Service Maintenance Guide

Area | Maintenance procedure | Frequency |

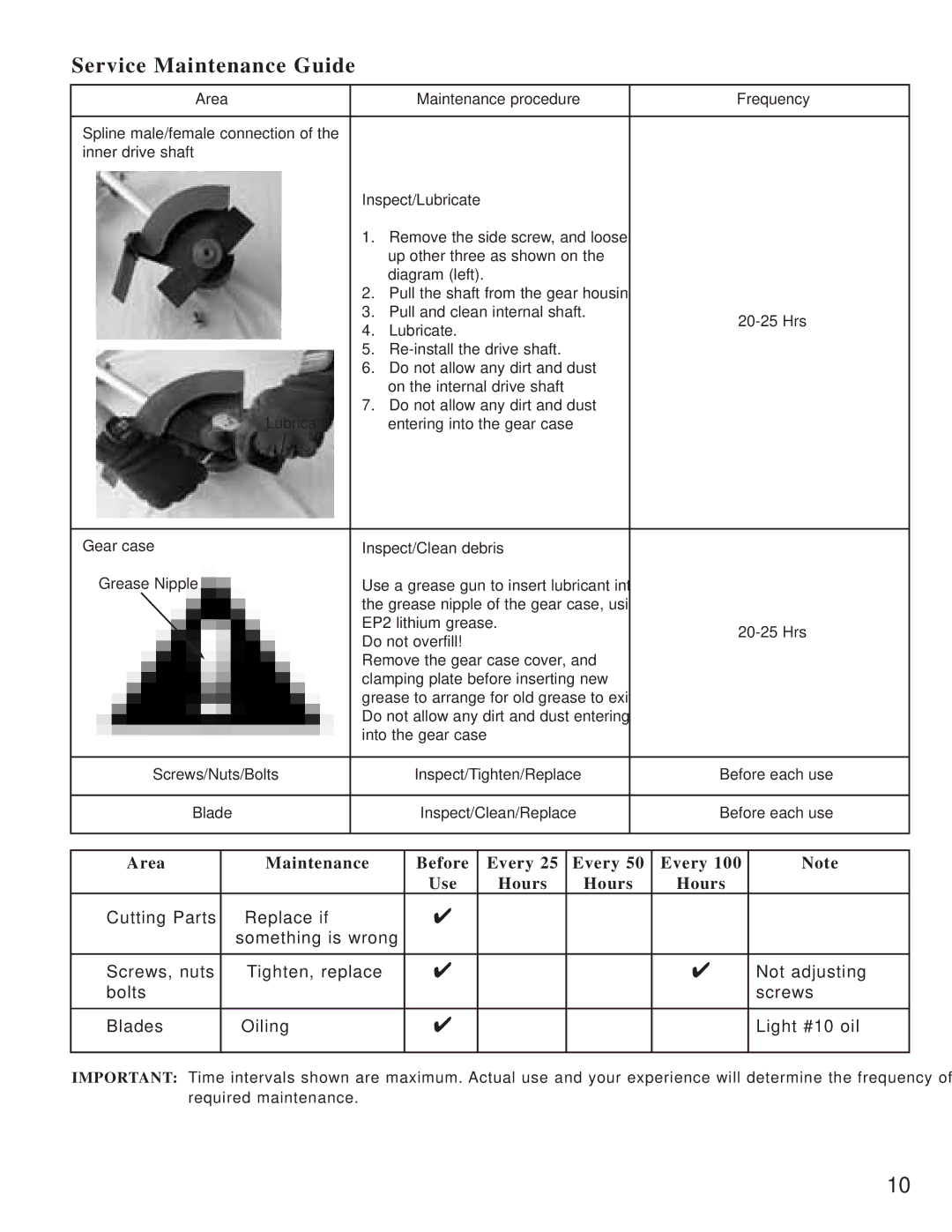

Spline male/female connection of the inner drive shaft

Inspect/Lubricate |

| ||

1. | Remove the side screw, and loosen |

| |

| up other three as shown on the |

| |

| diagram (left). |

| |

2. | Pull the shaft from the gear housing. |

| |

3. | Pull and clean internal shaft. | ||

4. | Lubricate. | ||

| |||

5. |

| ||

6. | Do not allow any dirt and dust |

| |

| on the internal drive shaft |

| |

7. | Do not allow any dirt and dust |

| |

Lubricate | entering into the gear case |

| |

Gear case | Inspect/Clean debris |

|

|

| |||||

Grease Nipple | Use a grease gun to insert lubricant into |

|

| ||||||

|

| the grease nipple of the gear case, using |

|

| |||||

|

| EP2 lithium grease. |

|

|

| ||||

|

| Do not overfill! |

|

|

| ||||

|

|

|

|

|

|

| |||

|

| Remove the gear case cover, and |

|

|

| ||||

|

| clamping plate before inserting new |

|

| |||||

|

| grease to arrange for old grease to exit |

|

| |||||

|

| Do not allow any dirt and dust entering |

|

| |||||

|

| into the gear case |

|

|

|

|

| ||

|

|

|

|

|

|

|

| ||

Screws/Nuts/Bolts | Inspect/Tighten/Replace |

| Before each use | ||||||

|

|

|

|

|

|

|

|

| |

Blade |

| Inspect/Clean/Replace |

| Before each use | |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Area |

| Maintenance | Before |

| Every 25 |

| Every 50 | Every 100 | Note |

|

|

| Use |

| Hours |

| Hours | Hours |

|

Cutting Parts |

| Replace if | ✔ |

|

|

|

|

|

|

|

| something is wrong |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screws, nuts |

| Tighten, replace | ✔ |

|

|

|

| ✔ | Not adjusting |

bolts |

|

|

|

|

|

|

|

| screws |

|

|

|

|

|

|

|

|

|

|

Blades |

| Oiling | ✔ |

|

|

|

|

| Light #10 oil |

|

|

|

|

|

|

|

|

|

|

IMPORTANT: Time intervals shown are maximum. Actual use and your experience will determine the frequency of required maintenance.

10