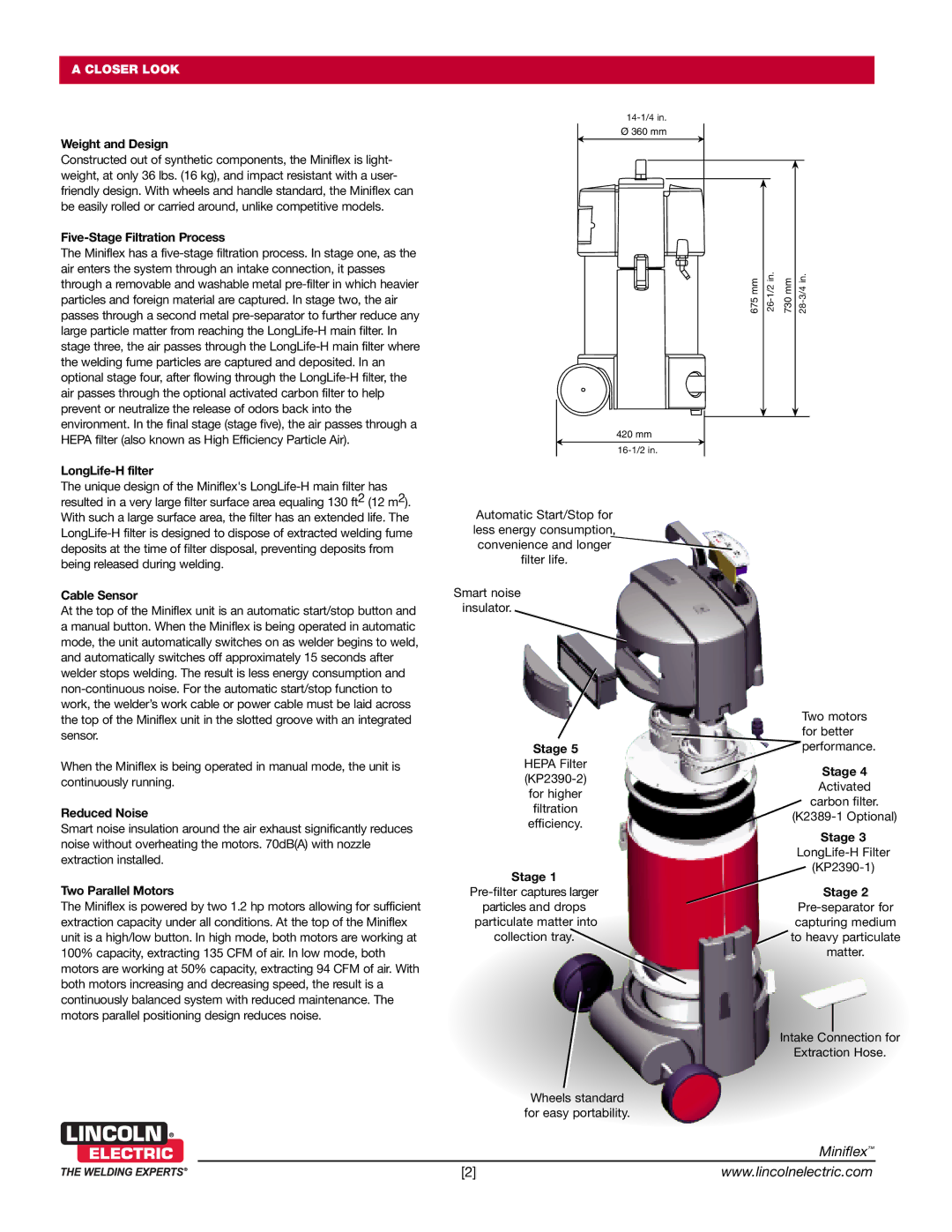

Constructedout of syntheticcomponents,the Miniflexis light- weight,at only 36 lbs. (16 kg), and impact resistantwith a user- friendlydesign. With wheels and handle standard,the Miniflexcan be easily rolledor carriedaround,unlike competitivemodels.

Five-StageFiltrationProcess

The Miniflexhas a

LongLife-Hfilter

Ø 360 mm

675 mm |

| 730 mm | ||

| ||||

|

|

|

|

|

420 mm

The unique design of the

Cable Sensor

At the top of the Miniflexunit is an automaticstart/stopbutton and

amanual button. When the Miniflexis being operatedin automatic mode, the unit automaticallyswitcheson as welder begins to weld, and automaticallyswitchesoff approximately15 secondsafter welder stops welding.The resultis less energyconsumptionand

When the Miniflexis being operatedin manual mode, the unit is continuouslyrunning.

ReducedNoise

Smart noise insulationaroundthe air exhaustsignificantlyreduces noise withoutoverheatingthe motors. 70dB(A)with nozzle extractioninstalled.

TwoParallelMotors

The Miniflexis poweredby two 1.2 hp motors allowingfor sufficient extractioncapacityunder all conditions.At the top of the Miniflex unit is a high/lowbutton. In high mode, both motors are workingat 100% capacity,extracting135 CFM of air.In low mode, both motors are workingat 50% capacity,extracting94 CFM of air.With both motors increasingand decreasingspeed, the resultis a continuouslybalancedsystem with reducedmaintenance.The motors parallelpositioningdesign reducesnoise.

Automatic Start/Stop for less energy consumption, convenience and longer![]() filter life.

filter life.

Smart noise insulator.

Stage 5

HEPA Filter

Stage 1

Wheels standard for easy portability.

Two motors for better performance.

Stage 4

Activated carbon filter.

Stage 3

Stage 2

![]() to heavy particulate

to heavy particulate

matter.

Intake Connection for

Extraction Hose.

Miniflex™

[2] | www.lincolnelectric.com |