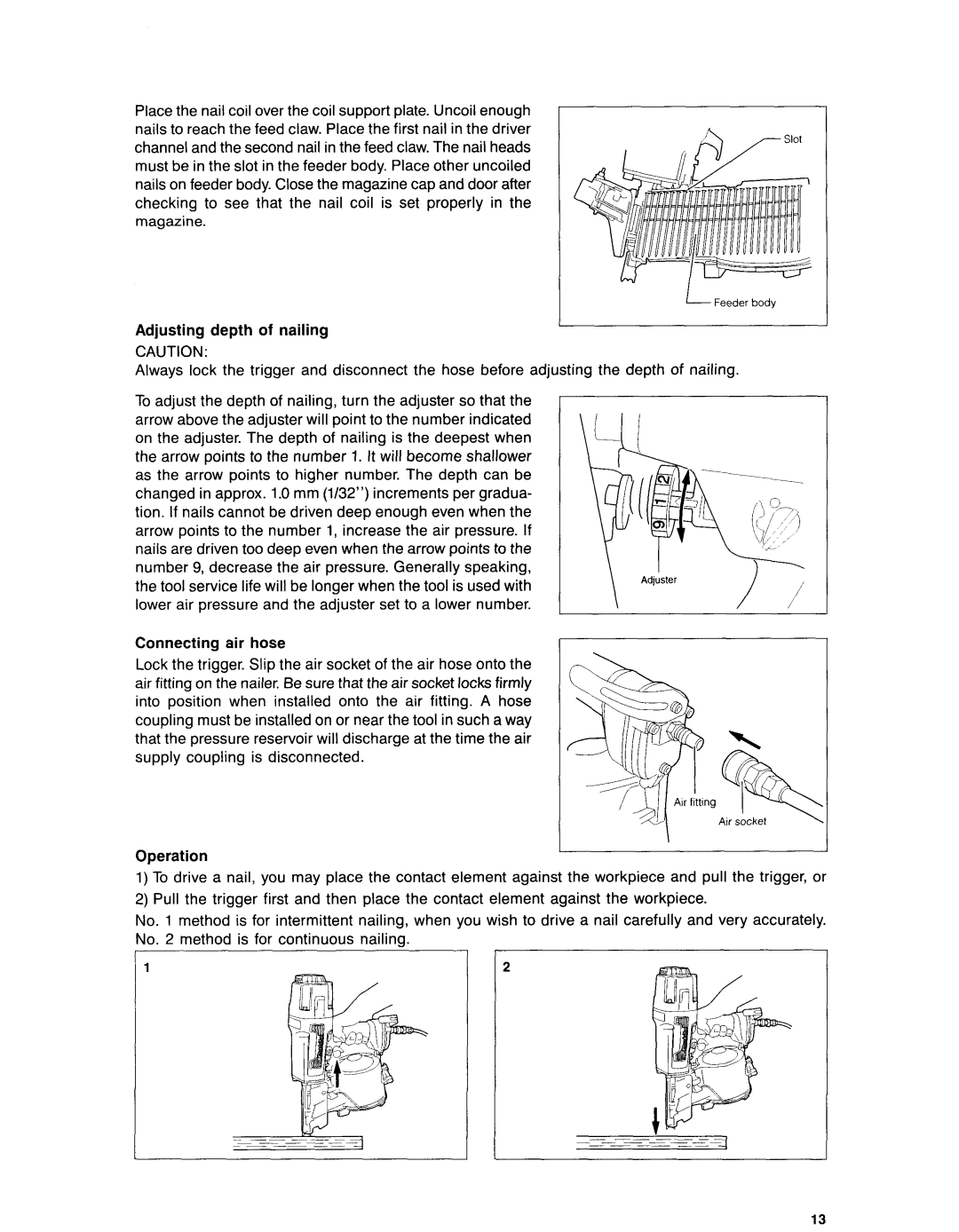

Place the nail coil over the coil support plate. Uncoil enough nails to reach the feed claw. Place the first nail in the driver channel and the second nail in the feed claw. The nail heads must be in the slot in the feeder body. Place other uncoiled nails on feeder body. Close the magazine cap and door after checking to see that the nail coil is set properly in the magazine.

“ iFeeder body

Adjusting depth of nailing | I |

|

CAUTION:

Always lock the trigger and disconnect the hose before adjusting the depth of nailing.

To adjust the depth of nailing, turn the adjuster so that the arrow above the adjuster will point to the number indicated on the adjuster. The depth of nailing is the deepest when the arrow points to the number 1. It will become shallower as the arrow points to higher number. The depth can be changed in approx. 1.Omm (1/32”)increments per gradua- tion. If nails cannot be driven deep enough even when the arrow points to the number 1, increase the air pressure. If nails are driven too deep even when the arrow points to the number 9, decrease the air pressure. Generally speaking, the tool service life will be longer when the tool is used with lower air pressure and the adjuster set to a lower number.

Connecting air hose

Lock the trigger. Slip the air socket of the air hose onto the air fitting on the nailer. Be sure that the air socket locks firmly into position when installed onto the air fitting. A hose

supply coupling is disconnected.

coupling must be installed on or near the tool in such a waysocket that the pressure reservoir will discharge at the time the air

Air

Operation

1)To drive a nail, you may place the contact element against the workpiece and pull the trigger, or

2)Pull the trigger first and then place the contact element against the workpiece.

No. 1 method is for intermittent nailing, when you wish to drive a nail carefully and very accurately.

No. 2 method is for continuous nailing.

r

1 | 2 |

13