Drilling operat ion

0 Drilling in wood

When drilling in wood, best results are obtained with wood drills equipped with a guide screw. The guide screw makes drilling easier by pulling the bit into the workpiece.

0 Drilling in metal

To prevent the bit from slipping when starting a hole, make an indentation with a center- punch and hammer at the point to be drilled. Place the point of the bit in the indenta- tion and start drilling.

Use a cutting lubricant when drilling metals. The exceptions are iron and brass which should be drilled dry.

CAUTION :

*Pressing excessively on the tool will not speed up the drilling. In fact, this excessive pres- sure will only serve to damage the tip of your bit, decrease the tool performance and shorten the service life of the tool.

*There is a tremendous force exerted on the tool/bit at the time of hole breakthrough. Hold the tool firmly and exert care when the bit begins to break through the workpiece.

0 A stuck bit can be removed simply by setting the reversing switch to reverse rotation in order to back out. However, the tool may back out abruptly if you do not hold it firmly.

0 Always secure small workpieces in a vise or similar

Screwdriving operation

Place the point of the driver bit in the screw head and apply pressure to the tool. Start the tool. Release the switch trigger just as the screw bottoms out. The electric brake will then stop the tool immediately, preventing the screw and/or bit from being damaged.

NOTE :

*Make sure that the driver bit is inserted straight in the screw head, or the screw and/or bit may be damaged.

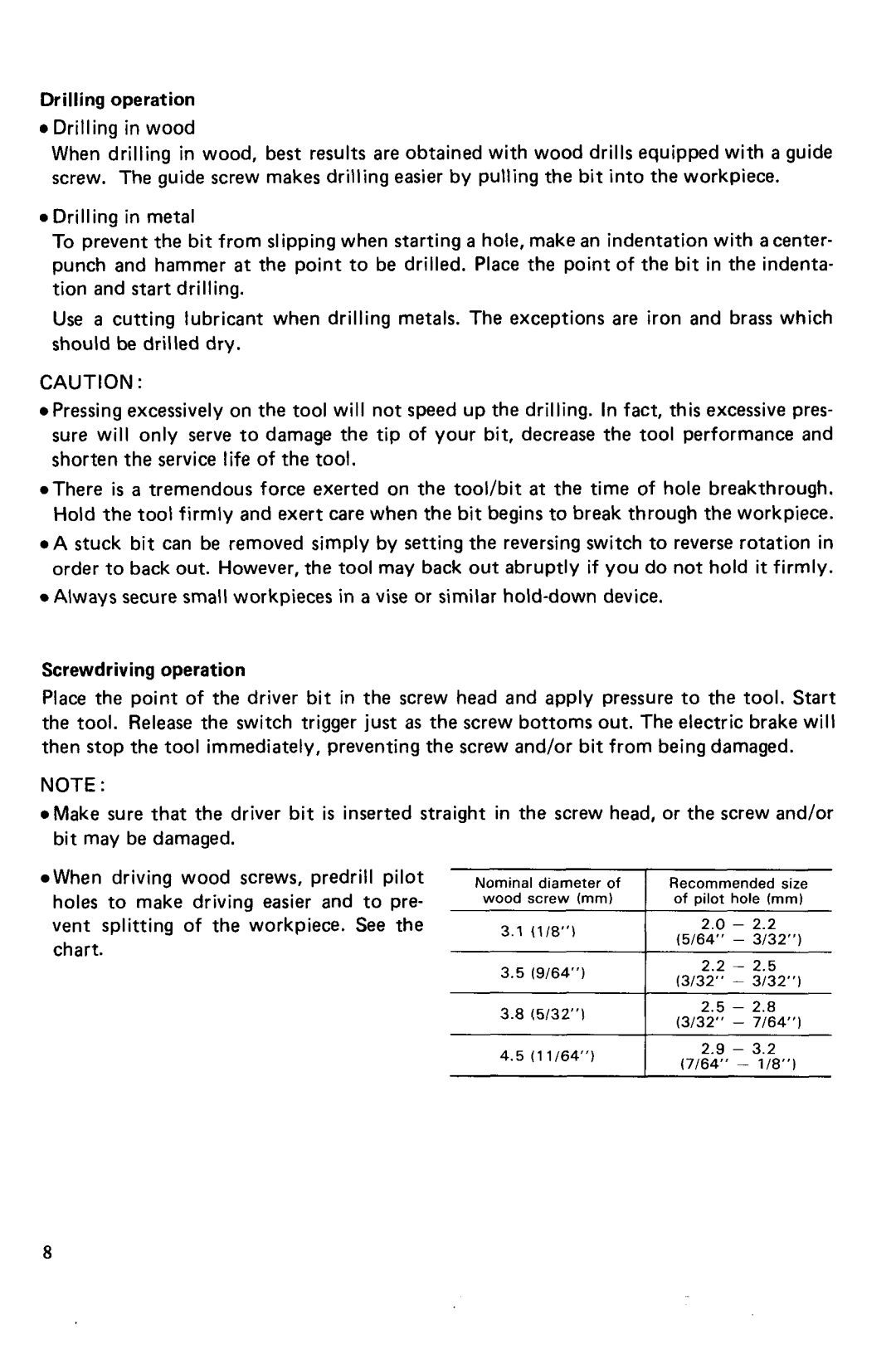

![]() When driving wood screws, predrill pilot holes to make driving easier and to pre- vent splitting of the workpiece. See the chart.

When driving wood screws, predrill pilot holes to make driving easier and to pre- vent splitting of the workpiece. See the chart.

Nominal diameter of wood screw (mm)

3.1(118“l 3.5 (9/64”) 3.8 (5132”)

4 . 5 ( 1 1/64”]

I

1

I

Recommended size of Dilot hole 1mml

2 . 0 - 2.2 (5/64,, - 3/32,,)

2.2 - 2.5 13/32” - 3/32”)

2.5 - 2.8 13/32,,- 7,64,,1

2.9 - 3.2 17/64,,- 1/8,,1

8