Gas supply connection requirements

■Use an elbow and a ³⁄₈" flare x ³⁄₈" NPT adapter fitting between the flexible gas connector and the dryer gas pipe, as needed to avoid kinking.

■Use only

■This dryer must be connected to the gas supply line with a listed flexible gas connector that complies with the standard for connectors for gas appliances, ANSI Z21.24 or CSA 6.10.

Burner input requirements

Elevations up to 10,000 ft (3,048 m):

■The design of this dryer is certified by CSA International for use at altitudes up to 10,000 ft (3,048 m) above sea level at the Btu rating indicated on the model/serial number plate. Burner input adjustments are not required when the dryer is operated up to this elevation.

Elevations above 10,000 ft (3,048 m):

■When installed above 10,000 ft (3,048 m) a 4% reduction of the burner Btu rating shown on the model/serial number plate is required for each 1,000 ft (305 m) increase in elevation.

Gas supply pressure testing

■The dryer must be disconnected from the gas supply piping system during pressure testing at pressures greater than ½ psi.

Venting Requirements

![]() WARNING

WARNING

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

The dryer exhaust must not be connected into any gas vent, chimney, wall, ceiling or a concealed space of a building.

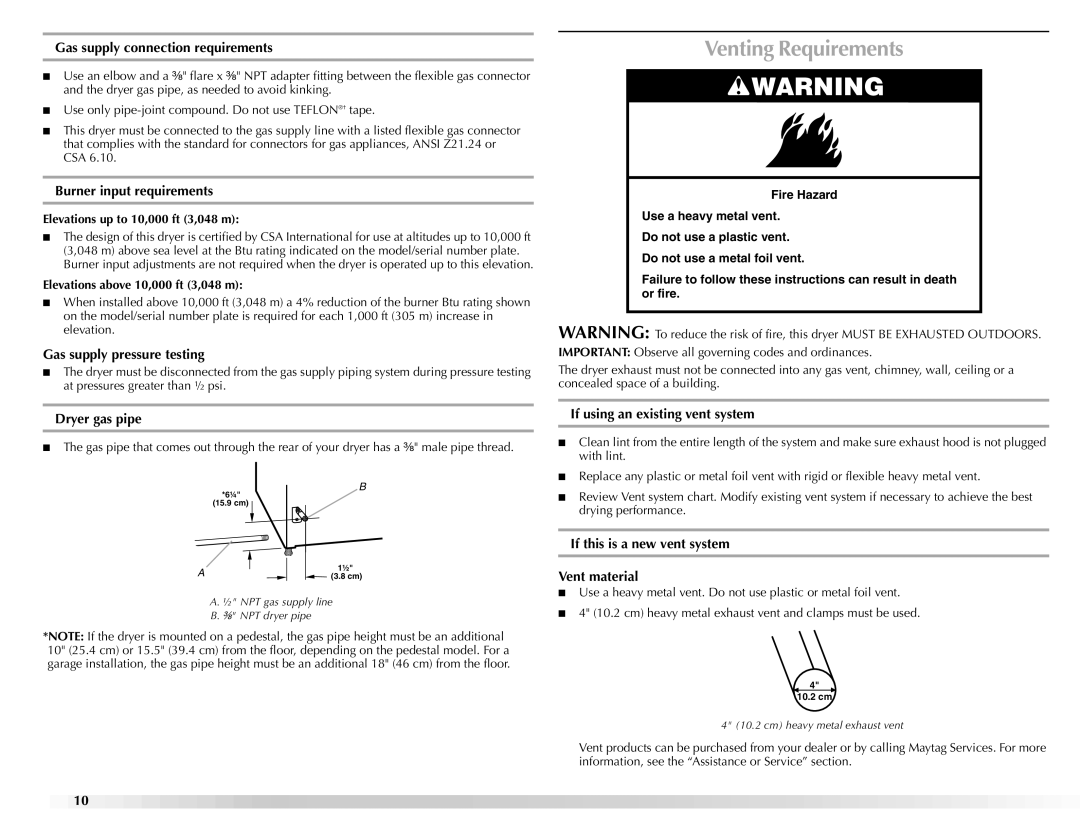

Dryer gas pipe

■The gas pipe that comes out through the rear of your dryer has a ³⁄₈" male pipe thread.

B

*6¼" (15.9 cm)

A |

| 1½" |

| ||

| (3.8 cm) |

A. ½" NPT gas supply line

B. ³⁄₈" NPT dryer pipe

*NOTE: If the dryer is mounted on a pedestal, the gas pipe height must be an additional 10" (25.4 cm) or 15.5" (39.4 cm) from the floor, depending on the pedestal model. For a garage installation, the gas pipe height must be an additional 18" (46 cm) from the floor.

If using an existing vent system

■Clean lint from the entire length of the system and make sure exhaust hood is not plugged with lint.

■Replace any plastic or metal foil vent with rigid or flexible heavy metal vent.

■Review Vent system chart. Modify existing vent system if necessary to achieve the best drying performance.

If this is a new vent system

Vent material

■Use a heavy metal vent. Do not use plastic or metal foil vent.

■4" (10.2 cm) heavy metal exhaust vent and clamps must be used.

4"

10.2 cm

4" (10.2 cm) heavy metal exhaust vent

Vent products can be purchased from your dealer or by calling Maytag Services. For more information, see the “Assistance or Service” section.

10