ADDITIONAL INSTRUCTIONS FOR EXPORT MODELS

(Not U.S. or Canada) Contact the distributor that sold the appliance or: Maytag International, 8700 W. Bryn Mawr Avenue, Chicago, Illinois USA 60631,

Maytag dryer models manufactured for operation on 60 Hz AC are not designed for use on 50 Hz AC electrical service and conversion of the product from 60 to 50 Hz operation is not recommended. For additional information on 50 Hz products, contact Maytag International. The electric service requirements can be found on the data label located on the front of the dryer behind the door.

EXPORT ELECTRIC MODELS

Export electric models are manufactured for operation on either 230/240 volt, 50 Hz or 220 volt, 60 Hz approved electric service. A

IMPORTANT: When permitted by local codes, the dryer electrical supply may be connected by means of a new power supply cord kit, marked for use with clothes dryers, that is agency listed, rated at 240 volts minimum, 30 amperes with two No. 10 copper wire conductors terminated with closed loop terminals,

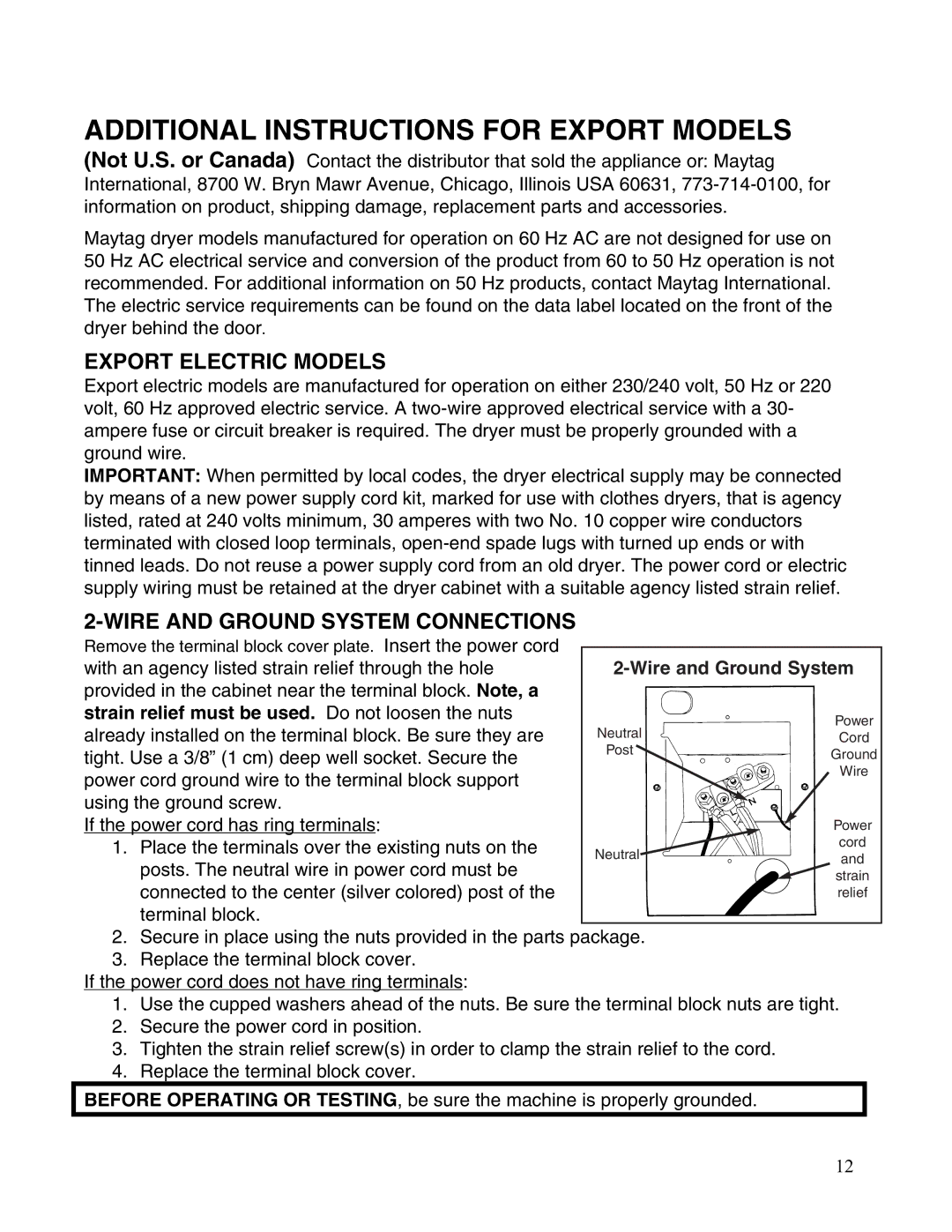

2-WIRE AND GROUND SYSTEM CONNECTIONS

Remove the terminal block cover plate. Insert the power cord |

|

| |

| |||

with an agency listed strain relief through the hole | |||

provided in the cabinet near the terminal block. Note, a |

|

| |

strain relief must be used. Do not loosen the nuts |

| Power | |

already installed on the terminal block. Be sure they are | Neutral | ||

Cord | |||

tight. Use a 3/8” (1 cm) deep well socket. Secure the | Post | Ground | |

| |||

power cord ground wire to the terminal block support |

| Wire | |

|

| ||

using the ground screw. |

|

| |

If the power cord has ring terminals: |

| Power | |

1. Place the terminals over the existing nuts on the | Neutral | cord | |

posts. The neutral wire in power cord must be | and | ||

| |||

| strain | ||

connected to the center (silver colored) post of the |

| relief | |

terminal block. |

|

| |

2.Secure in place using the nuts provided in the parts package.

3.Replace the terminal block cover.

If the power cord does not have ring terminals:

1.Use the cupped washers ahead of the nuts. Be sure the terminal block nuts are tight.

2.Secure the power cord in position.

3.Tighten the strain relief screw(s) in order to clamp the strain relief to the cord.

4.Replace the terminal block cover.

BEFORE OPERATING OR TESTING, be sure the machine is properly grounded.

12