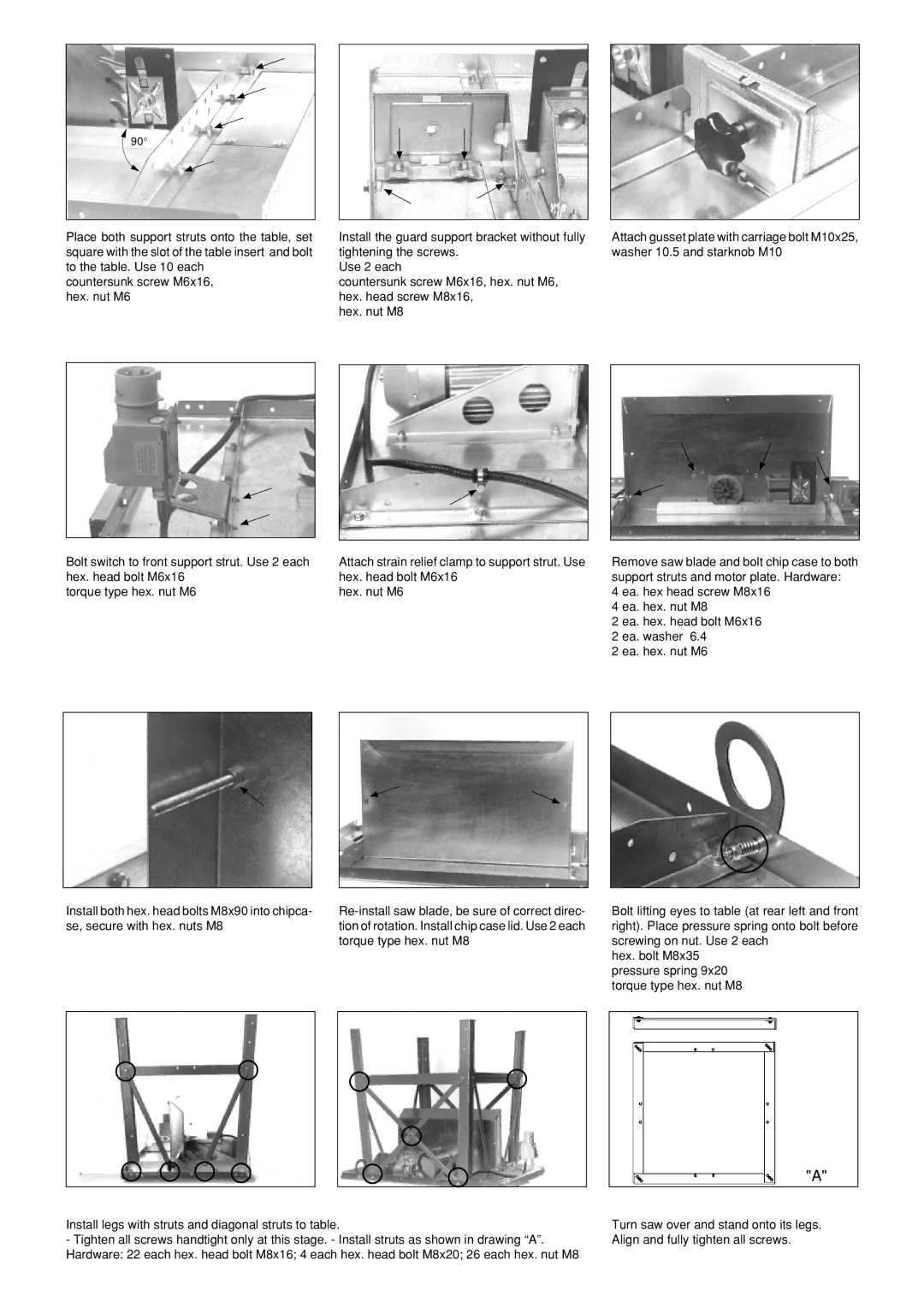

90°

Place both support struts onto the table, set square with the slot of the table insert and bolt to the table. Use 10 each

countersunk screw M6x16, hex. nut M6

Bolt switch to front support strut. Use 2 each hex. head bolt M6x16

torque type hex. nut M6

Install both hex. head bolts M8x90 into chipca- se, secure with hex. nuts M8

Install the guard support bracket without fully tightening the screws.

Use 2 each

countersunk screw M6x16, hex. nut M6, hex. head screw M8x16,

hex. nut M8

Attach strain relief clamp to support strut. Use hex. head bolt M6x16

hex. nut M6

Attach gusset plate with carriage bolt M10x25, washer 10.5 and starknob M10

Remove saw blade and bolt chip case to both support struts and motor plate. Hardware:

4 ea. hex head screw M8x16

4 ea. hex. nut M8

2 ea. hex. head bolt M6x16

2 ea. washer 6.4

2 ea. hex. nut M6

Bolt lifting eyes to table (at rear left and front right). Place pressure spring onto bolt before screwing on nut. Use 2 each

hex. bolt M8x35 pressure spring 9x20 torque type hex. nut M8

Install legs with struts and diagonal struts to table.

-Tighten all screws handtight only at this stage. - Install struts as shown in drawing “A”. Hardware: 22 each hex. head bolt M8x16; 4 each hex. head bolt M8x20; 26 each hex. nut M8

"A"

Turn saw over and stand onto its legs. Align and fully tighten all screws.