DCS 6800I, DCS 6000I specifications

The Makita DCS 6000I and DCS 6800I are two formidable chainsaw models from a brand renowned for its commitment to durability, performance, and innovation. Both saws are designed for professional users who require power, efficiency, and precision in their cutting tasks.Starting with the DCS 6000I, it offers an impressive engine displacement of 59 cc, producing high torque and enabling effective cutting through thick wood with ease. Its lightweight design, weighing approximately 5.8 kg, ensures better maneuverability during extended use. The DCS 6000I incorporates a 20-inch guide bar, making it suitable for a variety of applications, from felling trees to milling logs.

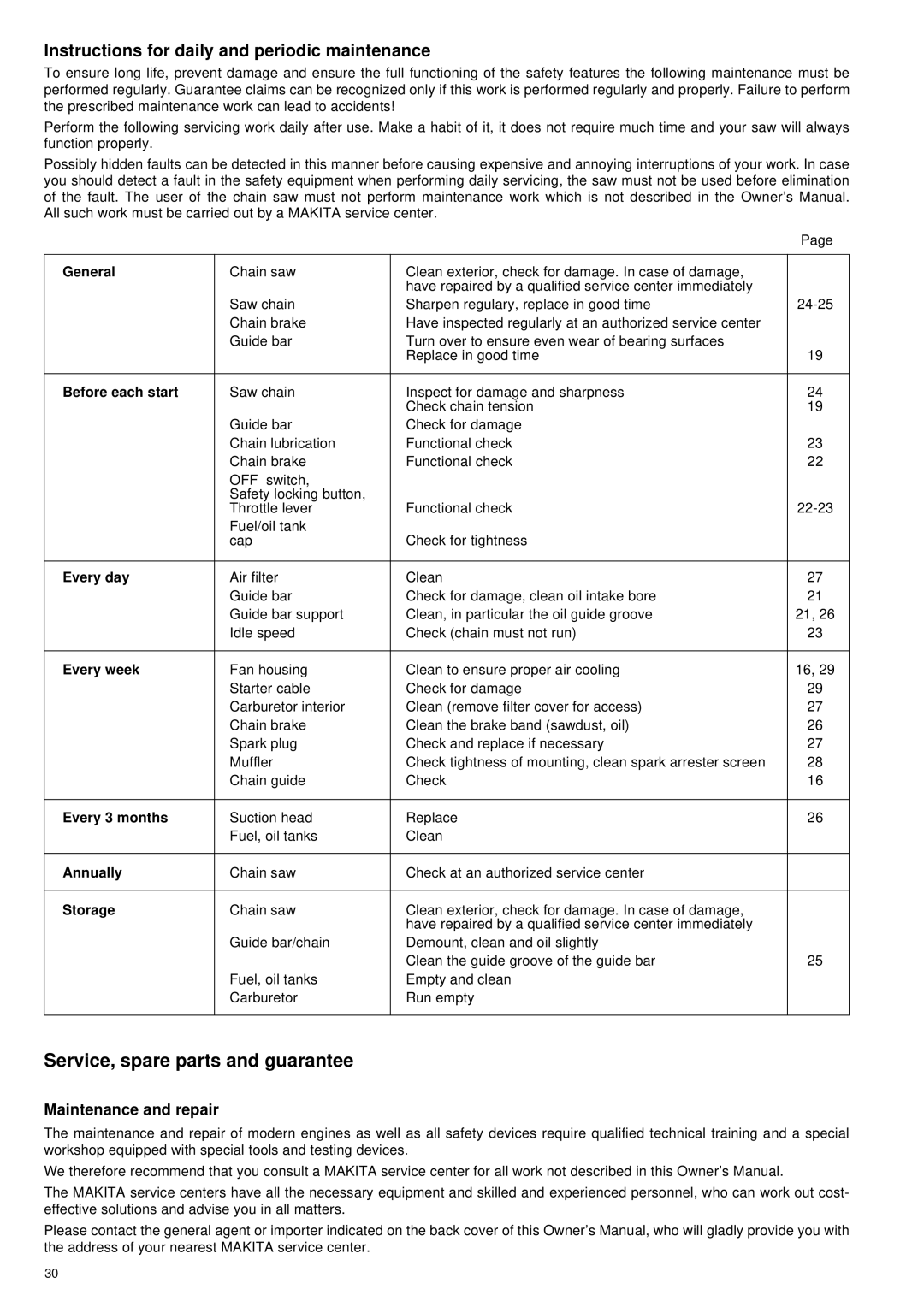

A key feature of the DCS 6000I is its advanced anti-vibration technology, which minimizes user fatigue and enhances comfort. The model is equipped with an automatic chain lubrication system that maintains optimal performance and prolongs the lifespan of the chain. The air cleaner is easily accessible and designed to filter out debris, ensuring clean air intake and efficient engine performance.

Moving on to the DCS 6800I, it takes power to the next level, featuring a robust 66 cc engine. This model is an ideal choice for professional users involved in heavy-duty cutting tasks. Weighing approximately 6.2 kg, it strikes a balance between power and manageability. Its 24-inch guide bar makes it a perfect fit for felling larger trees and undertaking more demanding forestry work.

The DCS 6800I is characterized by its high-performance oil pump that allows for adjustable flow rates, ensuring efficient lubrication based on the cutting conditions. Additionally, this model features an innovative decompression valve, allowing for easy starting and improved user experience. The DCS 6800I also has a semi-automatic choke that enhances startup efficiency.

Both models exhibit excellent build quality, featuring magnesium components that contribute to their lightweight yet robust structure. They also come with a tool-less air filter cover, facilitating ease of maintenance. Safety is a priority with both saws, equipped with chain brakes and throttle locks to prevent accidental starts.

In summary, the Makita DCS 6000I and DCS 6800I are exceptional chainsaws that cater to the needs of professional users. With advanced technologies, durable construction, and innovative features, these models are well-suited for various applications in forestry and landscaping, ensuring reliability, efficiency, and safety in all cutting tasks.