MAC 316 XT specifications

The McCulloch MAC 316 XT is a highly regarded chainsaw designed for both professional and home use, known for its reliability and performance. This versatile machine is particularly well-suited for cutting firewood, felling small to medium-sized trees, and performing various gardening tasks.One of the standout features of the MAC 316 XT is its powerful 35cc engine. This two-stroke engine delivers robust power while remaining relatively lightweight, allowing for easier maneuverability and handling during operations. The engine’s design fosters quick starting, thanks to the implementation of advanced primer bulb technology, which minimizes starting effort.

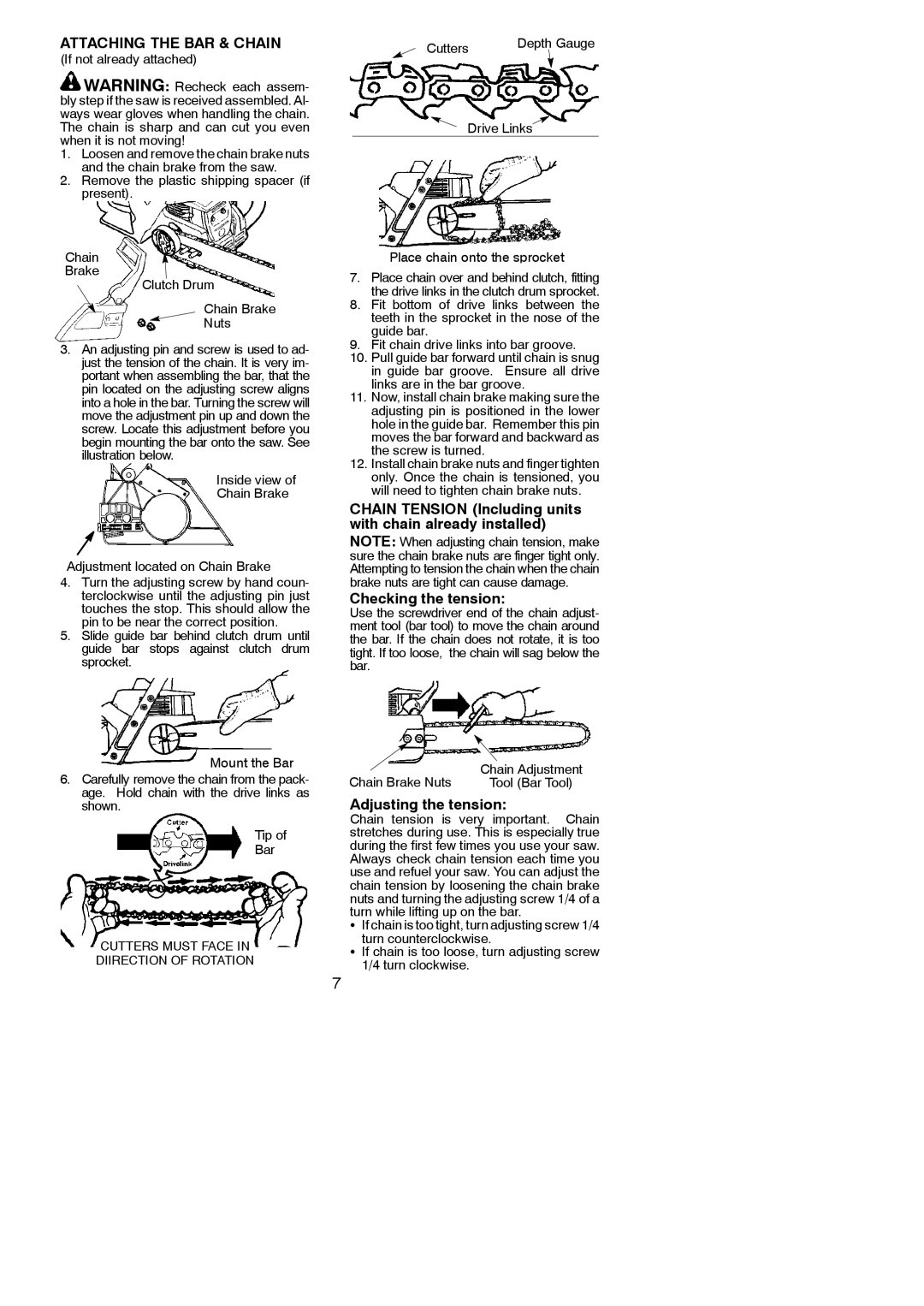

The chainsaw boasts a cutting bar length of 16 inches, providing an optimal balance between cutting power and ease of control. This size is ideal for tackling a variety of cutting jobs, from trimming branches to making clean cuts through larger logs. Coupled with a high-performance, low-vibration chain, users can expect smooth operation and increased cutting efficiency.

Ergonomics is a major consideration in the design of the MAC 316 XT. It features a comfortable grip that reduces operator fatigue during extended use. Additionally, the design includes an anti-vibration system that greatly diminishes the vibrations felt by the user, enhancing comfort and control while working.

For added safety, the MAC 316 XT is equipped with a chain brake that activates instantly in case of kickback, reducing the risk of accidents. The chainsaw also features a translucent fuel tank, allowing users to easily monitor fuel levels during operation, preventing interruptions in work.

Maintenance is made simple with the MAC 316 XT. The air filter is readily accessible for cleaning or replacement, which helps to prolong engine life by ensuring optimal airflow. The tool-less chain tension adjustment is another beneficial feature, allowing users to adjust the chain tension quickly without needing additional tools, thus enhancing the convenience of the device.

In terms of build quality, the MAC 316 XT utilizes durable materials, ensuring resilience against wear and tear. This chainsaw is designed to perform reliably over time, making it a sound investment for users looking for durability and efficiency in their outdoor tasks.

Overall, the McCulloch MAC 316 XT combines power, efficiency, and user-friendly design, making it a top choice for anyone looking to tackle tough cutting jobs with ease. Whether for professional use or DIY gardening projects, the MAC 316 XT delivers a balance of power and comfort, ensuring that users can work effectively without compromising safety or performance.