V350-PRO specifications

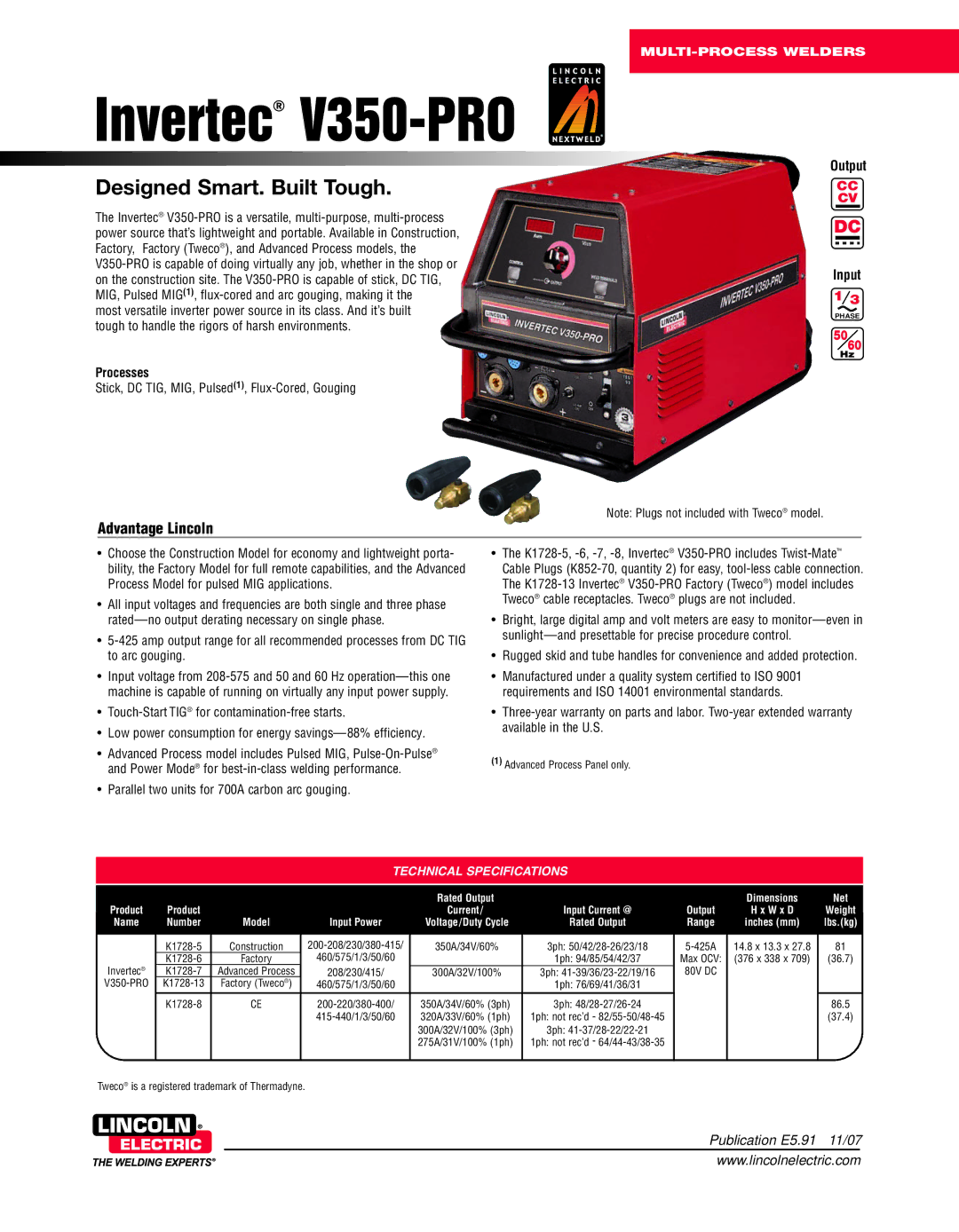

The Lincoln Electric V350-PRO is a versatile and high-performance multi-process welding machine designed for professionals who demand reliability and precision in their work. Known for its robust design and advanced features, the V350-PRO stands out in the competitive field of welding solutions.One of the primary features of the V350-PRO is its ability to perform multiple welding processes, including MIG, TIG, and Stick welding. This multi-process capability makes it an ideal choice for a wide range of applications, from light fabrication to heavy industrial welding. The machine operates on both 220V and 480V power sources, allowing for flexibility and adaptability in different environments.

The V350-PRO is equipped with Lincoln Electric's patented Auto-Set technology. This innovative feature automatically adjusts the machine settings based on the materials being welded, significantly reducing setup time and allowing welders to focus on their craft. The user-friendly interface, complete with an intuitive digital display, allows welders to easily monitor settings and output parameters.

Another standout characteristic of the V350-PRO is its Output Control Technology, which provides the welder with precise control over the voltage and wire feed speed. The machine offers a wide output range, allowing for adjustments that cater to various thicknesses of material and welding positions. This flexibility ensures high-quality welds with minimal spatter, making it perfect for delicate tasks as well as heavy-duty projects.

The machine's durable construction ensures longevity and reliability, even in the most demanding working conditions. The V350-PRO features a rugged enclosure that protects its internal components from dust and moisture, promoting consistent performance over time. Additionally, it is designed with portability in mind, featuring a lightweight frame and ergonomic handles for easy transportation to job sites.

Safety is a priority with the V350-PRO, which includes built-in protection features such as thermal overload protection, ensuring the machine operates within safe limits. This attention to safety, coupled with its advanced technology and user-friendly design, makes the Lincoln Electric V350-PRO a preferred choice for professionals who seek efficiency and quality in their welding processes.

In summary, the Lincoln Electric V350-PRO is a powerful and versatile welding machine that combines advanced technology with user-friendly features. Its multi-process capability, Auto-Set technology, and robust design make it a reliable solution for welders across various industries. Whether you are working on small projects or large-scale industrial applications, the V350-PRO delivers exceptional performance and quality welds, ensuring that your work is always up to the highest standards.