en ENGLISH

-Lock the spindle. Turn the clamping nut (12) clockwise using the

Releasing the clamping nut:

-Lock the spindle (see chapter 6.1). Turn the clamping nut (12) anticlockwise using the

7.Use

7.1Adjusting the speed (depending on features)

Set the recommended speed at the setting wheel (7).

Parting grinder and roughing discs, cup wheel, diamond parting wheel: high speed

Brush: medium speed

Grinding wheel: low to medium speed

Note: We recommend using our angle polisher for polishing work.

7.2Switching On and Off

Always guide the machine with both hands.

Switch on first, then guide the accessory towards the workpiece.

The machine must not be allowed to draw in additional dust and shavings. When switching

the machine on and off, keep it away from dust deposits. After switching off the machine, only place it down when the motor has come to a standstill.

Avoid inadvertent starts: always switch the tool off when the plug is removed from the

mains socket or if there has been a power cut. In continuous operation, the machine continues running if it is forced out of your

hands. Therefore, always hold the machine with both hands using the handles provided, stand in a safe position and concentrate.

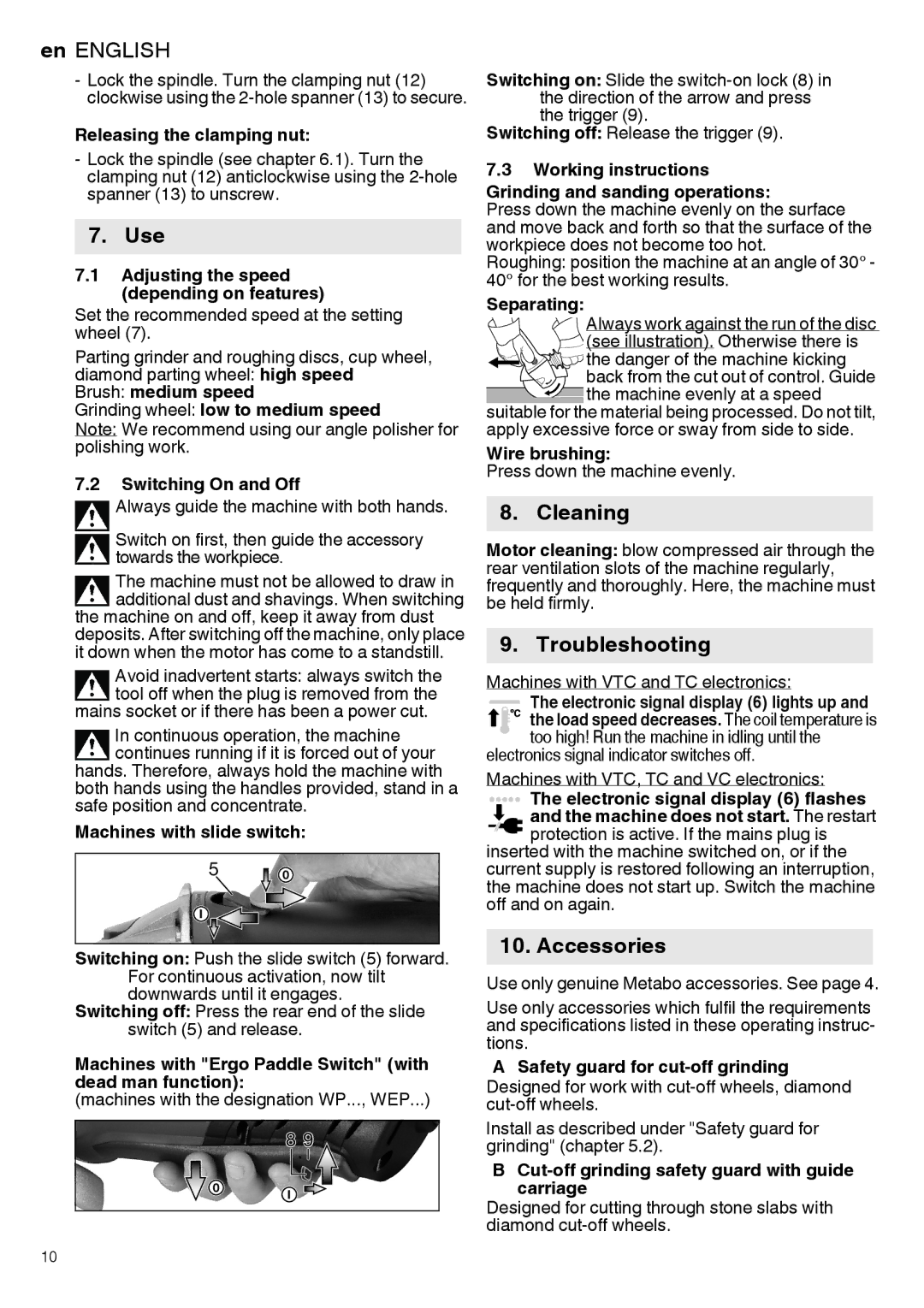

Machines with slide switch:

5![]() 0

0

I

Switching on: Push the slide switch (5) forward. For continuous activation, now tilt downwards until it engages.

Switching off: Press the rear end of the slide switch (5) and release.

Machines with "Ergo Paddle Switch" (with dead man function):

(machines with the designation WP..., WEP...)

8 9

0

I

Switching on: Slide the

Switching off: Release the trigger (9).

7.3Working instructions

Grinding and sanding operations:

Press down the machine evenly on the surface and move back and forth so that the surface of the workpiece does not become too hot.

Roughing: position the machine at an angle of 30° - 40° for the best working results.

Separating: Always work against the run of the disc

![]() (see illustration). Otherwise there is

(see illustration). Otherwise there is

![]() the danger of the machine kicking back from the cut out of control. Guide

the danger of the machine kicking back from the cut out of control. Guide

![]() the machine evenly at a speed suitable for the material being processed. Do not tilt, apply excessive force or sway from side to side.

the machine evenly at a speed suitable for the material being processed. Do not tilt, apply excessive force or sway from side to side.

Wire brushing:

Press down the machine evenly.

8. Cleaning

Motor cleaning: blow compressed air through the rear ventilation slots of the machine regularly, frequently and thoroughly. Here, the machine must be held firmly.

9. Troubleshooting

Machines with VTC and TC electronics:

The electronic signal display (6) lights up and the load speed decreases. The coil temperature is

too high! Run the machine in idling until the electronics signal indicator switches off. Machines with VTC, TC and VC electronics:

The electronic signal display (6) flashes ![]() and the machine does not start. The restart

and the machine does not start. The restart ![]() protection is active. If the mains plug is inserted with the machine switched on, or if the current supply is restored following an interruption, the machine does not start up. Switch the machine off and on again.

protection is active. If the mains plug is inserted with the machine switched on, or if the current supply is restored following an interruption, the machine does not start up. Switch the machine off and on again.

10. Accessories

Use only genuine Metabo accessories. See page 4. Use only accessories which fulfil the requirements and specifications listed in these operating instruc- tions.

ASafety guard for

Install as described under "Safety guard for grinding" (chapter 5.2).

B

Designed for cutting through stone slabs with diamond

10