Speed change

To change the tool speed, turn the speed change knob so that the arrow of the de- sired speed on the knob is aligned with the reference arrow on the tool body. If the speed change knob does not turn easily, switch on the tool and turn the knob again while the tool is running under no load.

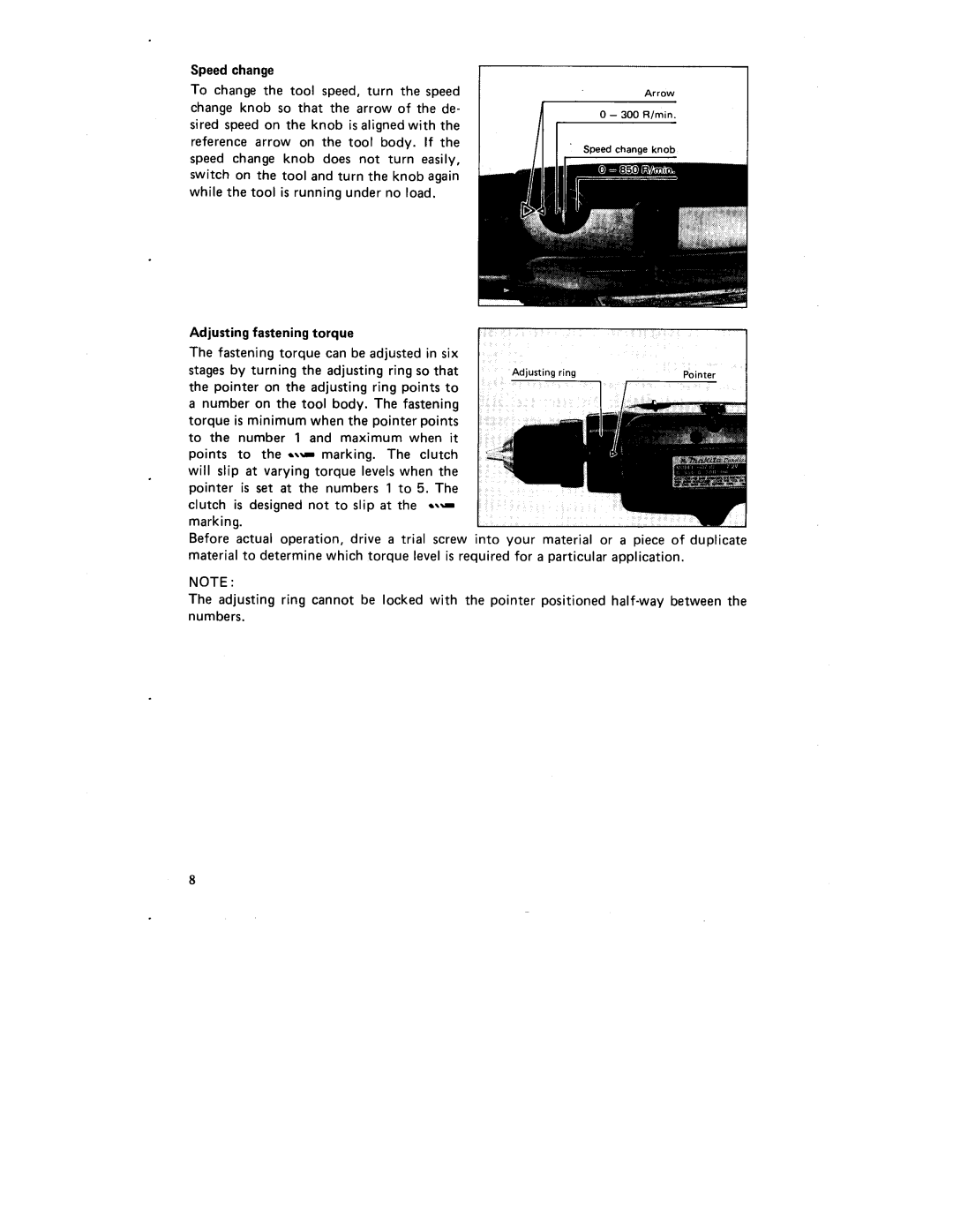

Adjusting fastening torque

The fastening torque can be adjusted in six stages by turning the adjusting ring so that the pointer on the adjusting ring points to a number on the tool body. The fastening torque is minimum when the pointer points to the number 1 and maximum when it points to the a\- marking. The clutch will slip at varying torque levels when the pointer is set at the numbers 1 to 5. The clutch is designed not to slip at the at- marking.

Before

NOTE :

The adjusting ring cannot be locked with the pointer num bers.

8

Arrow

material or a piece of duplicate a particular application.

positioned