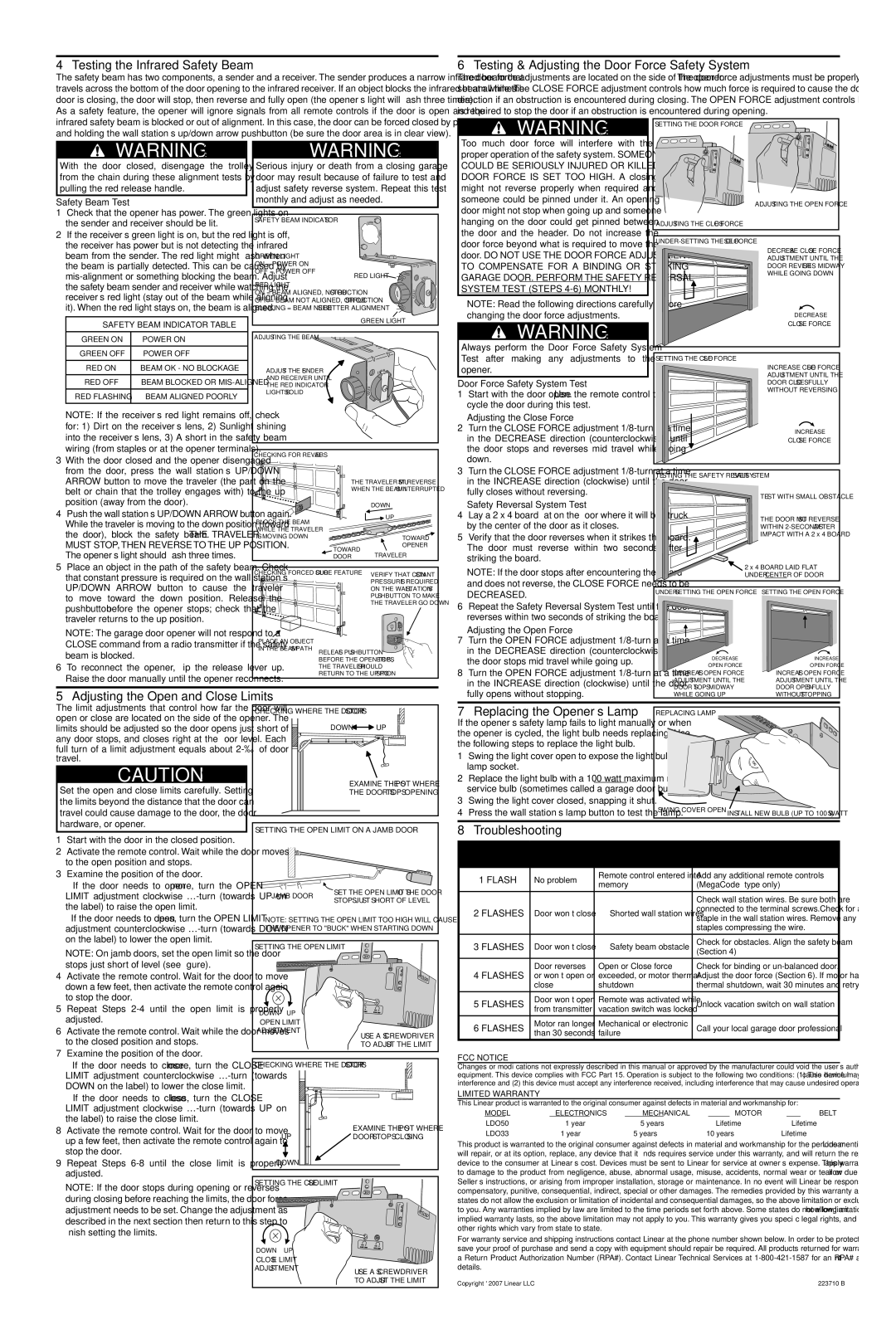

The limit adjustments that control how far the door will open or close are located on the side of the opener. The limits should be adjusted so the door opens just short of any door stops, and closes right at the fl oor level. Each

full turn of a limit adjustment equals about 2-½” of door travel.

CAUTION

Set the open and close limits carefully. Setting the limits beyond the distance that the door can travel could cause damage to the door, the door hardware, or opener.

1Start with the door in the closed position.

2Activate the remote control. Wait while the door moves to the open position and stops.

3Examine the position of the door.

•If the door needs to open more, turn the OPEN LIMIT adjustment clockwise ¼-turn (towards UP on the label) to raise the open limit.

•If the door needs to open less, turn the OPEN LIMIT adjustment counterclockwise ¼-turn (towards DOWN on the label) to lower the open limit.

➤NOTE: On jamb doors, set the open limit so the door stops just short of level (see figure).

4Activate the remote control. Wait for the door to move down a few feet, then activate the remote control again to stop the door.

5Repeat Steps 2-4 until the open limit is properly adjusted.

6Activate the remote control. Wait while the door moves to the closed position and stops.

7Examine the position of the door.

•If the door needs to close more, turn the CLOSE LIMIT adjustment counterclockwise ¼-turn (towards DOWN on the label) to lower the close limit.

•If the door needs to close less, turn the CLOSE LIMIT adjustment clockwise ¼-turn (towards UP on the label) to raise the close limit.

8Activate the remote control. Wait for the door to move up a few feet, then activate the remote control again to stop the door.

9Repeat Steps 6-8 until the close limit is properly adjusted.

➤NOTE: If the door stops during opening or reverses during closing before reaching the limits, the door force adjustment needs to be set. Change the adjustment as described in the next section then return to this step to finish setting the limits.

7 | Replacing the Opener’s Lamp | REPLACING LAMP | |

If the opener’s safety lamp fails to light manually or when | | |

the opener is cycled, the light bulb needs replacing. Use | | |

the following steps to replace the light bulb. | | |

1 | Swing the light cover open to expose the light bulb and | | |

| lamp socket. | | |

2 | Replace the light bulb with a 100 watt maximum rough | | |

| service bulb (sometimes called a garage door bulb). | | |

3 | Swing the light cover closed, snapping it shut. | | |

4 | Press the wall station’s lamp button to test the lamp. | SWING COVER OPEN | INSTALL NEW BULB (UP TO 100 WATTS) |

|

8 Troubleshooting

| LAMP FLASHES | PROBLEM | CAUSE | REMEDY |

| TROUBLE CODE |

| | | |

| | | | |

| 1 FLASH | No problem | Remote control entered into | Add any additional remote controls |

| memory | (MegaCode™ type only) |

| | |

| | | | |

| | | | Check wall station wires. Be sure both are |

| 2 FLASHES | Door won’t close | Shorted wall station wires | connected to the terminal screws.Check for a |

| staple in the wall station wires. Remove any |

| | | |

| | | | staples compressing the wire. |

| | | | |

| 3 FLASHES | Door won’t close | Safety beam obstacle | Check for obstacles. Align the safety beam |

| (Section 4) |

| | | |

| | | | |

| 4 FLASHES | Door reverses | Open or Close force | Check for binding or un-balanced door. |

| or won’t open or | exceeded, or motor thermal | Adjust the door force (Section 6). If motor had |

| | close | shutdown | thermal shutdown, wait 30 minutes and retry. |

| | | | |

| 5 FLASHES | Door won’t open | Remote was activated while | Unlock vacation switch on wall station |

| from transmitter | vacation switch was locked |

| | |

| | | | |

| 6 FLASHES | Motor ran longer | Mechanical or electronic | Call your local garage door professional |

| than 30 seconds | failure |

| | |

| | | | |

FCC NOTICE

Changes or modifi cations not expressly described in this manual or approved by the manufacturer could void the user’s authority to operate the equipment. This device complies with FCC Part 15. Operation is subject to the following two conditions: (1) This device may not cause harmful interference and (2) this device must accept any interference received, including interference that may cause undesired operation.

LIMITED WARRANTY

This Linear product is warranted to the original consumer against defects in material and workmanship for:

MODEL | ELECTRONICS | MECHANICAL | MOTOR | BELT |

LDO50 | 1 year | 5 years | Lifetime | Lifetime |

LDO33 | 1 year | 5 years | 10 years | Lifetime |

This product is warranted to the original consumer against defects in material and workmanship for the periods mentioned above. Linear will repair, or at its option, replace, any device that it fi nds requires service under this warranty, and will return the repaired or replaced device to the consumer at Linear’s cost. Devices must be sent to Linear for service at owner’s expense. This warranty does not apply to damage to the product from negligence, abuse, abnormal usage, misuse, accidents, normal wear or tear or due to failure to follow Seller’s instructions, or arising from improper installation, storage or maintenance. In no event will Linear be responsible for incidental, compensatory, punitive, consequential, indirect, special or other damages. The remedies provided by this warranty are exclusive. Some states do not allow the exclusion or limitation of incidental and consequential damages, so the above limitation or exclusion may not apply to you. Any warranties implied by law are limited to the time periods set forth above. Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. This warranty gives you specifi c legal rights, and you may also have other rights which vary from state to state.

For warranty service and shipping instructions contact Linear at the phone number shown below. In order to be protected by this warranty, save your proof of purchase and send a copy with equipment should repair be required. All products returned for warranty service require a Return Product Authorization Number (RPA#). Contact Linear Technical Services at 1-800-421-1587 for an RPA# and other important details.

Copyright © 2007 Linear LLC | 223710 B |