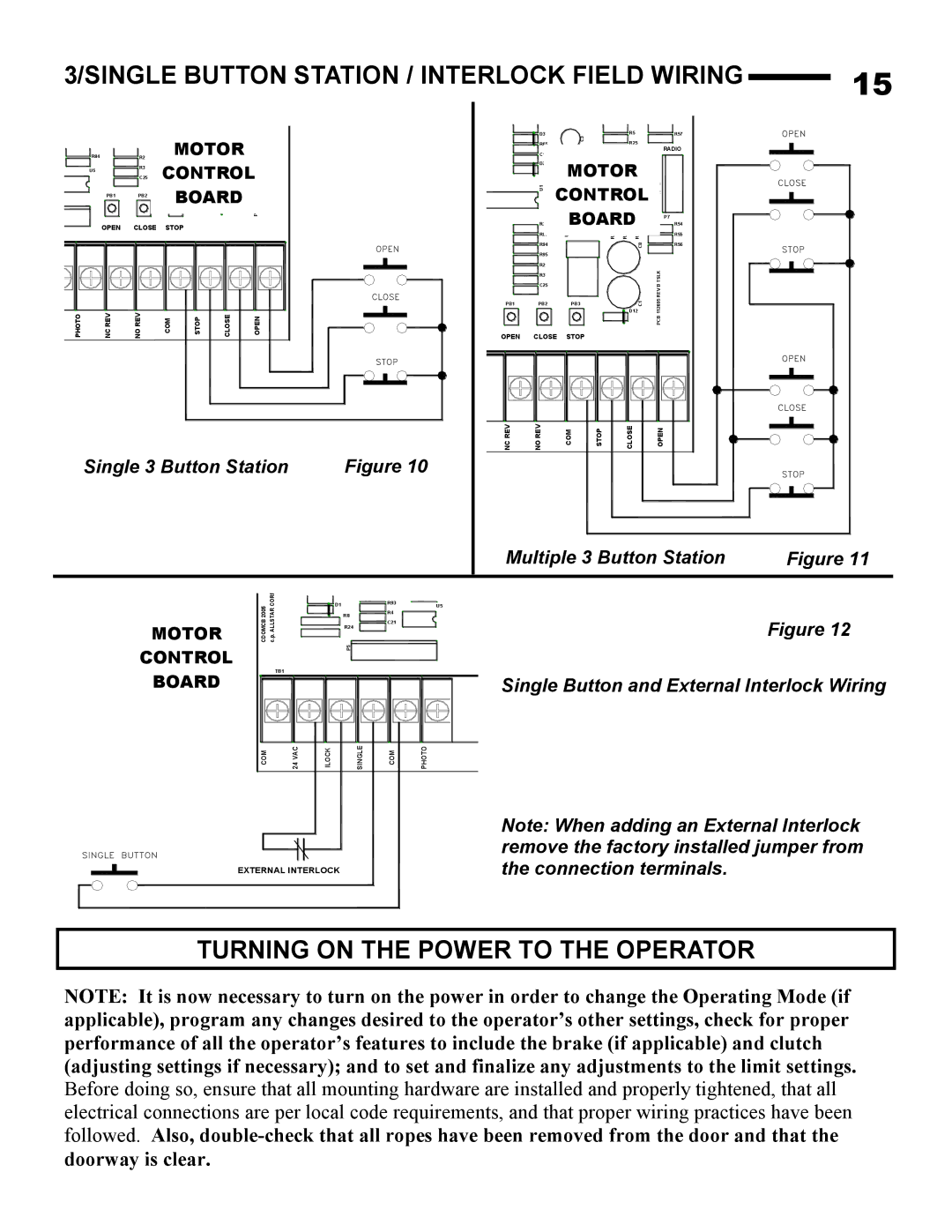

3/SINGLE BUTTON STATION / INTERLOCK FIELD WIRING |

| 15 |

| ||

| ||

|

|

|

|

|

|

| MOTOR |

|

|

|

|

|

| D3 | C3 |

| R5 | R57 |

| |

|

|

|

|

|

|

|

|

|

|

|

| R25 | RADIO |

| |||

|

|

|

|

|

|

|

|

|

| R65 |

|

|

| ||||

| R84 | R2 | CONTROL |

|

|

|

|

|

| MOTOR |

|

| |||||

| U5 | C25 |

|

|

|

|

| D2 |

|

| |||||||

|

| R3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PB1 | PB2 |

| BOARD |

|

|

|

|

|

| U1 | CONTROL |

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| BOARD | P7 |

| ||

| OPEN | CLOSE STOP |

|

|

|

|

|

|

|

|

|

|

| R54 |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

| R87 |

|

|

| R55 |

|

|

|

|

|

|

|

|

|

|

|

|

| R94 |

|

| C8 | R56 |

|

|

|

|

|

|

|

|

|

|

|

|

| R95 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| R2 |

|

|

| TSLKB |

|

|

|

|

|

|

|

|

|

|

|

|

| C25 |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| R3 |

|

|

|

|

|

PHOTO | REVNC | REVNO | COM | STOP | CLOSE | OPEN |

|

|

|

|

|

|

|

|

| REV |

|

|

|

|

| PB1 | PB2 | PB3 |

| C1 | 112695PCB |

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| D12 |

|

|

|

|

|

|

|

|

|

|

|

|

| OPEN | CLOSE STOP |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| NC REV | NO REV | COM | STOP | CLOSE | OPEN |

|

| Single 3 Button Station |

| Figure 10 |

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

| CORP.ALLSTARc.p. |

|

|

| Multiple 3 Button Station | Figure 11 | |||||

|

|

|

|

|

| 2005CDOMCB | D1 |

| R93 | U5 |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| R8 | R4 |

|

|

|

|

|

|

|

|

|

| MOTOR |

|

|

|

|

|

|

|

|

|

|

| Figure 12 | ||

|

|

|

|

|

|

|

| C21 |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| R24 |

|

|

|

|

|

|

|

|

|

| CONTROL |

|

|

| P5 |

|

|

|

|

|

|

|

| |||

|

|

| BOARD |

|

| TB1 |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| Single Button and External Interlock Wiring | ||||||||

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

| COM | 24 VAC | ILOCK | SINGLE | COM | PHOTO |

|

|

|

|

|

|

EXTERNAL INTERLOCK

Note: When adding an External Interlock remove the factory installed jumper from the connection terminals.

TURNING ON THE POWER TO THE OPERATOR

NOTE: It is now necessary to turn on the power in order to change the Operating Mode (if applicable), program any changes desired to the operator’s other settings, check for proper performance of all the operator’s features to include the brake (if applicable) and clutch (adjusting settings if necessary); and to set and finalize any adjustments to the limit settings. Before doing so, ensure that all mounting hardware are installed and properly tightened, that all electrical connections are per local code requirements, and that proper wiring practices have been followed. Also,