XSV10 specifications

The Makita XSV10 is an innovative cordless wet/dry vacuum designed to meet the needs of both professionals and DIY enthusiasts in various applications. With its robust features and advanced technologies, it offers exceptional performance, efficiency, and convenience.One of the standout characteristics of the XSV10 is its powerful 18V LXT battery platform, which ensures the vacuum operates seamlessly without the limitations of cords. Users can expect strong suction power that effectively handles both wet and dry debris, making it ideal for a wide range of tasks, from cleaning up spills to removing sawdust from construction sites.

The vacuum boasts a dual filtration system incorporating a HEPA filter, which captures harmful particles and allergens, ensuring clean air is expelled back into the environment. This feature makes the XSV10 particularly appealing for those concerned about indoor air quality, especially in environments such as homes, workshops, or offices.

In terms of design, the XSV10 is lightweight and portable, which enhances mobility during use. It features a robust carrying handle and a compact structure that allows for easy storage and transportation. The vacuum also incorporates a large-capacity dust bag and a debris canister, reducing the need for frequent emptying and increasing productivity.

Another key feature is its versatility, equipped with a range of accessories that enhance its usability on multiple surfaces. The vacuum comes with various nozzles and brushes suitable for different applications, from cleaning floors to getting into tight spaces.

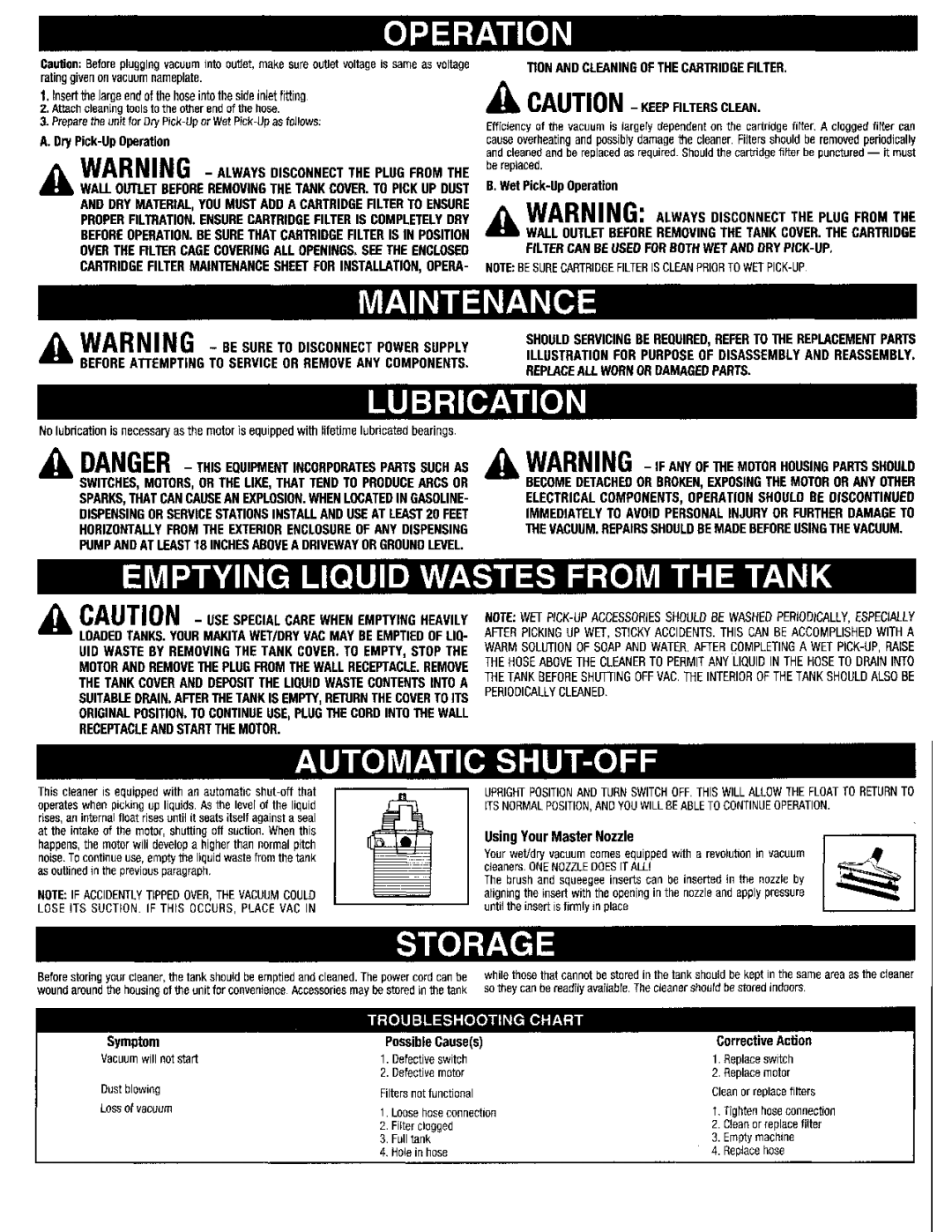

The XSV10 also features an easy-to-use control system, allowing users to switch between wet and dry vacuum modes effortlessly. Additionally, it has a built-in blower function, making it useful for tasks such as clearing debris from outdoor spaces.

Moreover, the XSV10 is engineered with durability in mind, using high-quality materials that withstand the rigors of daily use. Its rugged design is suitable for both construction sites and home improvements, ensuring longevity and reliability.

Overall, the Makita XSV10 is a highly functional and versatile cordless wet/dry vacuum that embodies the brand's commitment to innovation and quality. With its powerful performance, advanced filtration technology, and user-friendly design, the XSV10 is an excellent choice for those seeking a reliable cleaning solution.