TOOL INSTALLATION INSTRUCTIONS AND US€

Selecting compressor

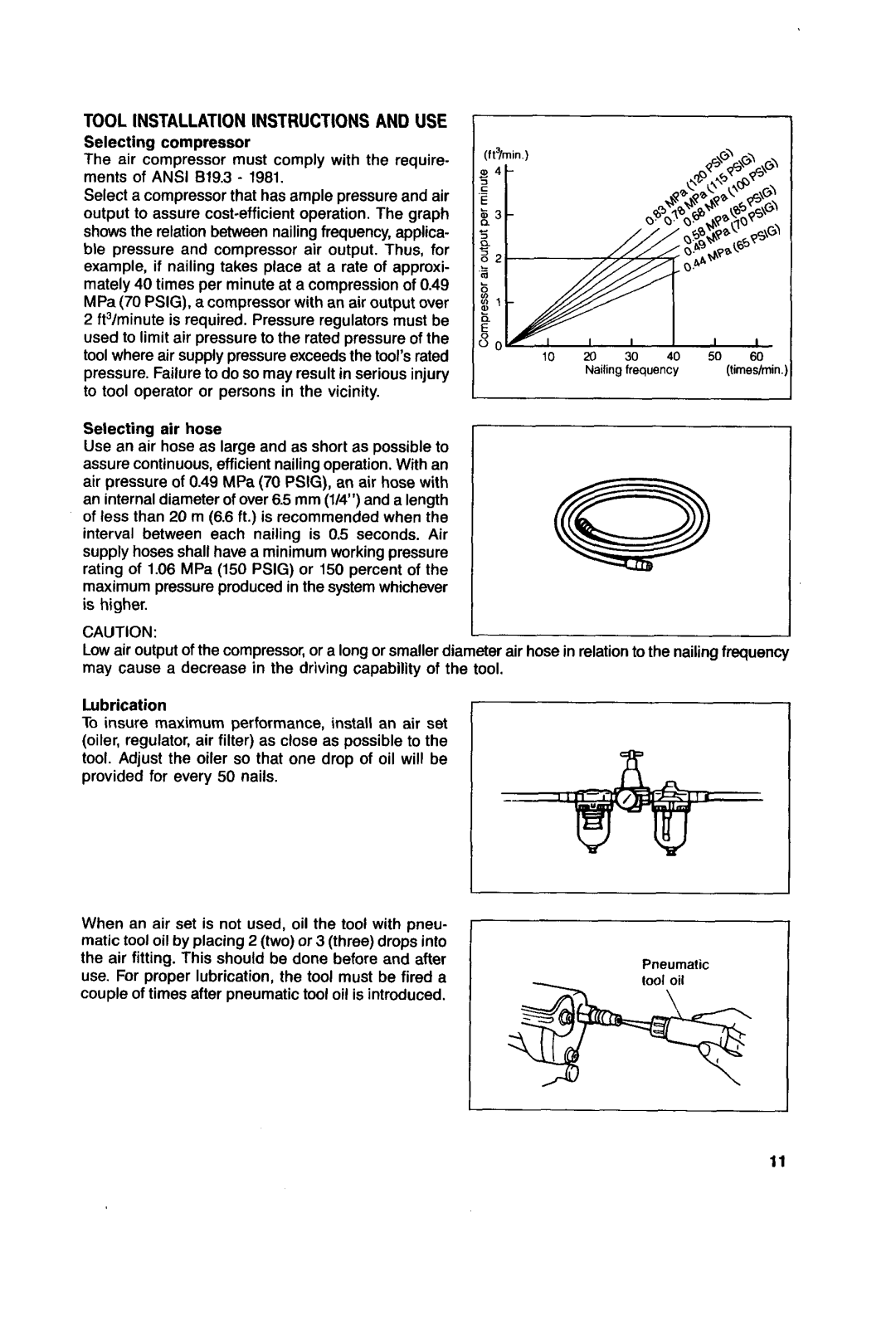

The air compressor must comply with the require-

ments of ANSI 819.3 - 1981. | 2 | 4 |

c |

| |

Select a compressor that has ample pressure and air | .- |

|

E |

| |

output to assure | 8 3 | |

shows the relation between nailing frequency, applica- | a |

|

.- | ||

ble pressure and compressor air output. Thus, for | a |

|

- |

| |

example, if nailing takes place at a rate of approxi- | a 2 | |

- |

| |

mately 40 times per minute at a compressionof 0.49 | m |

|

b |

| |

MPa (70 PSIG). a compressor with an air output over | t | l |

2 ft3/minuteis required. Pressure regulators must be | ii |

|

used to limit air pressure to the rated pressure of the | 5 |

|

tool where air supply pressure exceedsthe tool’s rated | 0 0 | |

|

| |

pressure. Failureto do so may result in serious injury |

|

|

to tool operator or persons in the vicinity. |

|

|

Selecting air hose |

|

|

Use an air hose as large and as short as possible to |

|

|

assure continuous, efficient nailingoperation. With an |

|

|

air pressure of 0.49 MPa (70 PSIG), an air hose with |

|

|

an internal diameter of over 6.5 mm (1/4”) and a length |

|

|

of less than 20 m (6.6 ft.) is recommendedwhen the |

|

|

interval between each nailing is 0.5 seconds. Air |

|

|

supply hoses shall have a minimum working pressure |

|

|

rating of 1.06 MPa (150 PSIG) or 150 percent of the |

|

|

maximum pressure produced in the system whichever |

|

|

is higher. |

|

|

CAUTION: | I |

|

Low air output of the compressor, or a long or smaller diameter may cause a decrease in the driving capability of the tool.

Lubrication

To insure maximum performance, install an air set (oiler, regulator, air filter) as close as possible to the tool. Adjust the oiler so that one drop of oil will be provided for every 50 nails.

10 20 30 40 50 60

Nailing frequency (timeshnin

air hose in relationto the nailing frequency

When an air set is not used, oil the tool with pneu- matic tool oil by placing 2 (two) or 3 (three) drops into

the air fitting. This should be done before and after IPneumatic use. For proper lubrication, the tool must be fired a

couple of times after pneumatic tool oil is introduced.

I

11